Researchers have developed a method of visually indicating strain on 3D-printed parts.

This approach could enable a new range of 3D-printed applications, but how exactly does this work?

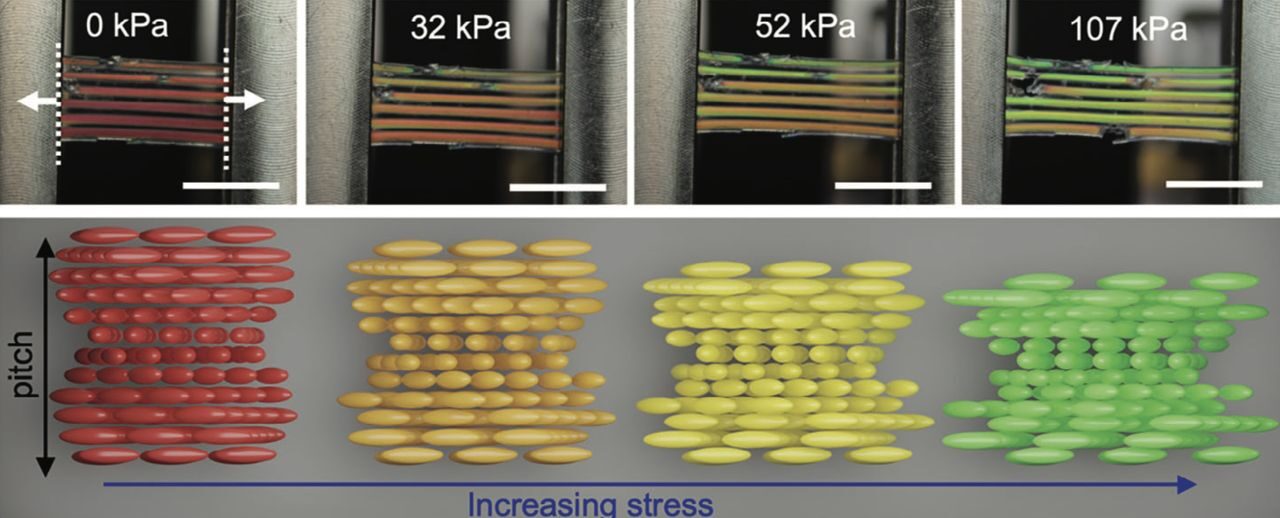

It’s all based on something called “Cholesteric Liquid Crystal Elastomers” (CLCEs), which respond to stress by changing color due to their helical molecular structure. If you bend them, they change color!

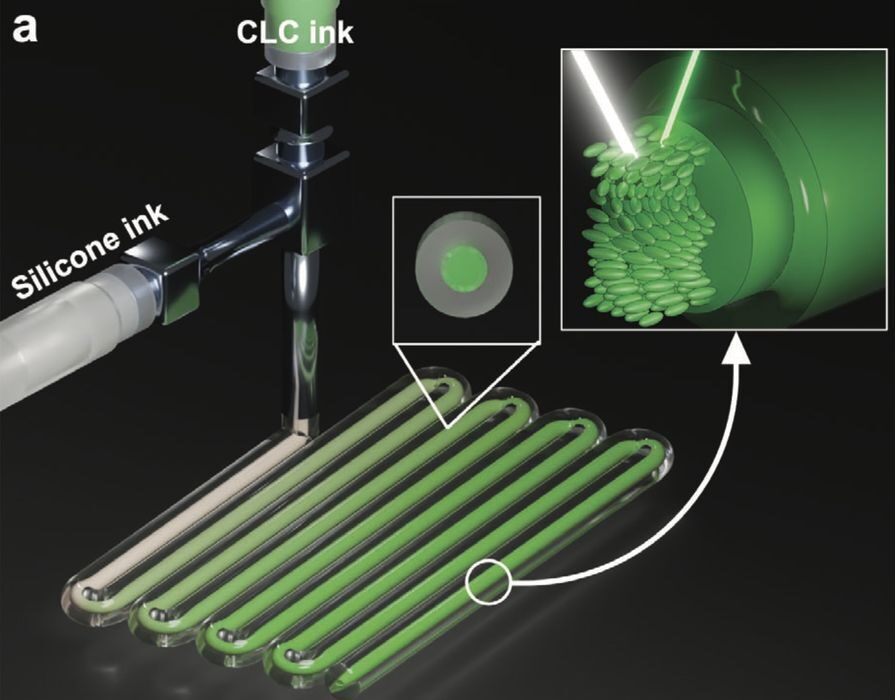

The researchers were able to construct a specialized 3D printer to make use of CLCE properties. The printer’s toolhead was coaxial in design: the inner core extrudes CLCEs, while it is surrounded by a sheath of silicone. Basically, the machine extrudes tubes of silicone with the color-changing material inside.

The silicone also enhances visibility of the color, much like glass would do in a thermometer.

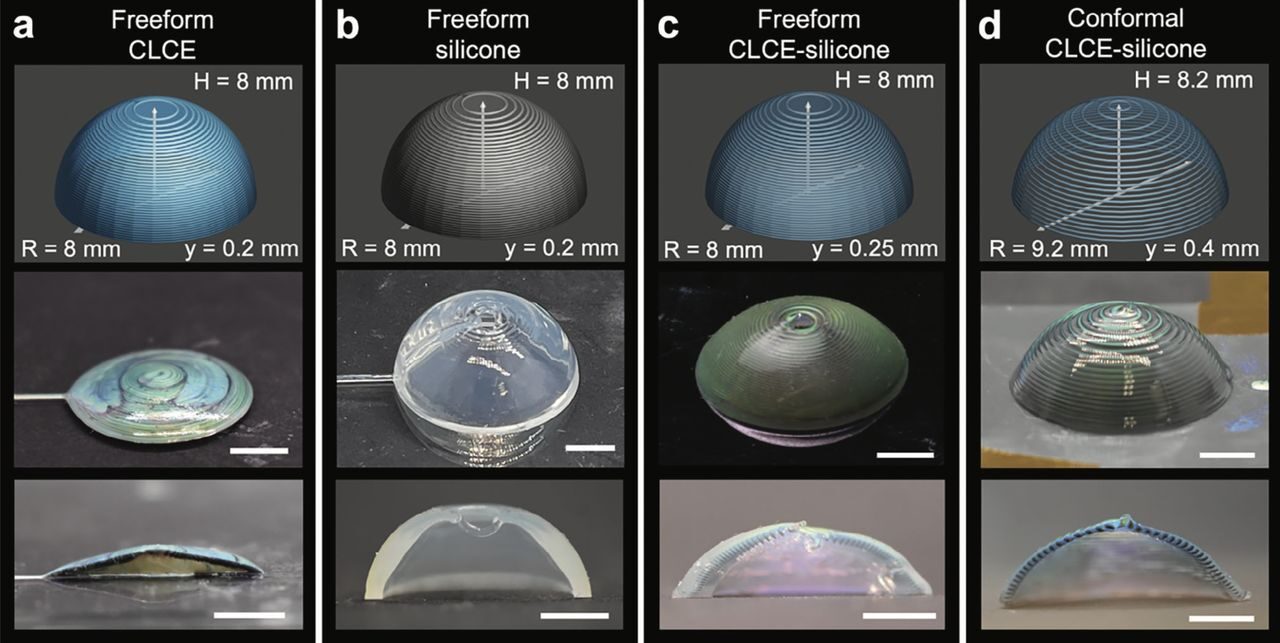

The researchers printed “domes” with this material, which would react when undergoing stress. These structures can store stress states, effectively giving them physical memory, and arrays of these domes act as mechanochromic strain sensors with memory.

There are countless possible applications for this technology. One might be “smart labels” that are applied to packages. These could indicate tampering, and could even be integrated into QR codes. Imagine if the QR code could change depending on stress affecting the object.

Garments could incorporate the technology to show stress areas. This could be useful in medical or physiotherapy situations, particularly in educational settings.

The memory effect could be used to record physical events, like footsteps or touches. There could be interesting security applications here.

Finally, this technology could also be used for unimaginable kinetic art displays.

CLCE technology could be extremely interesting as it enables a wide range of 3D-printed smart applications.