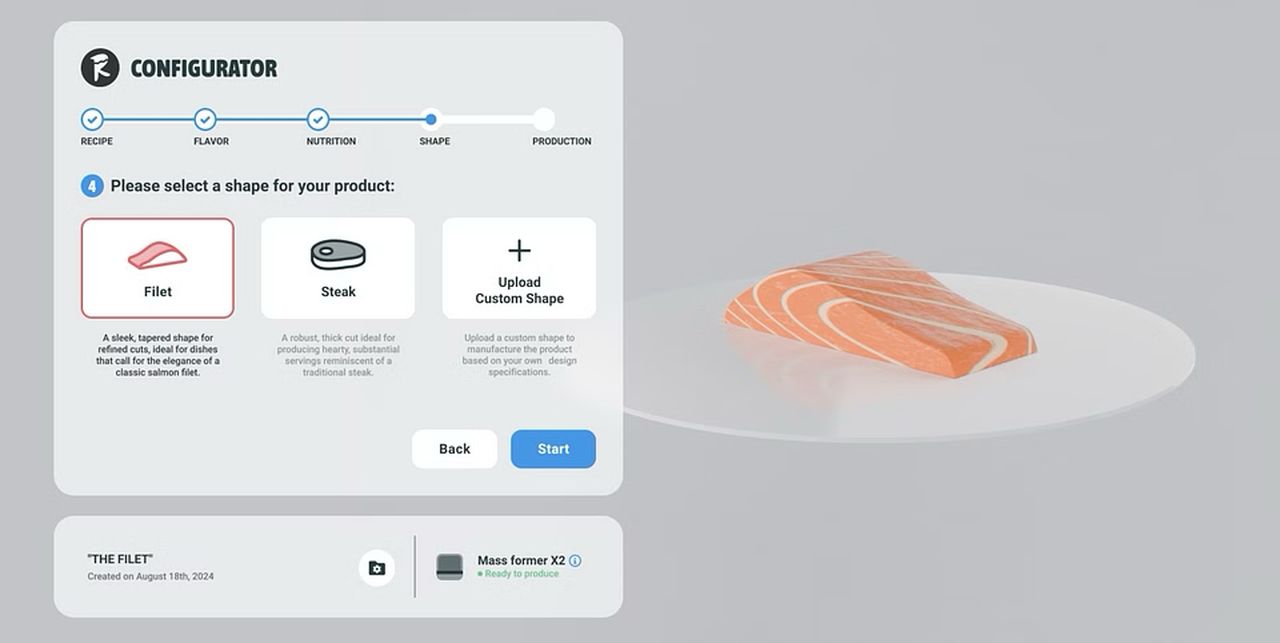

The TASTE FACTORY producing up to 60 tons of 3D printed food each month, starting with THE FILET.

The food industry has been evolving rapidly with the introduction of advanced digital manufacturing technologies. Just last week Steakholder Foods opened up its Demonstration Center in Rehovot. Now, the opening of Revo Foods’ TASTE FACTORY in Vienna shows how 3D food printing is set to revolutionize the way we produce and consume food. Revo Foods, an Austrian FoodTech start-up, has pioneered this industry with its cutting-edge 3D Structuring technology, a milestone that promises to change the landscape of plant-based foods. Its main dish? THE FILET

Revo Foods’ TASTE FACTORY milestone

Founded in 2021, Revo Foods is on a mission to reshape the food industry through its innovative use of 3D printing technology. Specializing in plant-based alternatives, the company aims to tackle some of the pressing challenges in food production, including environmental sustainability, nutritional quality, and the reduction of resource-intensive traditional meat production. The opening of their new facility, the world’s largest 3D food-printing plant, marks a major step forward in achieving these objectives.

3D food printing technology is a form of additive manufacturing, where food is built layer by layer using specialized printers. This technology allows for unprecedented control over the texture, structure, and even nutritional content of food products.

The newly inaugurated TASTE FACTORY in Vienna is the first industrial-scale facility capable of producing up to 60 tons of 3D printed food each month. This production capacity makes it the largest facility of its kind globally. The factory showcases Revo Foods’ ambition to bring plant-based innovations to supermarkets across Europe and beyond, with a focus on high-quality, nutrient-rich, and sustainable food solutions.

The facility utilizes Revo Foods’ proprietary 3D Structuring technology, allowing for the rapid production of foods with complex textures and functional properties. By scaling up production, the TASTE FACTORY can meet the growing consumer demand for sustainable plant-based alternatives.

3D Structuring Technology in the core

At the heart of Revo Foods’ production process is their unique 3D Structuring technology, which combines different materials—such as fats and proteins—to create new food structures that closely mimic the texture of animal-based products. This technology enables the creation of juicy, tender plant-based filets and steaks with an authentic mouthfeel, a breakthrough in the plant-based food sector.

Unlike traditional methods, which rely on high temperatures and pressures that degrade the nutritional quality of food, Revo’s technology works under mild conditions. This preserves the nutritional integrity of the ingredients while creating new culinary possibilities.

One of the main challenges of plant-based foods has been replicating the texture of meat. Consumers want the tenderness and juiciness of real muscle fibers, and this is where Revo Foods’ 3D Structuring technology excels. By precisely integrating fats into a protein matrix, the technology mimics the way fat is distributed in meat, resulting in products that have a flaky, layered texture.

This approach allows for the creation of plant-based filets that fry and bake like real meat. For example, the white fat stripes in THE FILET help separate the layers, enhancing both the mouthfeel and the aroma of the product during cooking.

Read the rest of this story at VoxelMatters