Researchers have developed a way to 3D print variable height layers in aluminum using WAAM.

WAAM, or wire arc additive manufacturing, is a popular 3D print process involving a toolhead that extrudes standard welding wire into an electrical arc. The energy instantly melts the metal wire, which then can be deposited in a controlled manner by mounting the toolhead on a robotic arm.

The process has been implemented in a number of different products, but all suffer from poor quality output: the depositions tend to have thick, coarse-looking layers. This often requires the use of post-processing techniques to smooth surfaces.

An alternative approach to post-processing is to print the object with smaller layers. This is commonly done in FFF 3D printing, and many FFF slicing tools include this feature.

For metal 3D printing, it’s a bit different. The variable layer height approach has been successfully used with steel deposition, but it has not been achieved with aluminum metal.

That’s because aluminum printing is quite tricky. Proper depositions require extraordinarily precise control over movement, feed speed, and temperatures. If a layer height change is attempted, these factors are messed up, and problems ensue.

This problem has now been solved. Researchers devised a system that can print variable height layers in aluminum using WAAM.

How was this done?

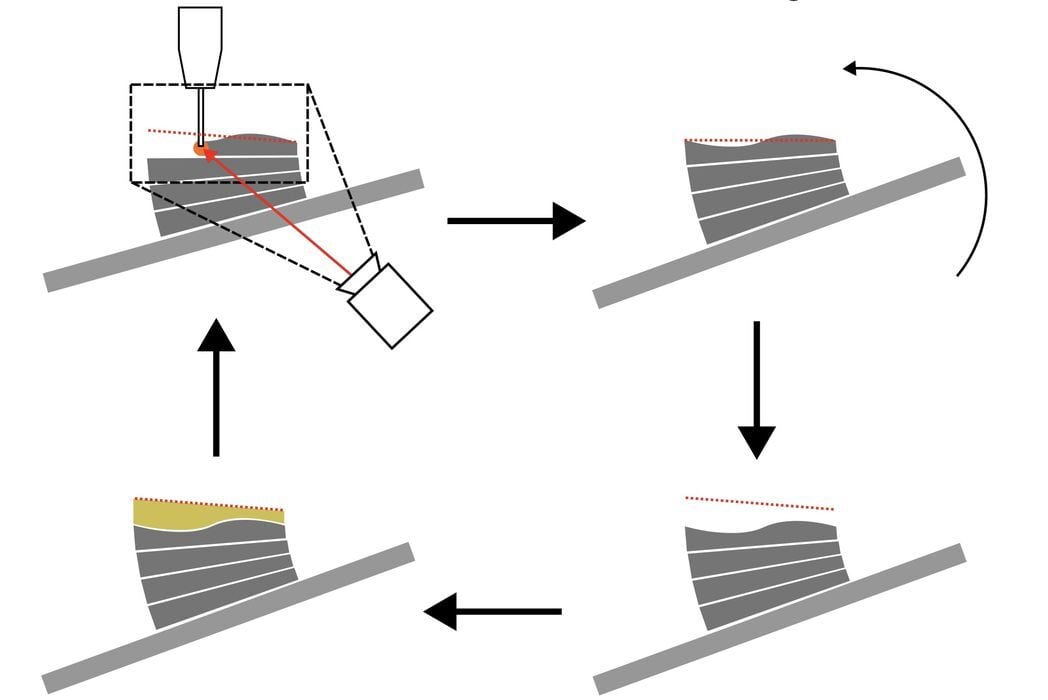

Their approach was to measure layer heights with an IR camera and update the robot’s motion in real-time. A process model was developed to model deposited height as a function of torch speed and temperature. They also established velocity bounds to ensure consistent welding.

In operation, the system applies a “correction framework”, which compares actual and target height in real-time. The software adjusts torch speed layer-by-layer, using Quadratic Programming to optimize speed changes.

This sounds complicated, and it is. But that’s what you need to do in order to keep the aluminum printing properly.

I’m wondering if this technique could be applied to other commonly printed metals to improve the quality of the output.

Via ArXiv (PDF)