I’ve just run across an incredible online resource for those designing 3D printed parts.

This past week, a massive post appeared on Rahix’ blog with an astoundingly detailed tutorial on design for manufacturing using FFF 3D printing. Rahix explains:

“Over the past years, I have gotten deeper and deeper into 3D printing. One thing that fascinates me a lot is how different it is from other manufacturing methods. And how this, in turn, means a completely different design philosophy is needed to create good designs for 3D printing.

As such, I have been collecting the little tricks and rules for designing well-printable parts. And of course, I am always on the hunt for more. In this blog post, I want to share all that I have learned.”

And that’s precisely what they do in the almost 14,000-word post.

The post covers a wide range of design techniques for 3D printed parts, including:

- Part strength techniques

- Manufacturing tolerances

- Part finish

- Process optimization

- Functional integration

- Machine elements

- Appearance

- Vase mode

There are dozens of useful techniques presented, any of which may be critical to a project. Here are some examples of what you’ll find in this amazing document:

- Using Shadow Lines to hide seams

- Techniques for strengthening threaded holes

- When to really use fillets or chamfers

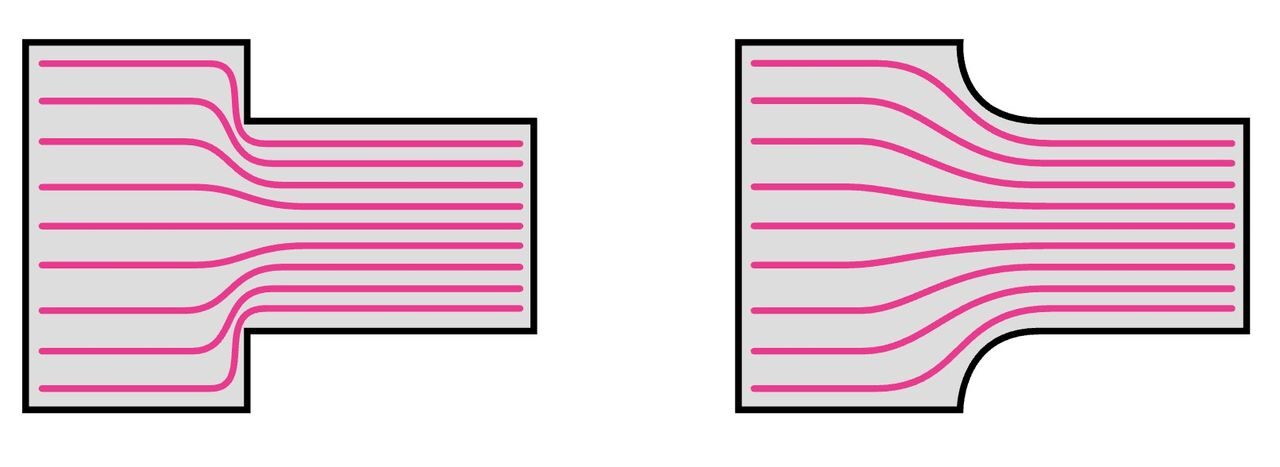

- Increasing strength by modifying lines of force

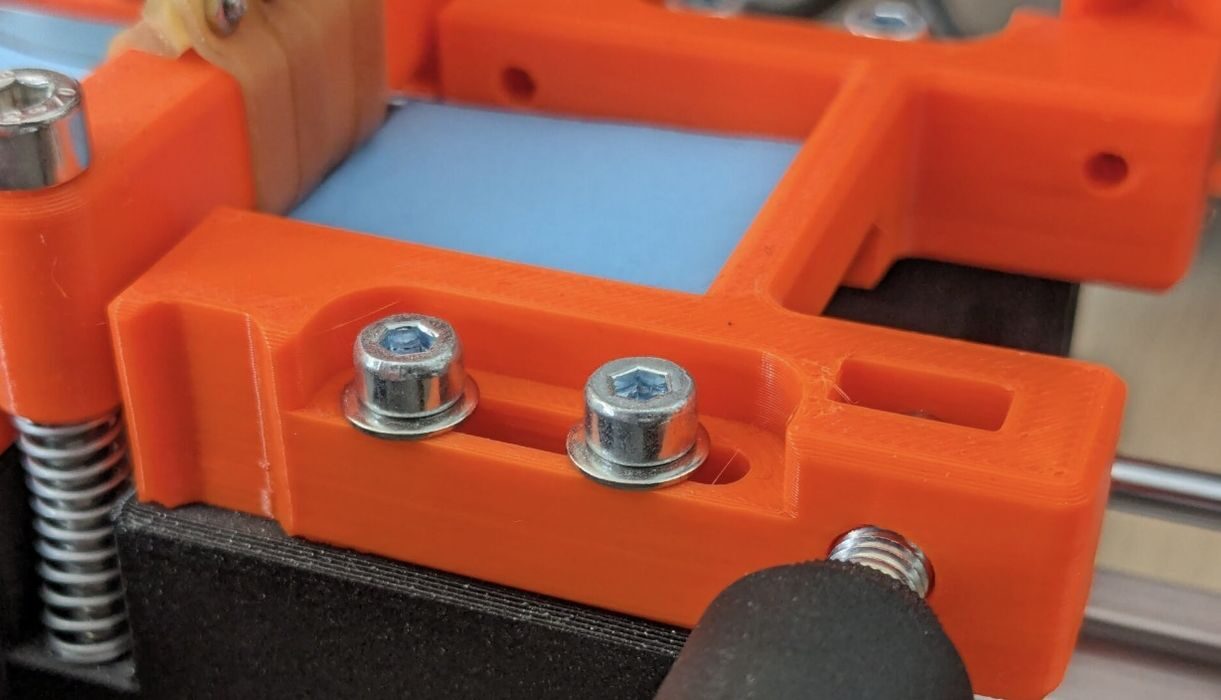

- Using crush ribs to hold insertions

- How mouse ears can hold down pathological first layers

And countless more.

While I was aware of some of these methods, I was surprised to learn many I had never considered. Some will be useful only if you are designing certain types of features, but absolutely, there are tips for everyone in this long post.

The tips are all aligned towards three main objectives:

- Design according to force — Parts should be designed such that their geometry is optimal for the forces it has to transmit and withstand.

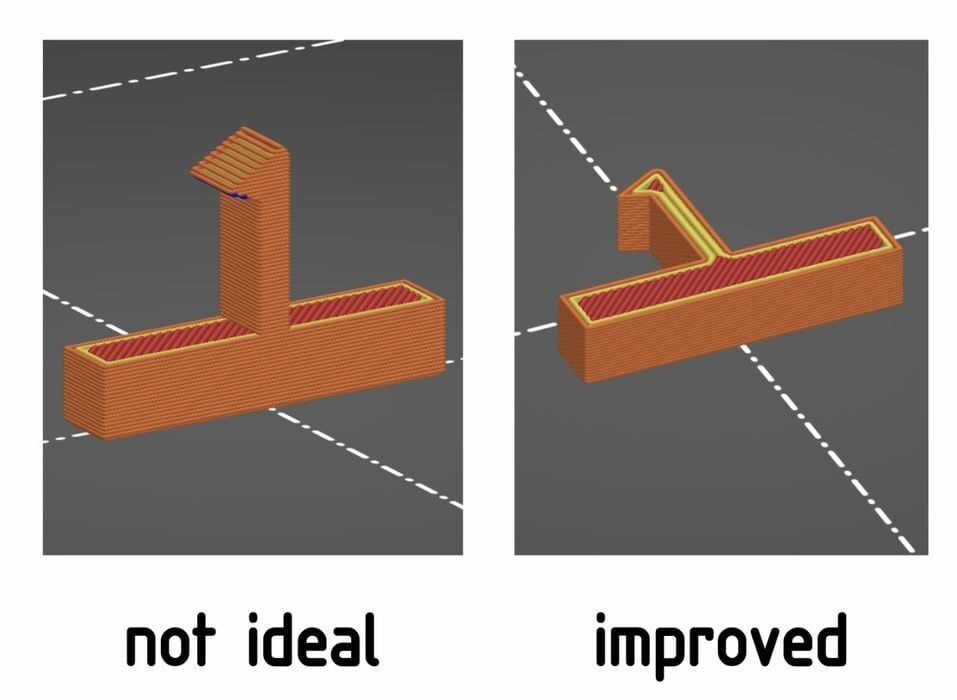

- Design according to manufacturing method — Often called DFM (Design For Manufacturing), parts should be designed such that they are easy to produce. Little changes, which usually don’t affect functionality, can often make a part much simpler to manufacture.

- Design according to cost — Parts should be as cheap as possible. With 3D-printing, this means minimizing material use and print time.

If you’re doing any kind of part design for FFF 3D printing, it should be mandatory that you read this entire post from top to bottom. You will learn many design approaches that will improve your prints.

Via Rahix