Researchers have found a way to predict the bonding of supersonic metal particles.

Metal 3D printing has several methods, including laser bed powder fusion, wire arc additive manufacturing, binder jet, and more. One rare approach, used only by SPEE3D, is supersonic 3D printing.

The idea is to blast metal particles at extraordinarily high speeds towards a target. The particles impact the target with great energy, but the force pushes the particles so close together that they naturally bond at a molecular level. There’s no heat involved; it’s just that the particles are so close that they literally become part of the metal object.

This process has been understood by science for some time, and SPEE3D has implemented the concept in 3D printer form.

However, the researchers were not so concerned with how it works but how well it works. What strength of the resulting metal bonding can be expected? What factors vary the bonding strength?

They decided to investigate the phenomenon at a micro scale, explaining:

“The bottom-up approach presented here is different from the measurements of mechanical properties at the deposit level, which involves hundreds of thousands of deformed particles, each with unique and distinct kinetic and thermal histories. Consequently, breaking beyond the average-based correlations between impact parameters (e.g., particle size, temperature, velocity, and impact geometry) and bulk properties to uncover the fundamental origins of property development proves highly challenging.

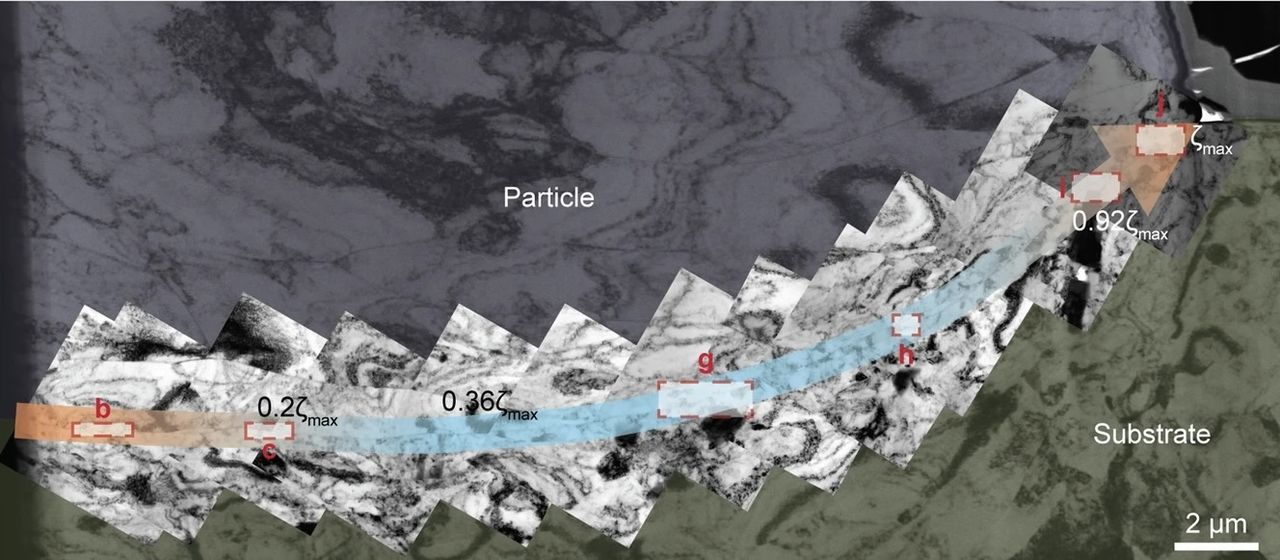

In contrast, we isolate individual interfaces produced by the impact bonding of individual particles with precisely measured or controlled kinetic, thermal, and geometrical parameters to study interfacial strength. We release the assumption of uniform properties that is implicit in the deposit level measurements and reveal that a significant variation in bond strength exists within one single interface.”

Incredibly, they used micro-machining tools to prepare test coupons for testing tensile strength. They tested many samples that had varying properties.

What did they find? They explain:

”We revealed a significant gradient of bond strength across impact-induced bonded interfaces. We observed relatively low bond strength in regions near the impact center, followed by a sharp twofold increase to a peak that is significantly higher than the yield strength of the bulk material and, ultimately, a plateau covering over 60% of the interface towards the periphery.”

and:

“With high-resolution transmission electron microscopy, we showed that the form of the native oxide residue at the bonded interface (i.e., layers, particles, or debris) dictates the level of bond strength.”

They also developed a predictive framework for estimating the strength of bonding when given the operating parameters.

That should be of considerable interest to SPEE3D and any other company developing a supersonic-based 3D printer.

Via Nature