Stratasys announced a new 3D printer, the Origin Two.

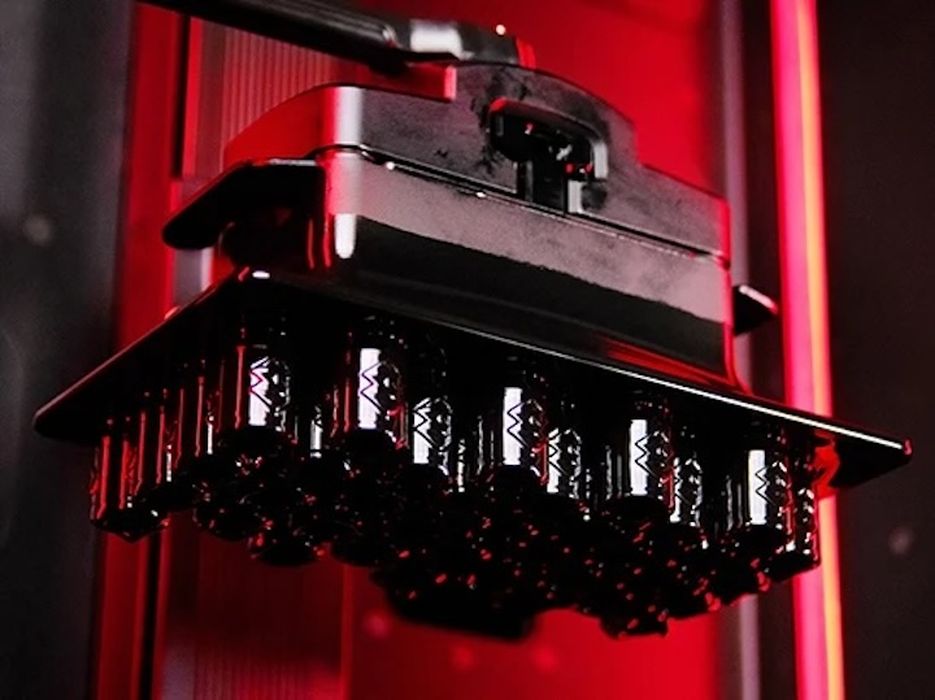

The Origin Two uses their P3 DLP 3D printing process, which stands for “Programmable PhotoPolymerization”. It’s a resin printing process, but one that involves significant real time feedback to precisely control heat, speeds and feeds. The result is parts described by Stratasys as “near injection mold quality”.

The Origin Two succeeds the Origin One 3D printer, which was first introduced way back in 2019 when Origin was a separate company. Later in 2021 Stratasys acquired Origin outright.

Stratasys did introduce a variant of the Origin One device for the dental industry, but the Origin Two appears to be the first new P3 device while under the Stratasys umbrella. It’s accompanied by a new post processing unit, the Origin Cure.

What’s different with the Origin Two aside from the external appearance? According to Stratasys, the “Two” includes a better DLP projector that can achieve up to 0.05mm accuracy for “validated applications”.

The Origin Two is capable of handling “high temperature and high viscosity materials”, up to 300C. That could be the most important new feature, as that could open up the possibility of using a much wider range of engineering materials. Some of those materials may not be printable on other 3D printers.

Stratasys said the Origin Two’s new light engine has the ability to print green parts with greater strength, which is quite desirable. Many 3D printers produce quite flimsy green parts that can be damaged before final processing.

Somehow the company has reduced the post processing time to “just a few minutes”. I would like to understand this better.

Finally, the Origin Two has a “validated” post processing workflow that has been extensively tested, and presumably can reliably produce parts.

That’s important because Stratasys bills the Origin Two as an “Industrial Production Printer”, where it would be operated continuously to manufacture larger quantities of parts.

There are currently 28 materials listed by Stratasys as certified for use with P3, including rigid, flexible and biocompatible (mostly dental) variants. However, they also offer an Open Materials program where “advanced operators” can use their OpenAM software to use third party materials for even more versatility.

The Origin Two is targeted at industry and offers a wide range of material options. This should permit Stratasys to market the device for quite a number of production applications.

Via Stratasys