Charles R. Goulding and Andressa Bonafe explore how 3D scanning technology is revolutionizing industries from healthcare to entertainment, offering precise digital replicas that enhance efficiency and innovation.

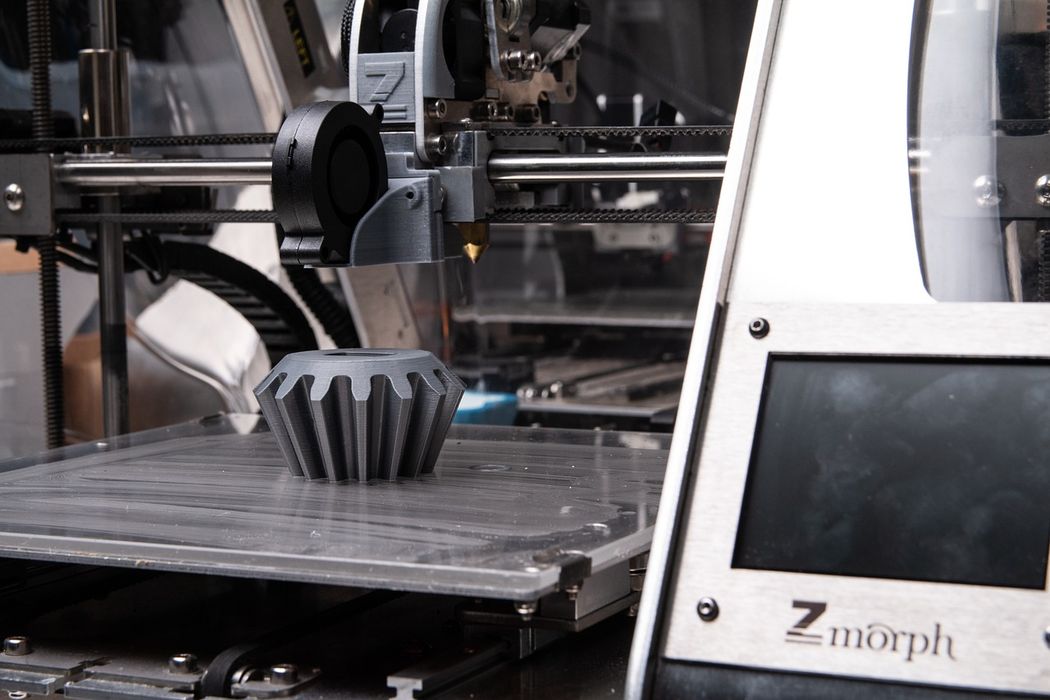

3D scanning plays a pivotal role in enabling the creation of precise digital replicas of physical objects. Through techniques like laser scanning or structured light scanning, 3D scanners capture the geometry and surface texture of real-world objects, converting them into digital models. This process is crucial for reverse engineering, prototyping, customization, and quality assurance in various industries. By providing accurate digital representations, 3D scanning facilitates the seamless integration of real-world objects into the 3D printing workflow, allowing for the replication of complex shapes and intricate details with high fidelity. Moreover, 3D scanning significantly reduces the time and effort required for designing objects from scratch, accelerating the overall production process and enhancing the efficiency of 3D printing technologies.

3D scanning applications

3D scanning is widely used across various industries, often in conjunction with 3D printing. The following paragraphs illustrate the versatility of applications and their impact across very diverse domains:

- Automotive: Automotive manufacturers employ 3D scanning to capture intricate geometries of existing parts, such as engine components or body panels. These scans are the foundation for creating replacement parts or designing custom modifications.

- Aerospace: In aerospace engineering, 3D scanning ensures precise measurements of aircraft components. It aids in creating lightweight, optimized parts for aircraft interiors, engines, and structural elements.

- Architecture and Construction: Architects and builders utilize 3D scanning to create detailed as-built models of existing structures. These models inform renovation plans, retrofitting, and preservation efforts. Additionally, 3D-printed architectural models help visualize designs.

- Healthcare: Medical professionals rely on 3D scanning for patient-specific applications. For instance, orthopedic surgeons use scans to design personalized implants, while dentists create custom dental crowns and bridges.

- Art and Cultural Heritage: Museums and art restoration experts use 3D scanning to document and preserve artifacts. It aids in creating replicas, restoring damaged sculptures, and analyzing historical objects.

- Consumer Goods: Companies producing consumer goods, such as electronics or wearables, use 3D scanning to customize product designs. For instance, personalized phone cases or ergonomic computer peripherals benefit from this technology.

- Fashion and Jewelry: Fashion designers and jewelers leverage 3D scanning to create intricate and customized pieces. Scanning human bodies also helps tailor clothing and footwear.

- Energy and Oil Industry: 3D scanning assists in inspecting oil rigs, pipelines, and other critical infrastructure. It ensures accurate measurements for maintenance and repairs.

- Education and Research: Educational institutions and research labs use 3D scanning to study fossils, archaeological artifacts, and anatomical structures. It enhances learning and scientific exploration.

- Entertainment and Gaming: 3D scanning captures real-world objects or actors for use in video games, movies, and virtual reality experiences.

Recent developments in 3D scanning

The 3D scanner market has expanded significantly, offering a wide range of options in terms of size, capabilities, and price. Whether you’re a student, hobbyist, or professional, there’s a scanner for you. Recent developments in this dynamic market point to the limitless opportunities ahead. Below are three examples of innovation in 3D scanning:3DMakerpro‘s Moose Series 3D Scanner: Committed to bringing users professional and cost-effective 3D scanners, 3DMakerpro, has recently launched the Moose Series 3D Scanner, a device that promises to advance the field of 3D scanning.

Targeted at both novices and seasoned professionals, it uses cutting-edge technology to redefine ease and precision in capturing real-world objects in three dimensions. The Moose Series 3D Scanner scans objects from multiple angles, using laser technology to collect data points that create a detailed mesh representing the object’s surface. It utilizes Blue Light Technology and advanced range cameras to generate lifelike 3D models. Achieving unparalleled precision at 0.03mm and an impressive resolution of 0.07mm, Moose faithfully reproduces scanned objects into vivid, true-to-life 3D models. This process allows for accurately replicating of real-world shapes, textures, and dimensions.

Artec 3D’s medical 3D scanning initiative: Artec 3D, a leading 3D scanning hardware and software developer, has recently partnered with Handicap International, an NGO fostering humanity and inclusion worldwide. Together, they are customizing medical devices for patients in Rwanda. Through this humanitarian project, medical staff received training from Artec experts to use the world’s first wireless 3D scanner, Artec Leo. With a built-in display and battery, Leo ensures greater ease of use in the field. The resulting data allows doctors to tailor orthotics, prosthetics, and supports more effectively, especially in remote areas. Digitally designing these devices also enables cost-efficient 3D printing. The Rwandan team quickly began digitizing anatomies with high accuracy, aiming to create custom orthoses and children’s prosthetics that can be iteratively 3D printed to ‘grow’ with patients.

3D scanning for SFX: LA-based special effects artist Rod Maxwell, known for his work in blockbuster movies, was tasked by a film crew to create head tattoos for characters in an upcoming and highly anticipated new movie. To achieve this, Rod used the Peel 2-S 3D scanner, ZBrush for sculpting and mold making, and Anycubic’s resin 3D printers. The digital workflow allowed him to generate stencils efficiently, even for the character’s stunt doubles. After scanning the actor’s head, Rod projected the original tattoo pattern onto it, extracted and built stencils, and 3D printed them. The iconic head tattoo was airbrushed onto the actor’s head in under 45 minutes. Rod found the learning curve for using the Peel 3D scanner short and is excited to incorporate it into other production workflows.

The examples above illustrate how 3D scanning can open the way to exciting possibilities across a wide variety of industries. R&D tax credits are available to support companies engaged in innovative applications of 3D scanning and 3D printing.

Cimquest

Cimquest is a major integrator and reseller of 3D scanners. Cimquest has locations throughout the nation including New Jersey, Pennsylvania, Massachusetts and Virginia. They were just purchased by Sandvik Group, which will tremendously impact their ability to integrate 3D scanners and other tools and equipment. Sandvik is a manufacturer of premium metal-cutting tools, providing high-end services and machining technology to customers. Beyond metal cutting, Sandvik innovates and collaborates, transforming industry challenges into impactful solutions. Sandvik Group reported about US$12 billion and employed 40,877 people, globally, in 2023.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

In summary, recent developments in 3D scanning have led to exciting innovations across various industries. Notable examples include the Moose Series 3D Scanner by 3DMakerpro, which combines precision and ease of use, Artec 3D’s medical scanning initiative for customized medical devices in Rwanda, and special effects artist Rod Maxwell’s use of the Peel 2-S scanner for creating head tattoos. These advancements highlight the potential of 3D scanning and printing, with R&D tax credits available to support companies pushing the boundaries of technology and creativity.