How should you print multiple copies of an object? The answer is more complex than you’d think.

I saw a question the other day about someone wondering whether it would be better to 3D print several copies all at once in the same job, or a single job that has all the copies.

The obvious answer would be to print them all at once. But there are quite a number of considerations before you answer the question. Let’s take a look at what could affect the answer to the question.

Travel Time

If you’re printing multiple copies in an FFF system, then the enemy is travel time. The FFF system must tediously trace all solid portions of each layer of the objects. If multiple objects are printed in the same job, then the toolhead must move between the objects repeatedly as each layer is completed. This can add considerable time to the print job. You can minimize this by placing the objects close to each other, but there will still be a delay.

On the other hand, if you print a single object, it would print, no travel time between objects is required, so the print completes faster.

Human Intervention

The single job approach would take longer, but requires no intervention: you don’t have to restart the job, unload print plates, etc. That would require the operator to be ready to act the instant the jobs complete.

But is that the case? Are you really going to hang around the printer for each of the 16 objects you are printing? What if the jobs will require overnight work? Are you willing to stay up all night changing prints?

Print Risk

There’s also the matter of risk. Every 3D printer has the possibility of a job failure, and that can happen in our multiple copy scenario.

If printing a single object, then a failure would cause the loss of exactly one copy. You’d lose that object and have to reprint it, and lose whatever material was used in the failure.

If printing all objects in a single job, then you’d lose ALL of the objects since they are printed layer by layer.

The question then becomes: what is the probability of failure on your equipment? What is the level of risk you are willing to take? Could you afford to lose the time and/or materials if a failure occurs?

Part Requirements

Exactly how fast are these parts needed? If they are needed quickly, then perhaps the single object approach would be best, as that would be the fastest option and mitigate the failure risk.

Note that a failure also means re-printing time. In the case of a time constraint, then you’d want to reduce that risk.

Print Process

There’s another factor here: the print process used. All of the above applies to the FFF process, where filament is extruded layer by layer. If you’re using a different 3D print process, then some of these factors change.

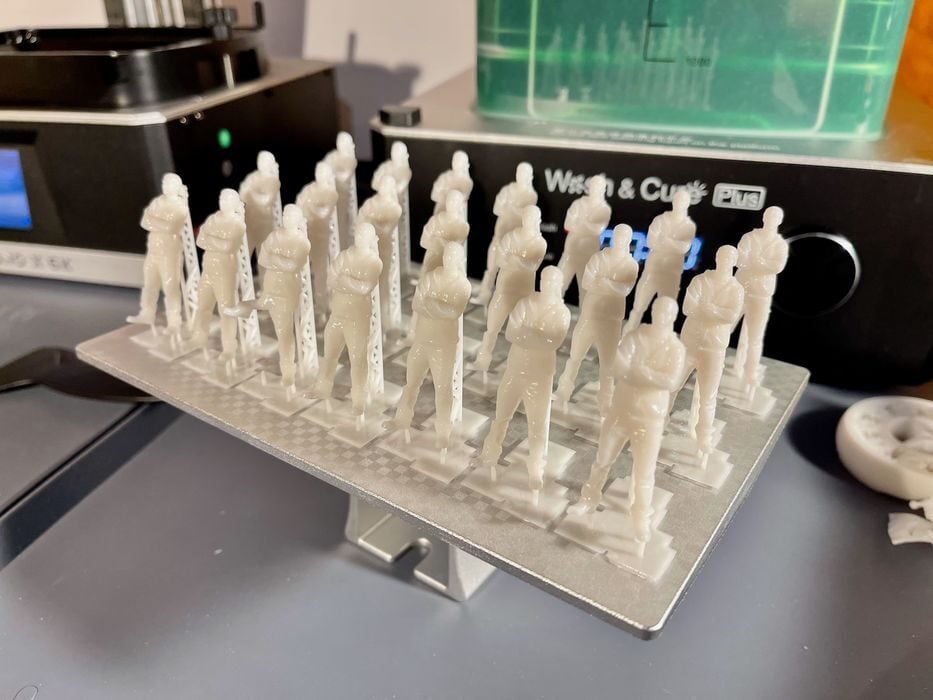

In the resin 3D printing processes, such as MSLA or DLP, the objects are printed differently. While they are still made layer by layer, the entire layer is printed all at once.

In other words, the print speed doesn’t depend on the amount of material being printed. Therefore, there is no “travel time” to account for. The time to print one object is the same as printing all of them, assuming they can all fit on the same build plate.

Summary

The question of how to print multiple copies is entirely dependent on your print process, your availability, your risk profile, and your project’s needs. It could be that the answer is different depending on each project.