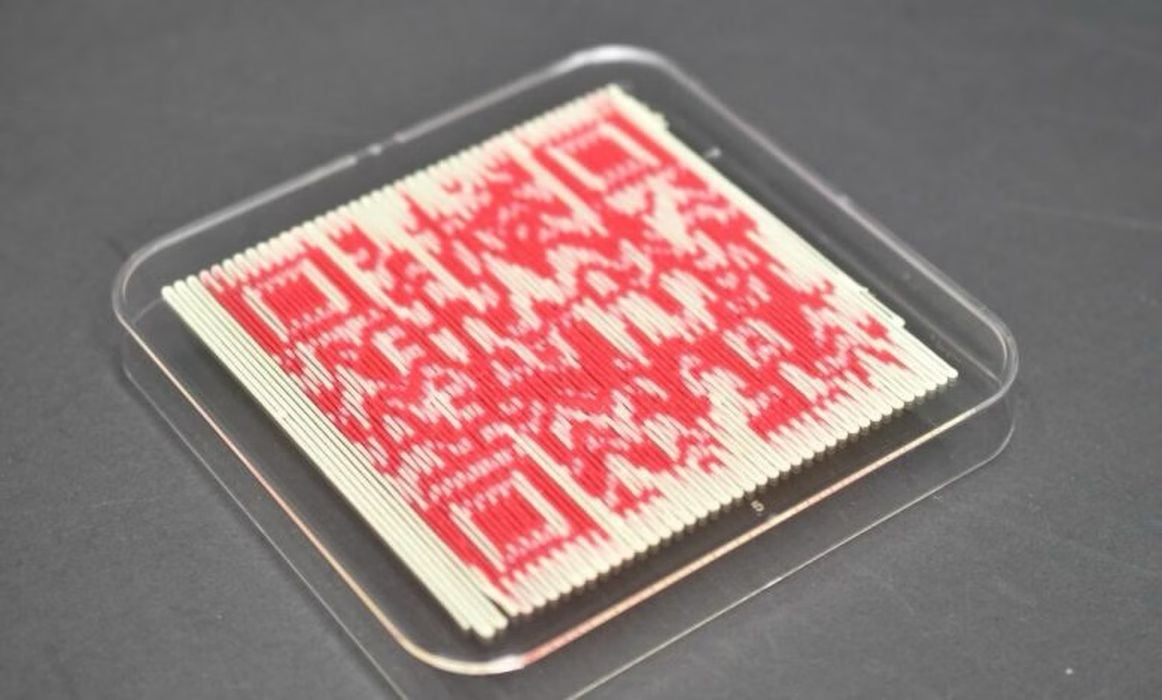

Incorporating edible and nutrient-rich ingredients to construct aesthetically pleasing meals.

According to the Singapore University of Technology and Design (SUTD), a team of researchers has developed new ways to freely produce and customize the food that we eat. Their findings, titled ‘Multi-material direct ink writing 3D food printing using multi-channel nozzle’, have been published in the journal Future Foods.

“Printing food in 3D enables the customization of nutrients, the creation of aesthetically pleasing meals, and the modification of food texture to suit individual dietary needs,” said Michinao Hashimoto, Principal Investigator and an Associate Professor at SUTD.

Some repurposed food sources, such as okara (soybean dregs), orange peels, and insect protein, tend to ward off appetites by their appearances and origins. By adjusting the printing parameters, researchers can incorporate edible and nutrient-rich ingredients from these unusual sources, and construct an aesthetically pleasing meal. At the same time, individuals with eating disorders or who have difficulty swallowing (dysphagic) can customize their mealtime experience and improve their eating habits.

Other researchers have successfully printed foods using chocolate, milk, gelatin, and vegetable inks, but these constructs are largely confined to single ingredients. Existing methods struggle with seamless transitions between materials – leading to fragmented prints and increased complexity in the machine printing process, according to Dr. Lee Cheng Pau, lead researcher of the SUTD study.

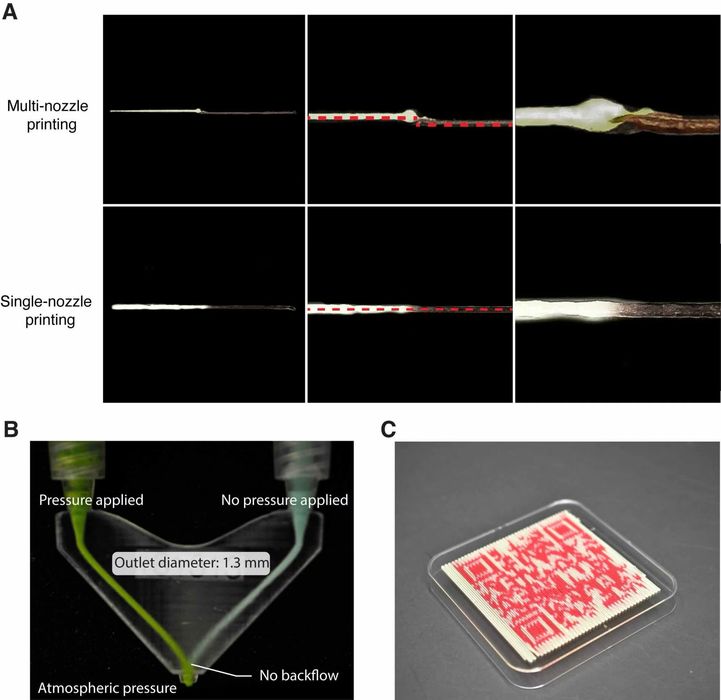

One common approach uses multiple nozzles to hold and eject different food constituents. Requiring careful machine design and nozzle alignment when printing, this approach has discontinuous interfaces where different materials overlap and long printing times. Associate Prof Hashimoto and the team favor a different approach – taking inspiration from microfluidics. With dual inlets and a single outlet, this approach mitigates the intricacies of switching between multiple nozzles by combining the food pipelines before the printing stage.

However, complexities such as backflows into the ingredient inlets tend to happen with fluids of different rheological properties – such as flow and viscosity. For example, squeezing out a dab of toothpaste requires more strength than pouring out water. If the two were to feed into a single outlet, pushing out toothpaste would likely send some paste up into the water inlet.

The first step in overcoming this challenge was to widen the exit outlet of the Y-junction in the printer to accommodate food ingredient inks that are high-yield-stress, which require more force to extrude. This change offers a lower resistance for the flow – preventing the ink from going up the wrong channel in the printer.

In addition to this, it was necessary to account for the delay in the food ink transition. As the location for the switching between inks no longer happens at the printing nozzle, the researchers implemented an offset for the printing algorithm. This enabled seamless and continuous printing between inks with vastly different rheological properties, with minimal backflow. The team hopes to optimize the design and technology further to accommodate more inlets and progress toward commercial scalability.

Read the rest of this story at VoxelMatters