I had a chat with SPEE3D CEO Byron Kennedy about their latest equipment and experiences.

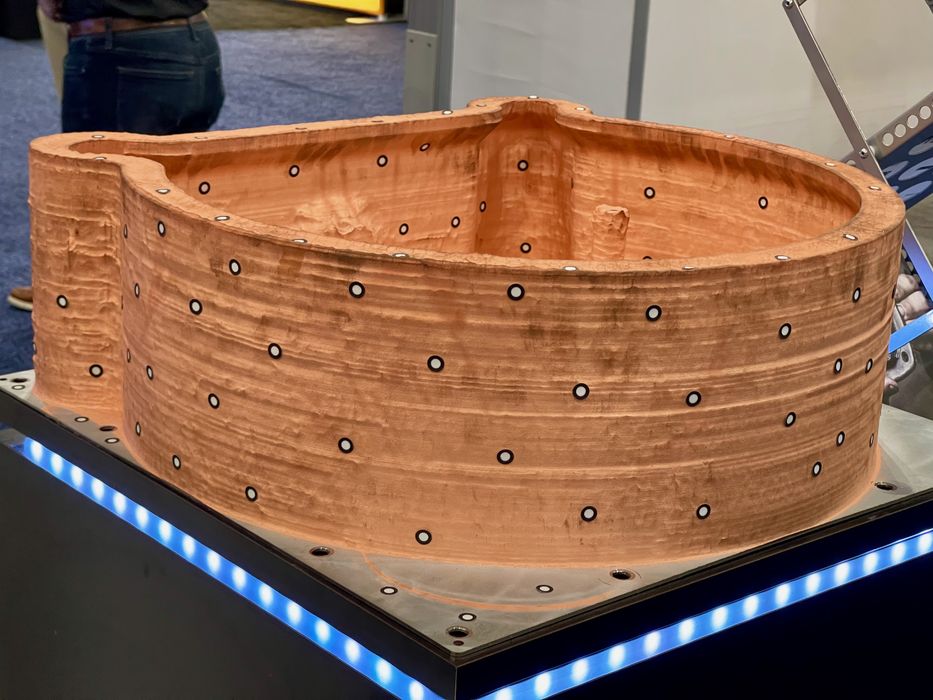

SPEE3D developed one of the most unusual 3D printing processes on the market, Cold Spray Additive Manufacturing (CSAM). The idea is to blast tiny metal particles at supersonic speeds towards a target. The impact energy bonds the molecules together, and 3D objects can be gradually built up. The technology works with a wide variety of metal powders, in including difficult-to-print copper.

CSAM differs from other 3D print processes in that it is far less susceptible to conditions. Typical competing LBPF metal 3D printers require carefully constructed air-managed buildings, but that’s not the case with CSAM.

In fact, SPEE3D bundles them into shipping containers for customers to deploy them in remote locations, starting with their XSPEED product. This capability attracted the attention of multiple military organizations around the world, and led to the company developing EMU, a shipping container solution targeted for military use.

https://www.fabbaloo.com/news/spee3d-unveils-emu-a-comprehensive-3d-printing-solution-for-military-field-operations

Kennedy explained:

“Militaries don’t want just the printer; they want parts. This requires finishing equipment, so we added a second shipping container for that.

It’s interesting what we learn on trials. For example, we now stock light welding equipment because it turned out that was needed. Testing is super important.”

What testing is underway? Spee3D is apparently working with six different militaries, including Japan, USA, UK, and UAE.

Kennedy added:

“There are ten units in Ukraine right now, producing real parts.”

I asked about the challenges of servicing these units, as they apparently are in a war zone. Kennedy explained:

“We can’t even get to the military bases. It requires a lot of time and trust.”

The testing by SPEE3D has revealed some interesting findings. Kennedy explained a key insight:

“We’ve found that the value of a part doubles for every 100 minutes it’s delivered quicker to the customer. We’ve done the math!”

But are military applications the focus? At the moment it seems to be for SPEE3D, but Kennedy explained they are looking at several other non-military industries.

One area is marine applications. Kennedy told us that CSAM is ideal for this area, because “it’s really easy to print on ships.”

However, breaking into that market is challenging, and Kennedy believes the company needs to find insiders to help find the way.

Nevertheless, SPEE3D has adapted CSAM to enable more potential applications. For example, they’ve changed the system from having a fixed nozzle and movable build plate to a fixed plate and movable nozzle. This enables far larger parts to be printed. They’ve also been working on their material capabilities, and aluminum bronze material would be of particular interest for marine applications.

It seems that SPEE3D is doing quite well as the company is finding profitable areas of application for their unique CSAM tech.

Via SPEE3D