Researchers have developed a method to 3D print a whole-body artificial skin for humanoid robots.

That’s a bit of a mouthful, so let’s dissect what’s happening here.

The rise of humanoid robots is now inevitable. Multiple companies have been designing this type of device, with the intention of using AI programming to enable them to do all types of work. Humanoid robots are desirable because they can automatically fit into equipment and furniture designed for actual humans without any change.

However, these humanoid robots are made of metal and plastic, quite unlike the science fiction vision of humanoid robots that is often indistinguishable from real humans.

The difference could be bridged if these humanoid robots sported proper skins that would become the visible layer. That would require the production of human-like skin, equipped with appropriate sensors and other elements. But how do you make such a thing?

3D printing, that’s how. The researchers developed something they call the GenTact Toolbox. They explain:

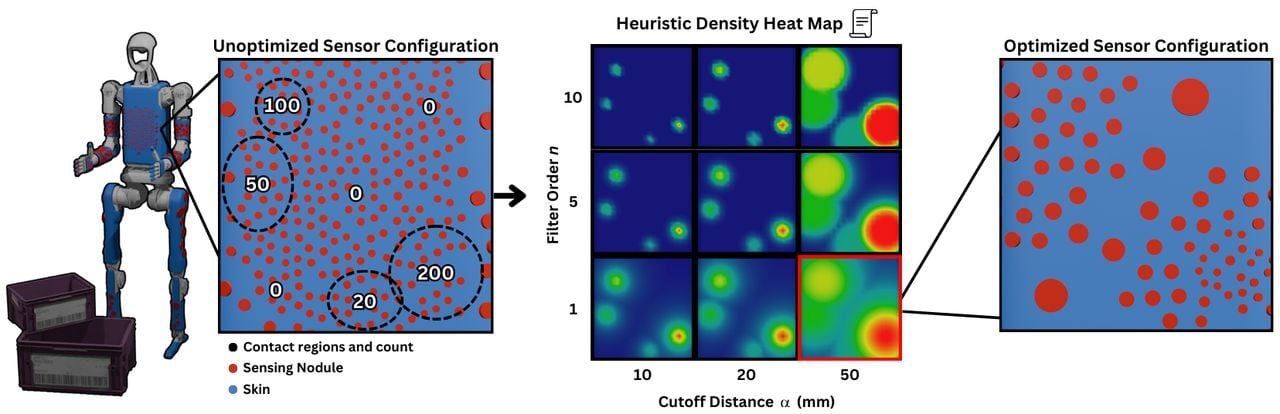

“We introduce GenTact Toolbox, a computational pipeline for creating versatile whole-body tactile skins tailored to both robot shape and application domain. Our method includes procedural mesh generation for conforming to a robot’s topology, task-driven simulation to refine sensor distribution, and multi-material 3D printing for shape-agnostic fabrication.”

Their work was tested using a robotic arm. The arm was fitted with a skin that included six different types of sensors, all 3D printed.

This work is important because it provides a means to generate 3D printable models of robotic skin in a wide range of scenarios. This could make future robots not only more lifelike, but also more functional and adaptable to different situations.

Via ArXiv