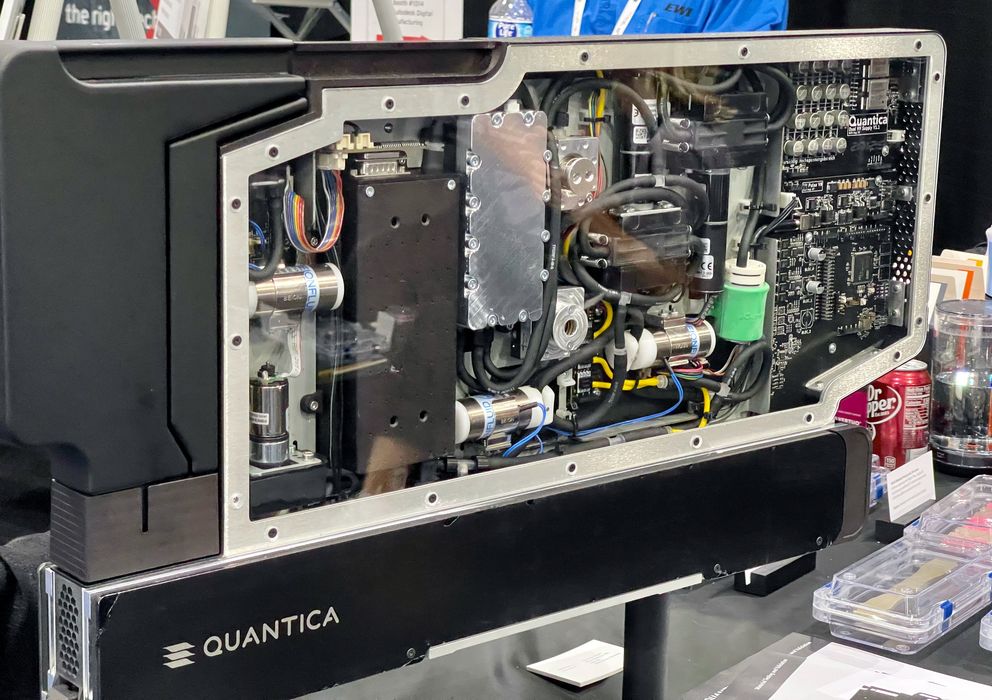

I had a look Quantica’s innovative high-pressure NovoJet system.

Berlin-based Quantica has developed a unique inkjet-based 3D printhead called NovoJet. It operates at far higher pressures than normal inkjets, allowing the use of much thicker resins.

Thick resins are important because they allow for a far greater range of material properties, and in particular, strength. Typical resin 3D prints tend to be rather fragile, which limits the possible applications. The NovoJet system should overcome this barrier. We were told their resins can have as much as 75% particle loading, far more than typical resins.

The company’s initial NovoJet technology had a toolhead with 24 nozzles. Now they’ve improved that to a huge 96 nozzles. They’ve now finalized the commercial version of their equipment, and the system shown above is the NovoJet OPEN, billed as:

“An inkjet-based benchtop printer with the unique capability to combine high viscosity materials.”

NovoJet is still quite new and the company is exploring a wide range of applications. This is normal for a new technology, as it may take some time to “land” on a specific “killer application”.

I was told, however, that the company has seen quite a few dental applications. There are a couple of reasons for this.

First, Quantica’s system allows for multimaterial printing, and that’s something that is often required in dental applications. Secondly, the material properties of the thicker resins allow for printing of super-hard materials similar to teeth.

They’re also finding that some customers aren’t so much interested in the Quantica system, but in fact just want the printhead. It seems there is considerable interest in the printhead for 2D applications, not 3D.

For example, they have a customer producing 2D fuel cells for electric vehicles. Another example is printing of 2D adhesive film, which previously had been done in non-digital fashion. They’ve also found much industry interest in printing coatings on surfaces, which is possible with the wider range of possible materials.

The result of the high interest for 2D applications has the company considering their strategy: should they focus on 2D applications instead of their original strategy of 3D printing?

It could be a tough decision to make, but the 2D market for their technology is far, far larger than the entire 3D printing market.

Perhaps they should do both.

Via Quantica