In this analysis, Charles R. Goulding and Preeti Sulibhavi unpack Siemens’ move to acquire Altair and what it means for the future of 3D printing and industrial automation.

Siemens is reportedly in discussions to acquire Altair Engineering Inc., in what could be a game-changing acquisition for the German engineering behemoth. Although there’s no guarantee that the current talks will lead to a definitive agreement, Altair’s market value pegged at approximately US$9.1 billion would be Siemens’ largest acquisition to date. This strategic move underscores Siemens’ continued growth from heavy machinery to software-centric growth areas, aimed at boosting profitability in sectors like factory automation.

Altair, a prominent player in the engineering software landscape, has seen its stock price rise by 27% this year, mostly by news of its potential sale. Let’s take a closer look at the company at the center of this acquisition and its range of 3D printing products.

Altair Inspire Print3D

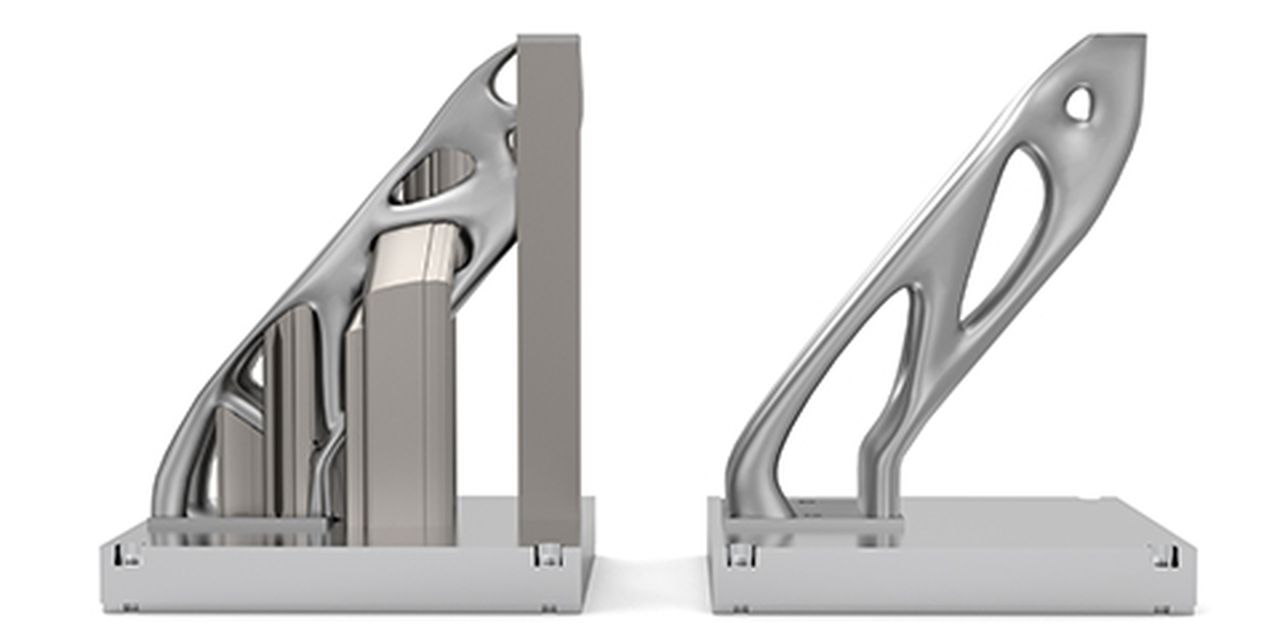

Altair’s Inspire Print3D application enables engineers to quickly understand changes to process or design that affect manufacturability, then export part and support structure geometry to major printer preparation software to produce the part. As a result, teams cut product development and additive manufacturing costs by reducing material usage, print times, and post-processing.

Starting from either topology optimization results or an imported CAD geometry, support structures that can be easily generated and optimized. Design alternatives can be quickly explored and evaluated without leaving the familiar Inspire user environment.

With Inspire’s unique set of simulation tools, users can quickly and easily explore and evaluate product feasibility to select the best manufacturing method for parts. For 3D printing, simulation of the part, its orientation, and the necessary support structures are essential to ensure materials are used efficiently and to avoid thermomechanical problems. The idea is to simulate manufacturing for metal binder jetting or powder bed fusion 3D printing processes, then create machine-ready outputs with 3DXpert by Oqton, available via the Altair Partner Alliance.

These are some of the key features of Inspire Print3D

Part and Supports Design

Generate and optimize support structures as part of the design process; interactively create and edit a wide range of support types within the same environment as the designed part.

Easy-to-learn Environment

The intuitive, process-driven user experience enables users to gain deep manufacturing insights quickly, driving faster and better design decisions.

Printing Analysis

The ability to run the embedded thermo-mechanical solver to accurately simulate the entire printing process from building and cooling to cutting and springback.

Identify Defects

Customers can easily detect and plot defects – large deformation, excessive heating, delamination – to aid design or process modification.

Materials and Printers

Users can select from the growing library of 3D printing materials and standard printers or apply a variety of advanced options for a customized setup.

Ready for Printing

Assess the part layer-by-layer to validate its geometry even before any 3D printing analysis is performed, then export a file containing the prepped part and supports.

Altair Sulis Software

Sulis is a design application for additive manufacturing (DfAM). It is a solution that enables engineers to create complex lattice structures and fluid flow channels for use across a range of industries, including aerospace, automotive, medical, and industrial machinery. It’s a 3D printing design software tool that gives users unmatched customization tools and manufacturing checks.

With a custom geometry kernel for tubes and an implicit design kernel for latticing, the highly automated 3D printing manufacturing design software features and easy drag-and-drop functionality provide a real time DfAM approach, enabling fast geometry creation for additive manufacturing (AM).

Key Features Include

One-click Lattice Creation

Choose between surface, strut, stochastic and planar lattices, or combine different lattice types in a single part. Also, choose between multiple coordinate systems to ensure lattices fit seamlessly within your CAD and AM design software models.

Tailor the Properties of Lattice Structures

Tailor the properties of your lattice structures by grading cell size and density across multiple axes. You can also reduce material usage and printing times by converting to a model with the desired shell thickness and interior lightweight lattice structure.

Range of Unit Cell Types

Allows users to select from a huge database of commonly used unit cells or define their own custom strut-based unit cells. This creates a new range of design opportunities, from tailoring mechanical properties to creating a variety of metamaterials – including auxetic structures.

Real-time Visual Feedback on Flow Paths

Dynamically edit patterned objects to create multiple spline objects while receiving real time feedback on your design. Also, you can edit complex fluid networks in real time using the click-and-drag tools.

Easy Conformal Geometry

Conform geometry over complex surfaces to increase packing efficiency, minimize material usage, or improve heat transfer between surfaces. You can also optimize the fluid network layout, routing, and interfacing components to be more compact and manufacturable.

Self-supporting Fluid Channels

Users may automatically analyze and compensate fluid channels to be self-supporting. This removes the need for painful internal support post-processing.

Altair & Kongsberg Defense (KDA)

Kongsberg Defense & Aerospace is Norway’s premier supplier of defense products and systems for command and control, surveillance, space, tactical communications, remote weapon stations and missile systems. KDA has extensive capabilities in advanced composite manufacturing and maintenance, repair, and overhaul (MRO) within the aircraft and helicopter market.

KDA is revolutionizing satellite antennas with lighter, faster, and more accurate designs through its innovative partnership with Altair.

Collaboration with Altair includes the following key features.

Generative Design

Generative design is the next-gen digital copilot for the design journey. Altair’s solutions integrate structural optimization with advanced techniques like topology, topography, and size/shape optimization for the development of lightweight, structurally efficient designs. No other solution on the market combines these capabilities with meshless finite element analysis (FEA), complete kinematic motion simulation, and advanced rendering. Leveraging artificial intelligence (AI) capabilities such as data mining, predictive models, and machine learning, Altair offers comprehensive design exploration through design of experiments (DoE) tools, efficient data storage, and streamlined process automation.

Implicit Modeling

Implicit modeling plays a crucial role in modern engineering simulation and 3D printing. With field-driven design, it enables engineers to generate and optimize aspects of complex systems with unprecedented speed, accuracy, and computational efficiency. Ideally suited for complex geometries, engineers can easily run FEA for complex lattice structures using embedded solvers in Altair Inspire for validation.

Unlock even more possibilities with Inspire’s ease of use and real-time editing to benefit from a novel, modern approach to field-driven design that seamlessly integrates with traditional geometry representations such as B-rep and solids.

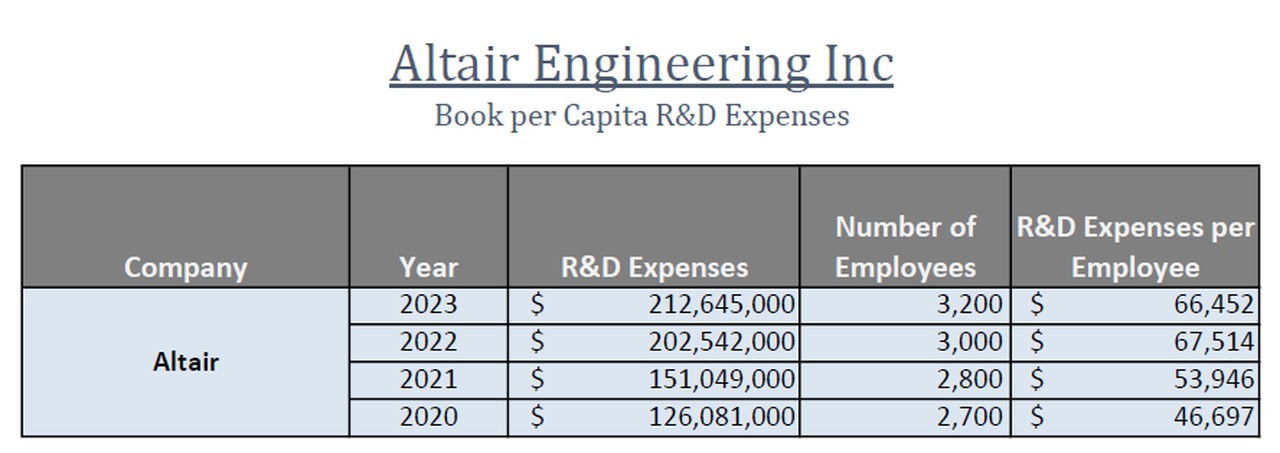

The R&D per capita table above presents large R&D spend that is substantially increasing each year.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Altair’s dedication and investment in research and development has positioned itself as a leader in its industry. With the help of 3D printing, it can advance even further, making the potential M&A with Siemens a win-win.