After our story about increasing concerns about 3D printer waste, the question becomes, “what should I do about it?”

This is all triggered by Bambu Lab’s innovative four-color switching system, the AMS. It has been so successful we’ve seen multiple other players introduce very similar filament switching accessories. These are easy to add to a single hot end FFF 3D printer, and not having that option might dampen sales. We’re likely to see several more appear in the next few months, and it eventually could become a de facto standard expected by buyers.

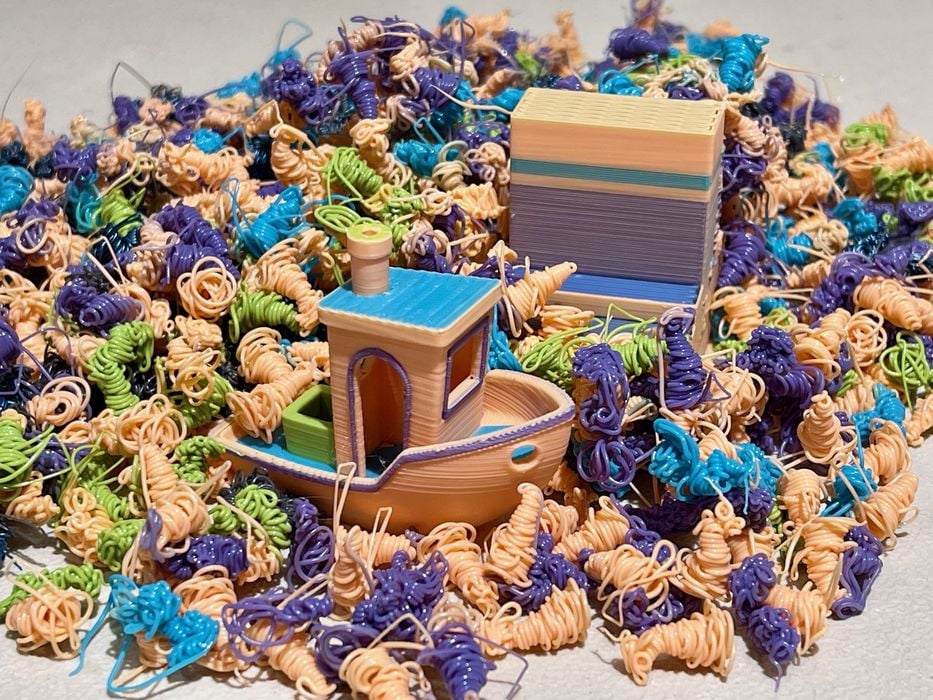

The problem is that the Bambu Lab concept involves “poop”. During a filament swap, the filament is literally cut before being retracted. This allows the machine to cleanly purge the old material, resulting in a “poop” that is ejected.

Depending on the number of color swaps, a given print job could generate a huge amount of poop. In some cases there is more poop than model, and those situations are bringing environmental attention to the practice of 3D printer pooping.

If you have one of these machines, is there anything you can do to help reduce the poop problem? By doing so you not only help with future microplastic pollution, but also save money because you consume less filament. There are several things you can do.

Standard printing profiles make no assumptions about your print, so it’s possible to play around with things to optimize poop production.

Purge to Infill or Support

It’s possible in the slicing software to have purge material printed in the throwaway supports or infill on the model. This reduces waste somewhat but the results depend on the specific model being printed. It’s also possible that some infill purge material might be visible through the exterior of the print.

Flush Tuning

The goal of the purge is to ensure there’s a clean transition of color from one to the next filament. The slicer makes very conservative assumptions about the amount of material required to achieve “clean”. However, the actual required purge amount varies from material to material. A to B may require more purge than B to C, or C to A, for example.

It’s possible to tune the purge amounts in the slicer. You would have to do some experiments to determine the precise amounts by testing all four filaments against each other. That’s a lot of work, but can reduce the amount of purge somewhat.

One innovative Bambu Lab operator found a way to reduce poop by introducing a significant retraction before cutting the filament. This was noticed by Bambu Lab and directly incorporated into the machines and software. For other machines it’s likely there are similar approaches possible.

Multiple Copies

This doesn’t always work, but if you print multiple copies of an object the number of swaps is reduced. That’s because on a given layer all of each material will be printed. For example, if a job takes 47 swaps when printing one item, it will also take 47 swaps to print a dozen in the same print job.

Reorientation

Swaps happen within layers, so the best orientation would be one that “flattens” each color zone as much as possible. The worst and most pathological poop-generating print would be a tower with all colors present on each layer.

Do the opposite, or as best you can orient the print.

Print Second Object

Some prints require multiple colors, and some don’t. If you’re printing a doorstop or soap dish, does it really matter what color it is?

Here the plan is to print the colored object, but add a second color-agnostic object. Then set the print parameters to purge into the second object but not the first one. This should reduce poop considerably.

Split the Model

If your object has very simple color geometry, then consider chopping it up into smaller parts that can be assembled later. These parts would print without (or have fewer) swaps, reducing poop.

Shrink Prime Tower

Most of these color changing 3D printers use not only poop but ALSO a prime tower in each job. The prime tower is basically poop but in another shape, and serves to help purge out more material. In theory there shouldn’t be a prime tower if the poop purge is sufficient.

One approach would be to perfectly tune your purge amounts, and then turn off prime tower. Another approach could be to reduce the size of the prime tower, if that’s possible in the slicer.

Changing Color Selections

Some designers create multicolor objects without regard to the poop implications. For those you might consider changing some of the colors. Do you really need that one dot of pink? Could it be the another color that’s already swapped in? Take a close look at the color arrangement and see if it’s possible to change colors that don’t significantly affect the visual appearance.

Painting

The only way to completely eliminate poop is to not poop, and that’s done by printing in a single color. But how do you get a colored model then? You’d have to resort to the old-fashioned way: painting.

More work, yes, but you have an infinite choice of colors!

If There’s Still Poop

Even if you implement most of the above strategies, you will probably still have some poop to deal with. You could toss it out as most people do, but there is another possibility: recycling.

The easiest way to do so is to pour the poop into a rectangular mold and put it under a heat press. The plastic melts and forms into a multicolored sheet, which can be used in other projects.