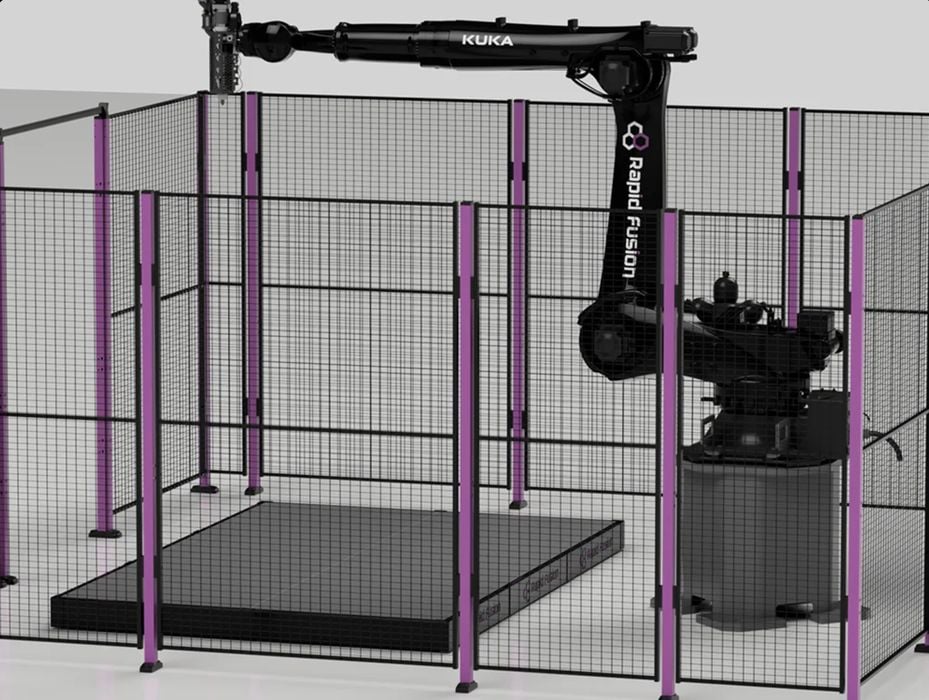

Based on a custom control system and Kuka robotic arm, Apollo system retails for £250,000.

Rapid Fusion, a sister business of 3D printing hardware specialist EVO 3D, is aiming to become a major player in additive manufacturing platforms designed, built and assembled in the United Kingdom.

The company claims it has invested more than £500,000 into bringing its latest product, dubbed “Apollo” to market. The large-format 3D printer is designed to be a full turnkey additive manufacturing solution that utilises robotics to support the production of large components and moulds.

Founder Jake Hand believes this new technology will help automotive, aerospace and furniture manufacturers achieve high quality builds at rapid speeds and at a fraction of the cost of other models.

According to a press release, the company expects more than £4m worth of sales in the first year. “I’ve been involved in the sector for some time and companies were continually asking for a product that offered them an automated large format solution,” said Hand.

“Nobody was doing anything like this in the UK, so we thought…you know what, let’s see what we can do, and our Apollo system represents a massive innovation that promises to disrupt the status quo.”

Hand describes Apollo as utilising a, “world-class, award-winning pellet extruder, tailored control system and robotic Kuka arm that extends to nearly 4 metres. …users can design and produce products on a print bed that is 2 metres x 3 metres squared, ideal for creating bespoke furniture pieces, large auto parts and complex aerospace components.”

Apollo, which retails at £250,000, is the first bespoke cell the company is bringing to market. Rapid Fusion claims it offers faster speeds than FDM printers (nearly 200 times quicker), as well as the ability to use hundreds of different engineering-grades polymers and custom composites.

The company also states that its clients have the potential to secure significant cost savings, with pellets costing 65% to 90% less than filament of the same plastic.

Read the rest of this story at ENGINEERING.com