A new technique could supercharge volumetric 3D printing processes.

If you’re not familiar with volumetric 3D printing, you should know that it is by far the fastest method to print objects. Instead of waiting for hours for a print to complete, volumetric approaches can complete objects in only seconds or minutes.

How is this done? It’s really quite an ingenious twist on the resin 3D printing process. Normally resin 3D printers produce layers sequentially, stacked on top of each other. This can take considerable time because there are a number of movements required between layers.

A volumetric approach is different. Instead of printing layer by layer, the entire object is formed simultaneously.

This is done by rotating a cylinder of transparent photopolymer resin while a projector blasts 2D images into the cylinder. The images are organized so that energy accumulates at spots where solid material is required. When a sufficient amount of energy is gathered at a point, the photopolymer reaction triggers.

Another way to look at volumetric approaches is to think of it as a “reverse CT scan”. A CT scan will capture 2D images “through” a patient from all angles, which are then reconstructed with software to produce a 3D model of the inside of the subject.

In contrast, the volumetric approach starts with the 3D model and breaks it down into the very 2D images that would be projected into the rotating cylinder.

This can work very well, although there are some challenges with the materials: the requirement for transparency severely limits the material types, and the maximum build size is small due to the requirement for energy to penetrate deep into the resin.

There has been an interesting development, however. Researchers were concerned with the limitations of 2D light projections, as it is challenging to achieve optimal accuracy: imagine trying to figure out the collection of 2D projections that would lead to the correct 3D model.

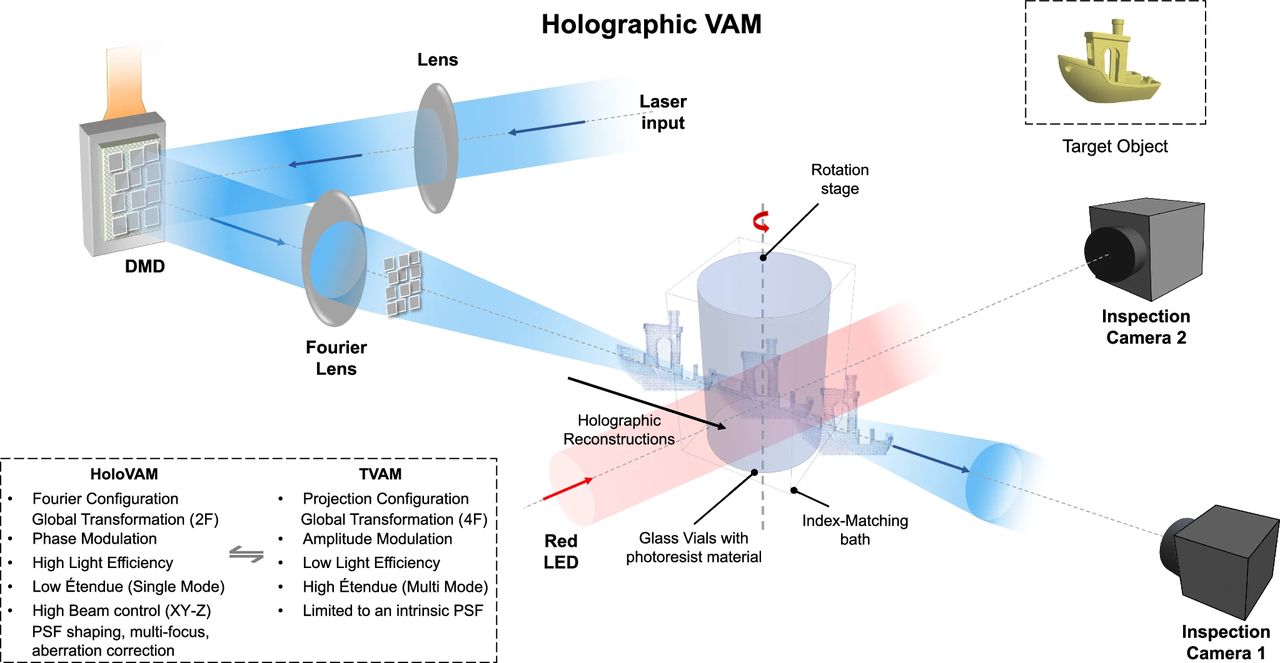

Their new approach is to replace the 2D projector system with a hologram.

A hologram is a method of producing 3D images by leveraging optical interference patterns. The light field is truly 3D, and if you’ve seen one you know that you can walk around the field and “see” the projection as if it is a real 3D object.

The researchers believed that they could improve volumetric 3D printing by using a 3D image produced by a holographic approach to delivery energy to the resin. Their design is called “HoloVAM”, and they identified two major advantages over traditional VAM:

- Light efficiency is improved as all pixels contribute to the 3D image pattern

- There is an ability to perform digital control over the 3D light pattern

How efficient is HoloVAM? They explain:

“We demonstrate a printing time of less than 60 s with a single continuous-wave 40 mW laser diode at 405 nm (coupled with an efficiency of 33% in a single mode fiber) and reach negative features (holes) of 31.35 μm reliably. This short printing time is the result of the efficiency of the light engine.”

In practice, they were able to 3D print a #3DBenchy with 28.6X less energy than VAM methods, which is quite significant. In fact, all of the parts produced by the research team were printed in less than sixty seconds each.

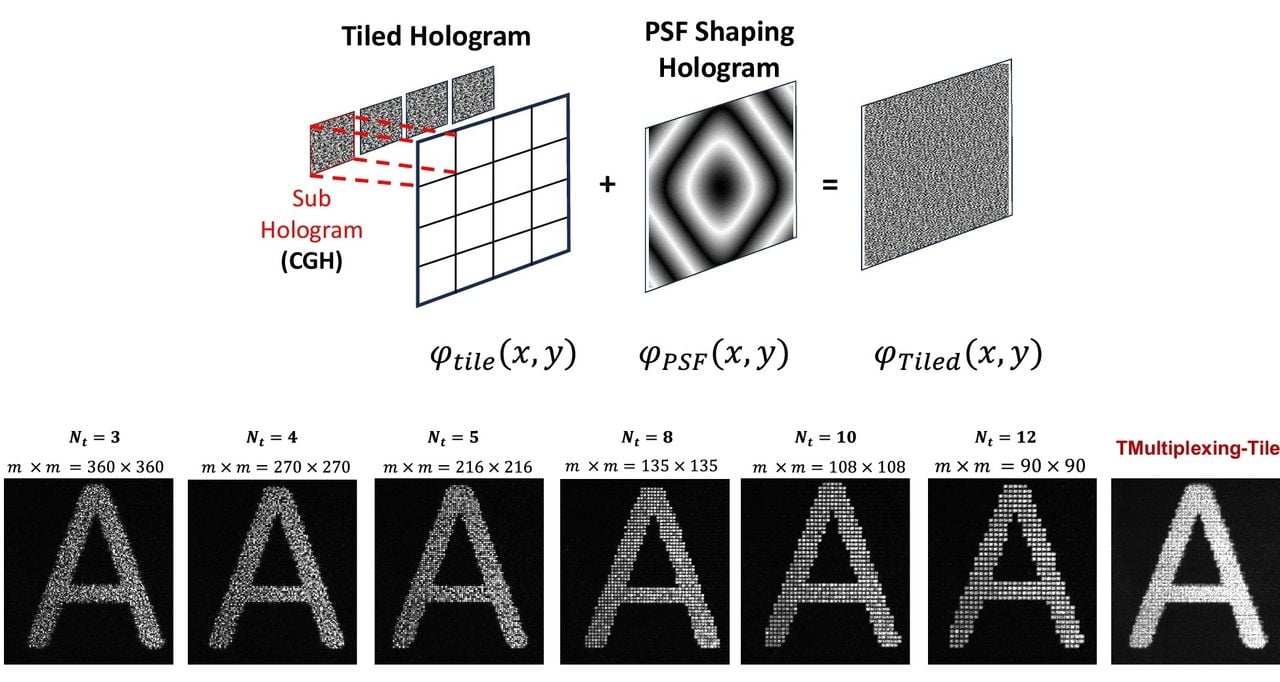

An interesting aspect of HoloVAM is that it uses a “tiled” approach. They generate a series of “sub holograms”, which are adjacent to each other. This approach reduces the “speckle” effect that can corrupt the process.

This new approach could lower the cost of volumetric 3D printing as less expensive light engines could be used. However, the technique still suffers from build volume limitations.

Via Nature