A company is using Bambu Lab equipment to produce on-demand products at retail locations.

Red Wolf technology focuses on creating on-demand solutions for retail operations, mainly directed at telephony services. They provide three current services, according to their website:

- Primo Polish, a desktop system to polish scratched smartphone screens

- Primo Protect, a desktop machine that custom-cuts screen protectors on demand

- Primo Print3D, a system for retailers to 3D print a variety of items on demand

The latter product is of interest to us.

It’s primarily used today for printing phone cases on demand. They explain:

“With significant improvements in 3D printing quality over the past few years, we can achieve levels of precision and detail that were once thought impossible. Our team has extensively tested various widths, materials, and surface finishes to perfect our printing process, ensuring that each phone case we produce is of the highest quality.”

The 3D printer they’re using for Primo Print3D is the popular Bambu Lab P1S device, with an AMS attached to enable printing of multiple materials. That’s ideal for printing phone cases, and Red Wolf said they can produce items for the customer in only 30-60 minutes.

They emphasize to the retailer that they will “never run out of inventory”, as it’s all digital.

This is the digital inventory concept, except implemented in a retail setting.

While the current use of Primo Print3D is for the on demand production of phone cases, Red Wolf intends the platform to be used to also print a variety of other items.

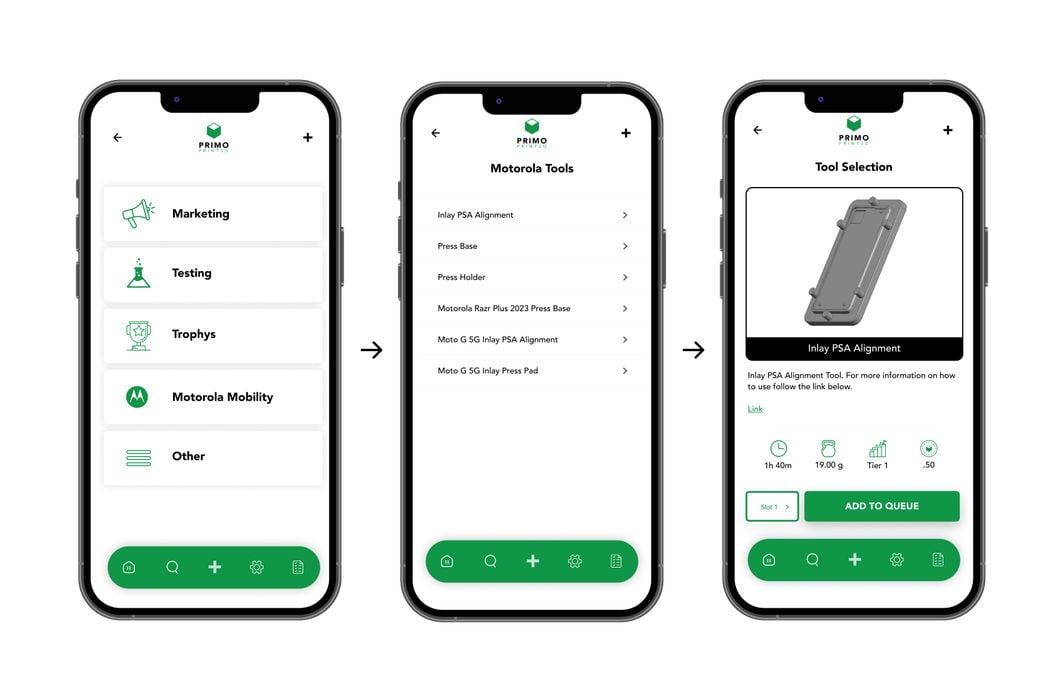

One of them has just been announced: they’ve partnered with Motorola to allow phone shops to 3D print “genuine OEM Motorola tools” that can be used to repair Motorola and other mobile devices. These tools can be, for example, jigs that hold parts aligned when re-assembling parts. Above you can see the app used to select and print the Motorola tools.

This is a very interesting application: making tools, jigs and fixtures for repair shops on demand. I am pretty sure this hasn’t been done on this scale previously, but it is a use case that clearly makes sense.

Repair shops can quickly produce the tools they need to do the job, eliminating delays. It’s also possible for new tool designs to be immediately dispatched to wherever they’re needed. Should a new smartphone appear on the market, the tools for it can be instantly ready for repairs at any Primo Print3D location.

Why hasn’t this been done previously? There have been 3D printers around for eons, but the issue has been speed, ease of use and reliability. Anyone investigating the idea of retail 3D printing in the past decade would have realized it would not work for those reasons.

What changed? It seems that Bambu Lab’s emergence on the scene with a relatively inexpensive machine that is easy to operate, produces very high quality output and at far faster speeds changed the game.

We in the 3D print world see that technology changing our space, with numerous new high speed machines now emerging. But for entrepreneurs the new capabilities open up business opportunities that previously were closed.

It’s time to open for business. What other applications are enabled by high speed, reliable 3D printing?

Via Red Wolf