Charles R. Goulding and Kellen Coleman dive into how the bipartisan Ships for America Act and cutting-edge 3D printing technology could restore U.S. shipbuilding leadership and bolster national security.

The Ships for America Act is a bipartisan bill aimed at revitalizing U.S. shipbuilding to address critical gaps in both civilian and naval fleets. Introduced by Representatives John Garamendi (D-CA) and Mike Kelly (R-PA), along with Senators Todd Young (R-IN) and Mark Kelly (D-AZ), the legislation seeks to strengthen America’s economic and national security by increasing the construction of U.S.-built and U.S.-flagged ships.

For decades, the United States has fallen behind in shipbuilding, leading to an overreliance on foreign-built vessels. This decline has weakened the U.S. Merchant Marine, hampered naval readiness, and created vulnerabilities in the supply chain. Meanwhile, adversaries like China have rapidly expanded their shipbuilding capacity, leaving the U.S. at a strategic disadvantage. However, as traditional shipbuilding has stagnated, advances in 3D printing technology have opened new possibilities for ship construction and maintenance. This article explores how the Ships for America Act could help restore U.S. shipbuilding leadership and how emerging 3D printing technologies could play a crucial role in this effort.

The Shrinking U.S. Merchant Fleet

The U.S. Merchant Marine—a fleet of U.S.-flagged commercial vessels essential for military logistics and economic stability—has significantly declined. In 1951, the U.S. had over 1,200 commercial ships in international trade; today, that number has fallen to fewer than 85. This limited fleet means the U.S. is highly dependent on foreign-built and foreign-operated vessels, which could pose severe risks in times of conflict or crisis.

U.S. Navy vs. China’s Naval Expansion

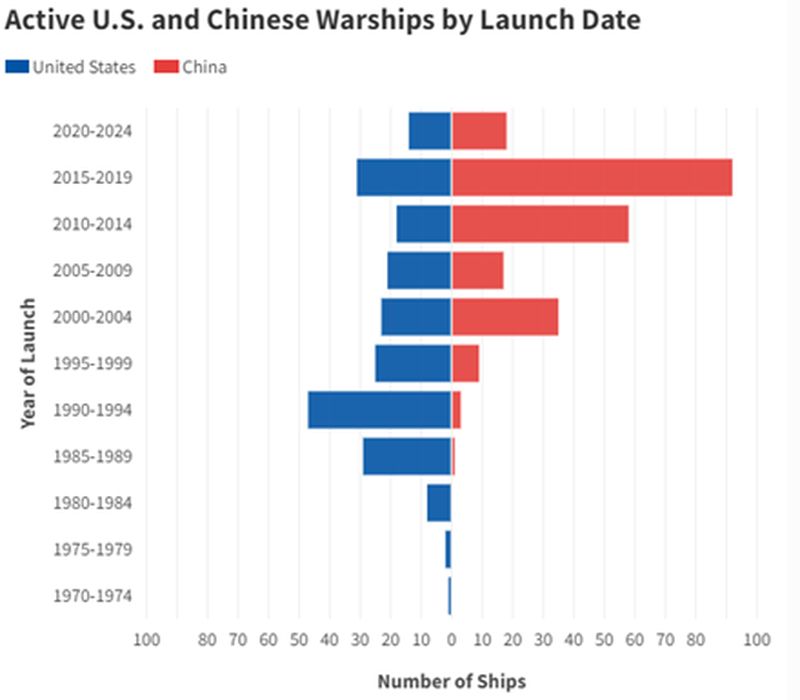

The decline of U.S. shipbuilding isn’t just a commercial problem—it’s also a major national security concern. The U.S. Navy is struggling to keep pace with China’s massive naval expansion. According to the Center for Strategic and International Studies (CSIS):

- China now has the world’s largest navy, with over 370 warships as of 2023.

- The U.S. Navy has around 290 deployable ships far fewer than China’s fleet.

- China is building ships at an unprecedented rate, with projections showing their navy will surpass 400 ships by 2025.

- Meanwhile, the U.S. is facing delays, budget overruns, and workforce shortages in its shipbuilding industry.

A 2024 CBS News report highlighted that the U.S. Navy is struggling to meet its shipbuilding goals, facing supply chain issues and outdated industrial infrastructure. While China can build warships in as little as five years, the U.S. often takes a decade or longer to produce equivalent vessels.

This decline in shipbuilding capacity leaves the U.S. vulnerable in both economic and military terms. The Ships for America Act aims to reverse this trend by incentivizing domestic shipbuilding, expanding government support for American shipyards, and reinforcing the U.S. Merchant Marine.

The Rise of 3D Printing in Shipbuilding

While the U.S. has fallen behind in traditional shipbuilding, there has been significant progress in 3D printing technology for naval applications. 3D printing technology allows for rapid prototyping, on-demand part production, and field repairs, reducing reliance on lengthy supply chains.

One of the most promising developments is the use of 3D printers onboard naval vessels to produce spare parts on demand. Instead of waiting for weeks or months for a replacement part, crews can now print components immediately, keeping ships operational during extended deployments.

A recent U.S. Navy case study demonstrates this capability:

- In late 2023, the USS Somerset (LPD 25), a San Antonio-class amphibious transport dock, successfully used a 3D printer to solve an engineering challenge while deployed.

- The ship’s crew designed and printed a custom tool that was needed for a crucial maintenance operation.

- The ability to print the part onboard eliminated the need for costly delays or supply chain dependencies.

The U.S. Navy’s Expanding 3D Printing Program

The Navy has been actively integrating 3D printing into its fleet and shipyard operations. Two more examples illustrate the growing role of 3D printing technology in naval readiness:

- Submarine Parts Production

- The U.S. Navy has started 3D-printing key submarine components, such as brackets and piping.

- This reduces manufacturing lead times and allows for more efficient repairs during deployments.

- Metal 3D Printing for Warships

- At Naval Sea Systems Command (NAVSEA), engineers have tested metal 3D printing to produce high-strength ship parts.

- This method can create durable components faster and cheaper than traditional casting or machining.

These innovations could play a critical role in modernizing the U.S. fleet, ensuring that ships can stay in service longer and remain combat-ready even in remote regions.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes, and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Fair Winds and Following Seas…

The Ships for America Act represents a crucial step toward rebuilding America’s shipbuilding capabilities. By increasing investment in domestic shipyards, the U.S. can reduce its dependence on foreign-built ships and regain a competitive edge in the global maritime industry.

At the same time, leveraging new technologies like 3D printing could enhance fleet maintenance, reduce costs, and speed up ship production. If the U.S. integrates 3D printing more broadly into naval construction, it could accelerate shipbuilding timelines and reduce the current gap with China’s naval expansion.

The future of American naval and commercial shipbuilding will depend on a combination of policy support, industrial investment, and technological innovation. If the U.S. embraces both traditional shipbuilding revitalization and cutting-edge advancements like 3D printing, it can regain its maritime strength and secure both economic and national security interests for the years ahead.