Charles R. Goulding and Preeti Sulibhavi highlight Schneider Electric’s shift towards sustainable U.S. manufacturing, supported by 3D printing and federal incentives.

Schneider Electric, a global leader in energy management and automation, is headquartered in France and has significant market influence worldwide. Despite its large US presence, many Americans remain unaware of Schneider Electric’s contributions to energy efficiency, sustainability, and digital transformation. With a workforce of 168,000 employees and a market capitalization of US$149 billion, Schneider Electric has built a reputation for delivering essential products in renewable energy, automation, and building management systems.

In recent years, Schneider has strategically leveraged opportunities in the US, spurred by tax incentives from the Inflation Reduction Act (IRA) and other policies. This focus includes integrating advanced technologies such as 3D printing into their processes and products, enhancing their competitiveness, reducing costs, and promoting sustainable production methods. Here, we explore Schneider Electric’s core strengths, the role of the IRA, and how their use of 3D printing exemplifies their innovative approach to manufacturing and energy management.

Schneider Electric: A Broad Range of Electrical and Automation Products

Schneider Electric’s extensive product portfolio covers critical areas in energy management and digital automation:

- Solar Components: Schneider Electric provides key components for rooftop solar installations. With the rapid growth of rooftop solar adoption, Schneider’s products have gained traction in supporting renewable energy goals and meeting the demand for sustainable energy solutions.

- Heat Pumps and Building Controls: The company is also a key player in HVAC (heating, ventilation, and air conditioning) systems, offering heat pumps and building controls that align with increasing energy efficiency demands. These systems optimize energy consumption and create environmentally sustainable solutions for both commercial and residential applications.

- Data Centers and Digital Transformation: Data centers are another critical sector Schneider serves. The company supplies power management and cooling solutions designed to ensure reliability, efficiency, and sustainability. Data centers are high-energy consumers, making Schneider’s products integral to reducing environmental impact while meeting the growing need for data storage and processing.

With products catering to diverse industries, Schneider is positioned as a key contributor to the future of sustainable energy and automation in the US.

Capitalizing on US Tax Incentives: A Strategic Advantage

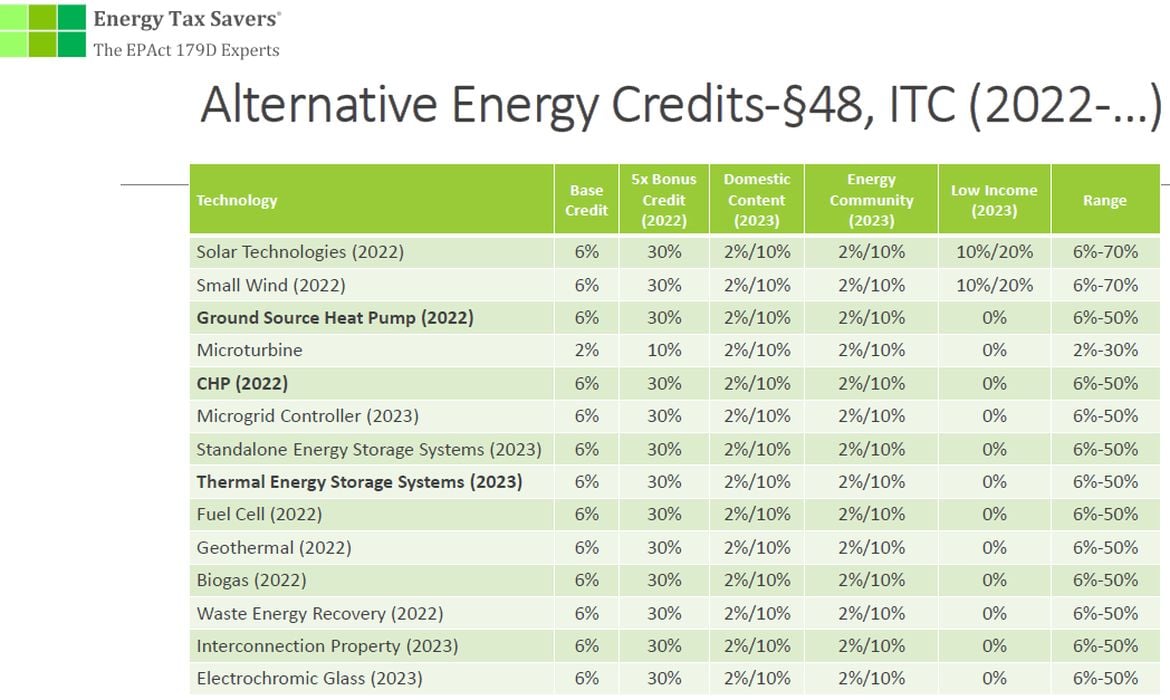

Schneider Electric is well-positioned to benefit from US federal incentives for clean energy and energy-efficient infrastructure. The Inflation Reduction Act (IRA), introduced in 2022, provides extensive tax incentives to companies investing in alternative energy technologies and energy-efficient building products. Schneider Electric has taken advantage of these provisions, aligning its growth strategy with evolving US policies and standards.

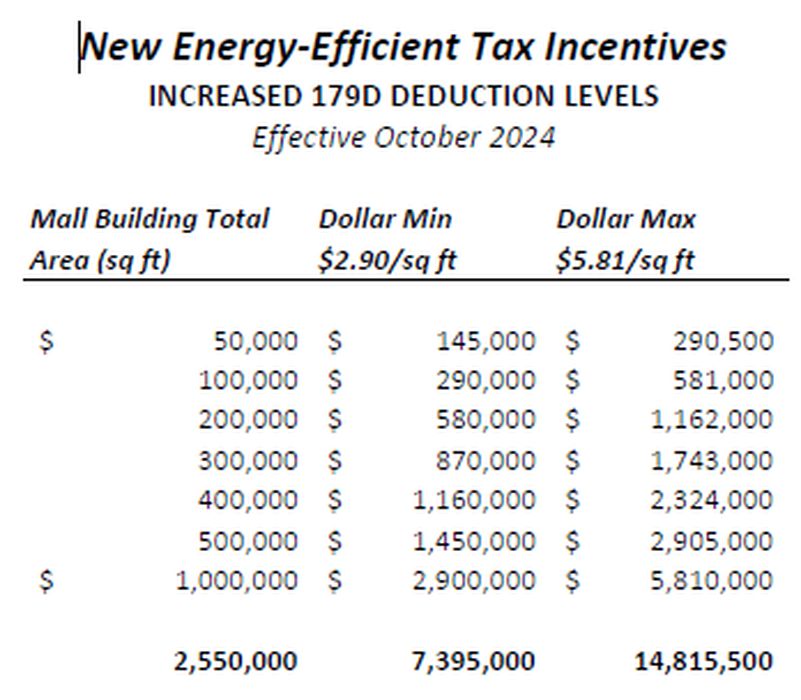

The 179D tax deduction has proven particularly valuable for Schneider. This incentive provides up to US$5.91 per square foot for qualifying energy-efficient buildings, benefiting Schneider’s building control products and systems. By offering solutions that meet or exceed energy efficiency standards, Schneider not only helps customers cut costs and reduce carbon footprints but also positions itself as a preferred supplier in the US market. The increased incentives amplify Schneider’s growth opportunities, creating favorable conditions for expanding its influence in the US as it navigates the challenging European economic climate.

In September 2024, Schneider Electric, the global leader in the digital transformation of energy management and automation, announced having facilitated several new “Tax Credit Transfer” (TCT) deals by Kimberly-Clark Corporation, one of the world’s leading manufacturers of personal care and hygiene products and owner of household brands such as Huggies, Kleenex, Scott, Kotex, Cottonelle, Poise, Depend, and Wypall. TCT agreements allow for the transfer of tax credits from one company that is unable to benefit from the incentives at a given time, to another company that can benefit, though at a discounted rate. Additionally:

- New TCT agreements contribute to supporting America’s clean energy transition through tax credit transferability under the Inflation Reduction Act (IRA).

- Projects are helping to pave the way for additional investments from the voluntary market to support developers fostering renewable energy projects.

- Through strategic guidance from Schneider Electric, Kimberly-Clark will fund four new battery energy storage projects, demonstrating its support of critical grid resiliency.

How Schneider Electric Uses 3D Printing to Innovate and Reduce Costs

Schneider Electric has incorporated 3D printing technology across several areas of its business, utilizing its advantages for prototyping, manufacturing, and even final production. This technology allows Schneider to improve production speed, cut costs, and reduce waste, contributing to the company’s sustainability objectives. Here are four specific applications of 3D printing within Schneider Electric:

- Customized Parts for Electrical Products

- Schneider Electric leverages 3D printing to manufacture customized components for its wide array of electrical products, especially in lower-volume production runs where traditional manufacturing would be costly. For example, Schneider has used 3D printing for low-voltage and medium-voltage switchgear components. These parts can be complex and specific to customer needs, and 3D printing enables rapid customization, resulting in reduced lead times and minimized material waste Prototyping of New Product Designs.

- 3D printing has become an integral part of Schneider’s design and prototyping process. By creating prototypes for new products in-house, the company can significantly reduce development times and respond quickly to market demands. In collaboration with 3D printing firms, Schneider’s teams have developed prototypes for IoT-enabled devices and advanced building control systems in a fraction of the time it would traditionally take. This rapid prototyping approach fosters faster innovation cycles and supports Schneider’s goal of remaining at the forefront of technological advancement in energy management.

- Manufacturing for Sustainable Production

- Schneider Electric prioritizes sustainability across its production methods, and 3D printing plays a key role. The company’s sustainability efforts include using 3D printing to minimize waste in production. For instance, modular circuit breakers and power distribution panels are now partially produced through additive manufacturing, allowing Schneider to manufacture only the required amount of material for each component. This targeted approach minimizes excess material use, contributing to Schneider’s overarching commitment to sustainable production.

- On-Demand for Legacy Systems

- Maintaining older electrical systems can pose a challenge due to discontinued parts and high replacement costs. Schneider has addressed this challenge by using 3D printing for on-demand manufacturing of spare parts for legacy systems. This practice extends the life of existing systems, reduces downtime for customers, and eliminates the need for large inventories of rarely used parts. By printing parts as needed, Schneider meets customer demands efficiently while minimizing storage and material expenses.

Through these applications, Electric exemplifies how 3D printing can enhance operational efficiency and support sustainable practices in the energy and automation sectors.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Schneider Electric’s Strategic Shift to the US and the Role of 3D Printing

Schneider Electric is navigating a challenging economic environment in Europe while finding significant growth opportunities in the US, thanks to large tax incentives and an increasing demand for sustainable energy solutions. The Inflation Reduction Act and other government policies present an ideal environment for Schneider to expand its influence in the US market.

3D printing is a prime example of how Schneider is embracing innovation to maintain its competitive edge. From custom components to sustainable production processes, Schneider is leveraging this technology to improve cost efficiency, enhance flexibility, and meet the specific needs of its customers. By using additive manufacturing for on-demand spare parts, rapid prototyping, and sustainable production, Schneider is setting an example for other companies in the energy and automation sectors.

As Schneider Electric continues to expand in the US, its blend of technological innovation and commitment to sustainable practices positions it to thrive amidst changing market dynamics. With strategic investments in 3D printing and alignment with federal incentives, Schneider is set to remain a critical player in energy management and automation well into the future. This approach not only strengthens its standing in the US market but also underscores Schneider’s role as a leading global innovator in sustainable energy solutions.

Conclusion

The weak European economy is currently facing many challenges. Schneider like Bosch is an example of a leading European multinational shifting to benefit from the large clean energy tax incentives now available in the US.