New research shows a method of performing voxelated bioprinting.

Hold on, what does that mean?

Voxelated printing is a somewhat rare capability implemented only in certain 3D printing processes. The idea is to control the specific material by location in the object. Just as a 2D image is made from pixels, a 3D object can be broken down into “voxels”. These building blocks comprise the entire structure.

In conventional 3D printing voxelated processes might enable deposition of a selected material at each voxel in 3D space. This would be important, for example, if 3D printing electrically conductive traces embedded inside an object.

Here the research focuses on a way to control the material by voxel in bioprinting. Previously bioprinting was accomplished with syringe-like extruders that blasted out continuous streams of material, much like a multi-head FFF 3D printer.

That is useful, but in the future bioprinting will become far more complex and require the ability to control the prints much more directly. Imagine a distant future where an advanced bioprinter is printing a human organ. That organ would require very precise positioning of many different materials to construct the necessary functional elements. That’s only possible if you have voxelated bioprinting.

The researchers have developed a process to do so they call Digital Assembly of Spherical Particles (DASP). This technique allows for the precise placement and integration of hydrogel droplets, which can be made from combinations of materials such as polyacrylamide and alginate, both popular in bioprinting due to their structural properties and biocompatibility.

They developed hydrogel formulations with enhanced mechanical properties using interpenetrating networks of alginate and polyacrylamide. These materials are crosslinked through a click chemistry approach, free from additives, making them more biocompatible and robust for medical applications.

In order to print these materials, they also developed a new multi-channel nozzle system to deposit the materials, which allow for on-demand mixing of bio-inks.

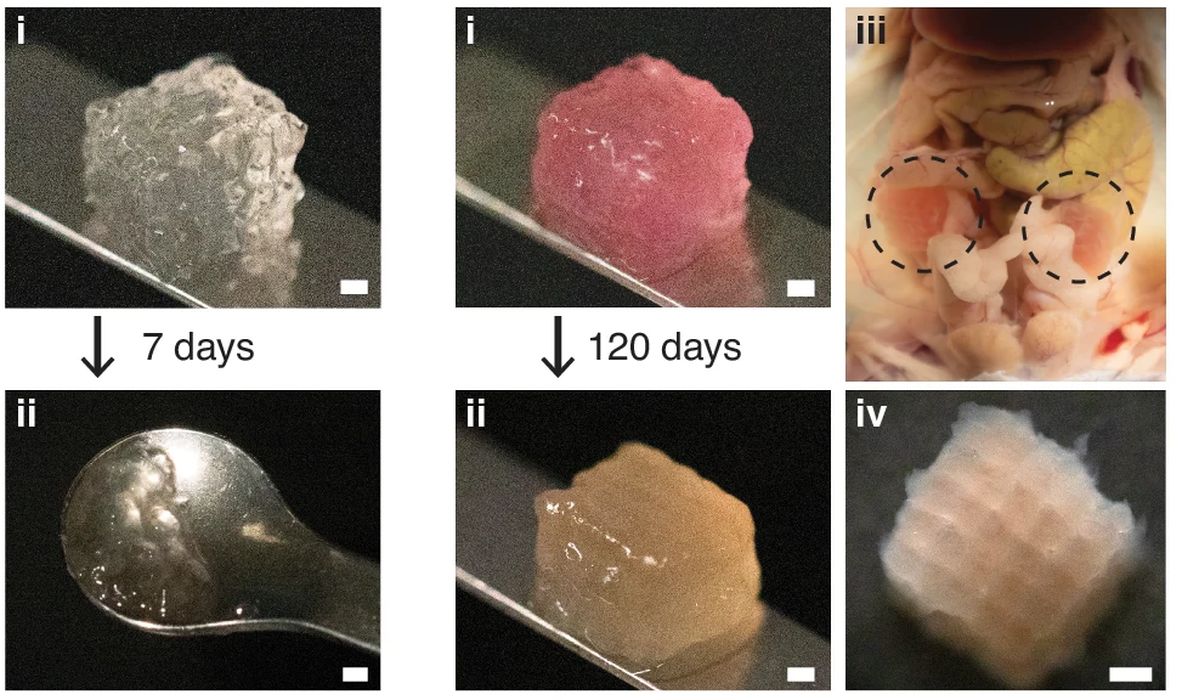

Subsequent tests of the resulting prints revealed both biocompatibility and structural integrity: they printed cells that were able to maintain integrity when exposed to typical physiological conditions.

This sounds very promising, as it could open up many possibilities for future research into 3D printing of more complex bio structures, perhaps eventually leading to human organs.

Via Nature