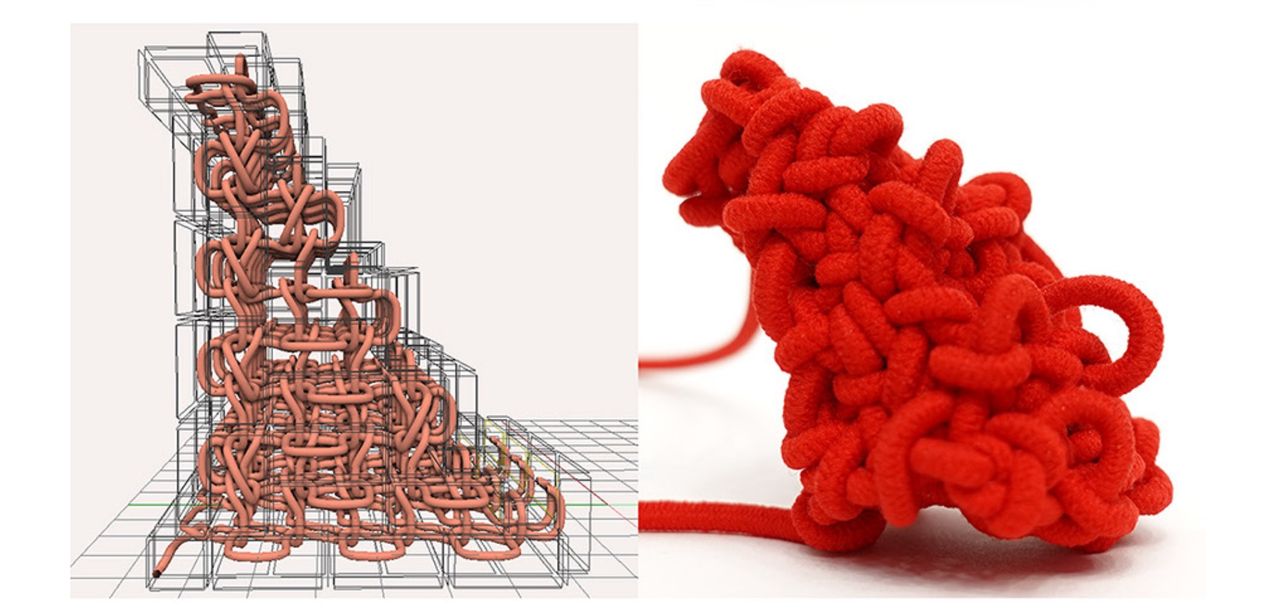

Researchers have developed an amazing new fabrication process they call “Solid Knitting”.

This is quite incredible: their technology includes a machine and software that can “knit” solid 3D objects from thread.

2D knitting machines have been around for centuries, and every cloth you’ve ever used almost certainly was made from one of those machines. They’re so familiar we don’t even think of them as “2D machines”. But with this development, there could be 2D or 3D knitting machines in the future.

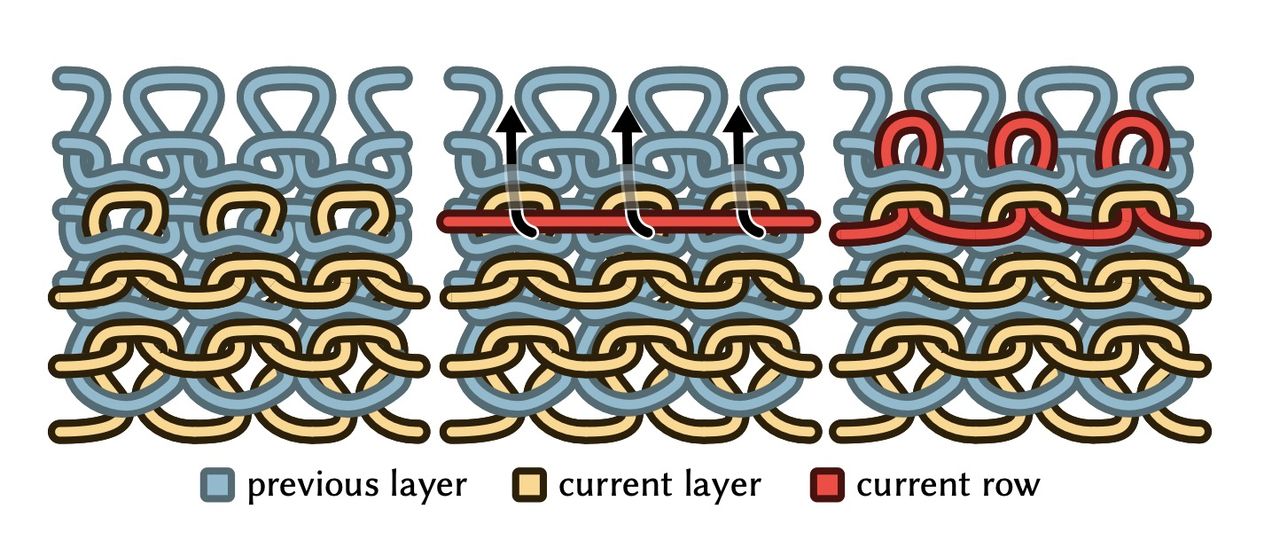

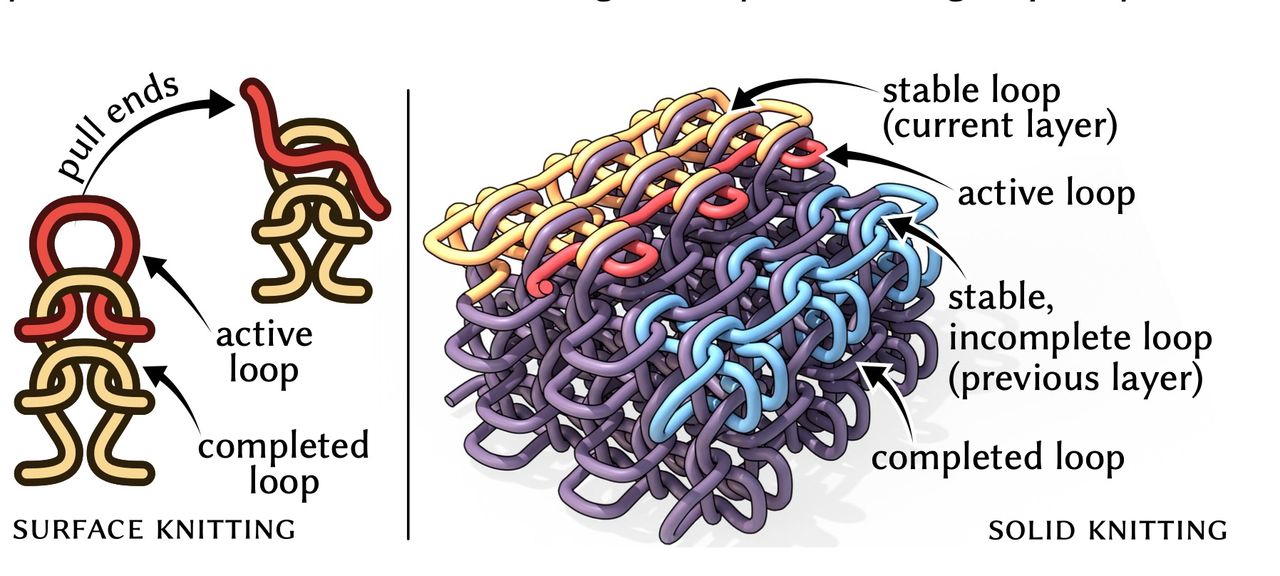

How does this work? The researchers developed a complex system that basically knits layers of thread on top of each other. This is quite similar to how most 3D printing processes work: layer-by-layer.

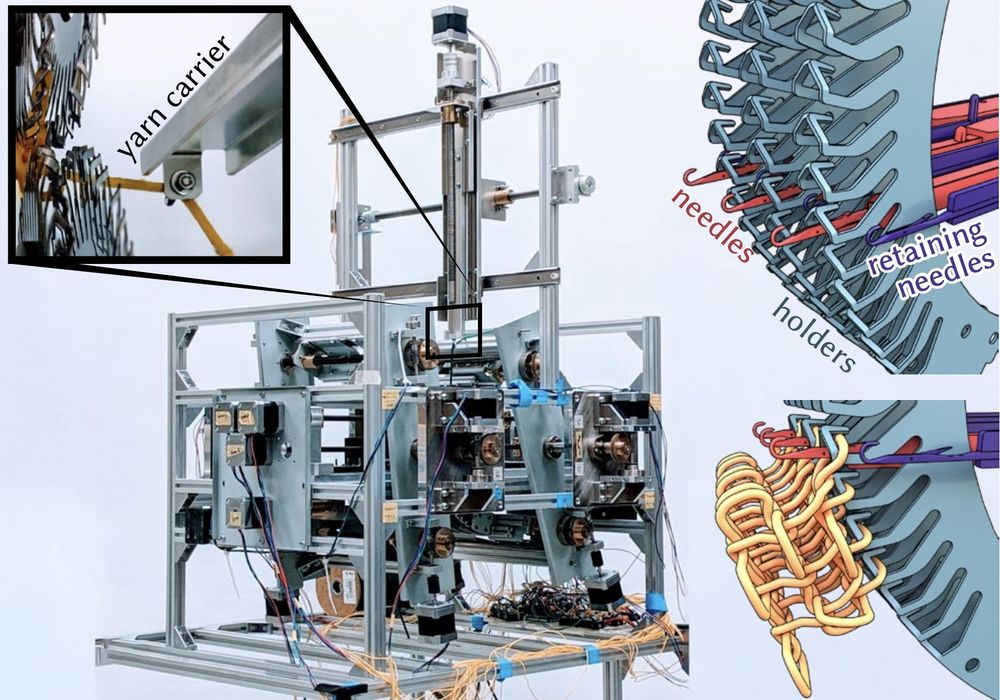

The layers are made using traditional knitting machine latch needles, but include extra hooks to hold up loops. These loops are then used to attach subsequent layers.

As the layers accumulate, you end up with a “solid” 3D object. It’s not really solid, as air can pass through the spaces between the threads, but it’s definitely not a 2D fabric.

In their paper you can review the extraordinarily complex method by which the layers are attached. While complex, they were able to build a machine that implemented the concept, and also develop software to generate the highly unusual machine instructions to run jobs.

This is a proof of concept, as manual intervention is required to set up the first layer, and tie off the final layer. However, I can see those as easy problems to solve were solid knitting ever to be commercialized.

Will solid knitting be commercialized? I strongly believe so, as it could have a wide range of possible applications. The materials used in a solid knitting machine would be far less expensive than what you’d find a typical 3D printer, and the applications would be wide enough to warrant large scale implementations.

The researchers suggest that it would be possible, for example to 3D knit a piece of furniture. The threads would provide a soft surface for sitting. They also suggest it would be possible to 3D knit footwear.

As you can see at top, it is entirely possible to make different solid geometries. This is not a machine that just prints “knitted bricks”.

The researchers list a number of areas for improvement in their process, such as use of different materials, implementing short loops for curves, variable stitch densities, additional shapes, and increasing reliability and consitency.

While their proof of concept implementation is really demonstrating the core technology, there are plenty of ideas that might appear in a commercialized version of solid knitting. I can imagine seeing automated loading, material swapping, and much more.

The current implementation of solid knitting is rudimentary, but proves the concept. It seems we’ve now entered the dot-matrix stage of this new fabrication technology.

Via GitHub