QUALUP SAS introduced two interesting new features on their Qu4 HT high temperature 3D printer.

The French company has produced a series of professional high temperature machines, with their latest being the Qu4 HT. It’s the successor to the Qu3 HT, which was launched in 2022.

The Qu4 HT has a build volume of 400 x 400 x 400 mm, and can be increased on request to 500 x 500 x 500 mm. However, this machine is all about thermal control.

It can heat the build chamber extraordinarily quickly (140C in only three minutes!) and can reach a whopping 300C — as the chamber temperature. And there’s more: the Qu4 HT’s chamber is heated with a laminar flow of air, meaning that every cubic centimeter of the build volume should have the same temperature. That corresponds to very high quality printed parts.

There’s two new features available on the Qu4 HT.

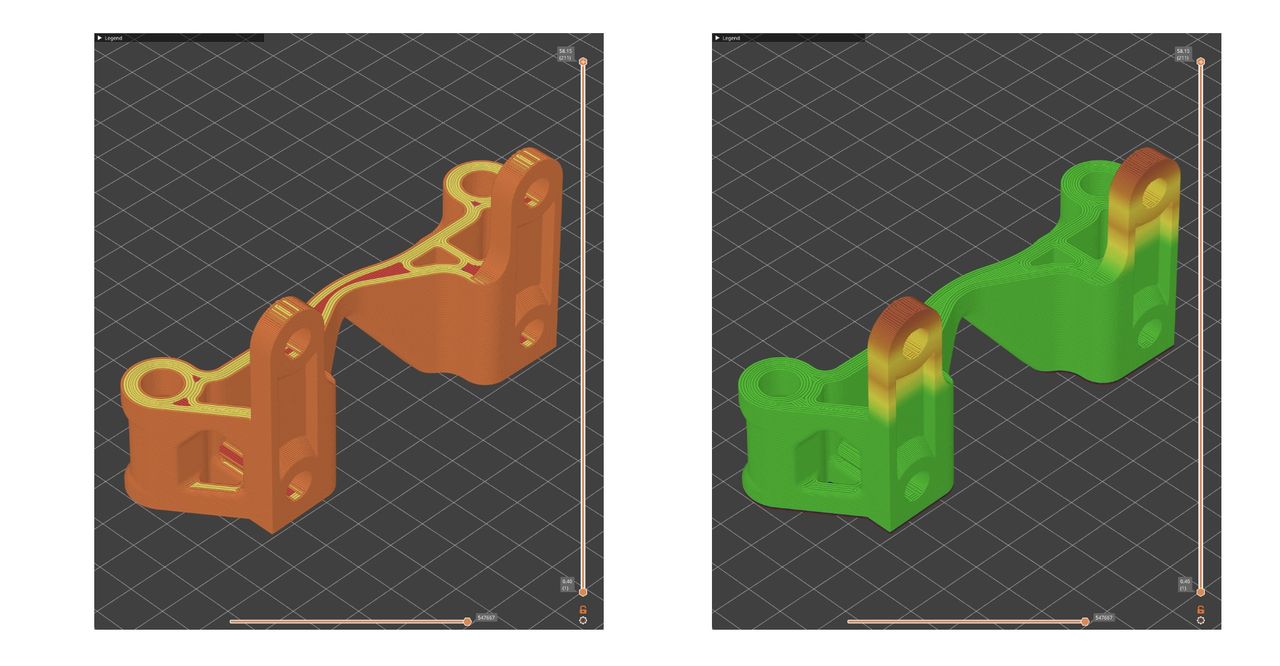

One is a predictive AI system, QU PREDICT. This quite different from some AI systems that perform real time adjustments based on monitoring the state of the print. QUALUP SAS believes that approach is unreliable, and instead goes a step ahead with their AI concept.

Their idea is to perform a highly detailed analysis of the generated GCODE before the print to identify issues, and then tweak the GCODE to avoid them. This means there is less need for realtime monitoring, as problems should have already been fixed.

QUALUP SAS believes their twelve years in the business and eight years working with high temperature polymers provides sufficient training data for their AI system. Items of analysis include:

- Layer stability

- Hot areas

- Layers with risk of error

- Warping risk

- Support management

- Part stability

- Thermal energy accumulation

This is an interesting approach, and I’m sure it does increase print reliability and quality.

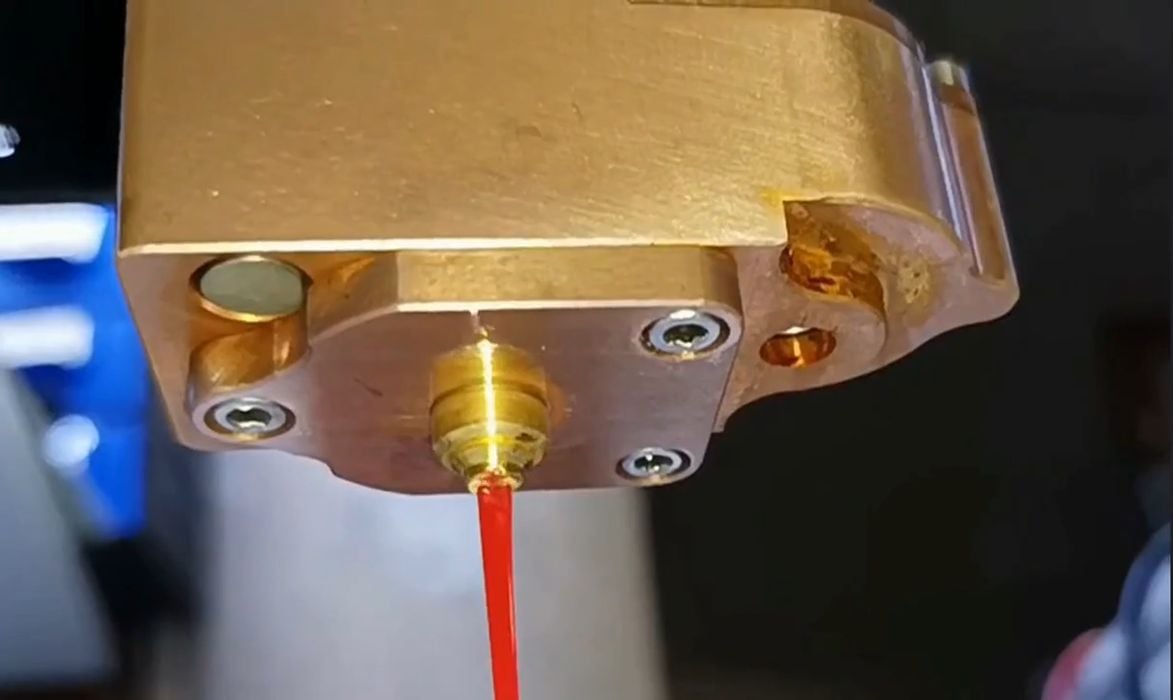

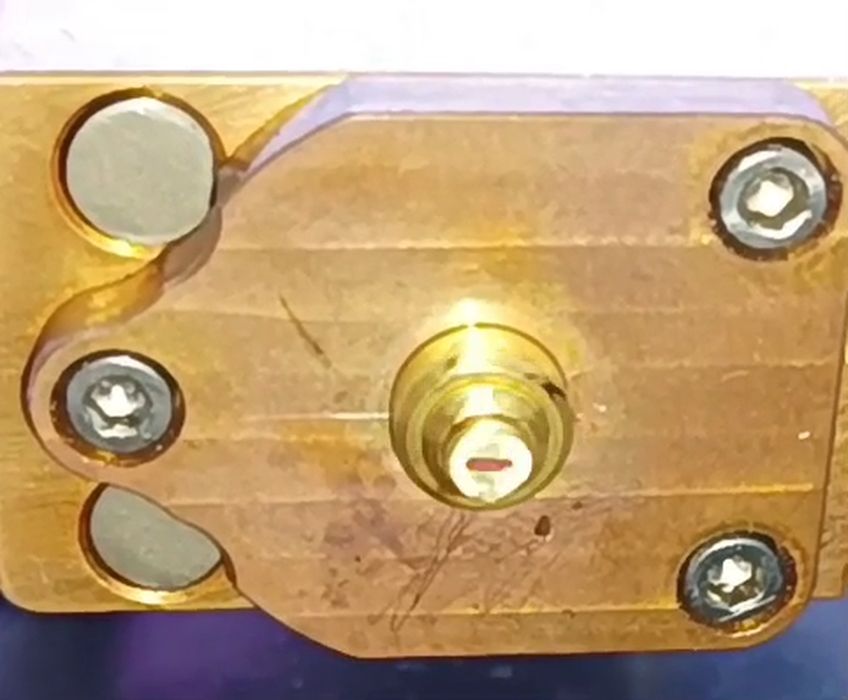

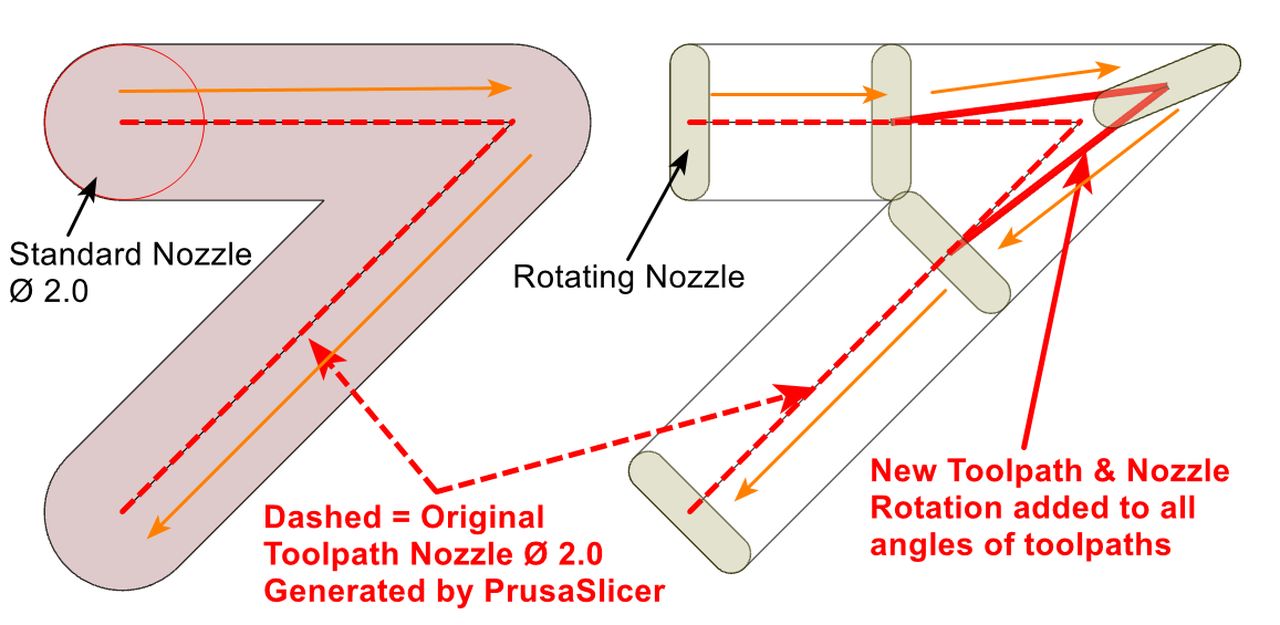

The second innovation is a bit less complex, but also quite interesting. It’s a specialized rotating nozzle, the PIVOT, that can extrude in a rectangular rather than circular orifice. Typically the wide is oriented perpendicular to the path of movement for maximum extrusion.

This allows for wide extrusions that might save print time, but also can sharpen the corners of prints. This is done by skillfully rotating the nozzle at just the right moment when printing corners or edges.

QUALUP SAS said this nozzle can deliver material at the same rate as a 1.5mm diameter conventional nozzle, yet still achieve 0.25mm accuracy on corners.

These two innovations should make the Qu4 HT an even more attractive option for high temperature 3D printing.

Via QUALUP SAS