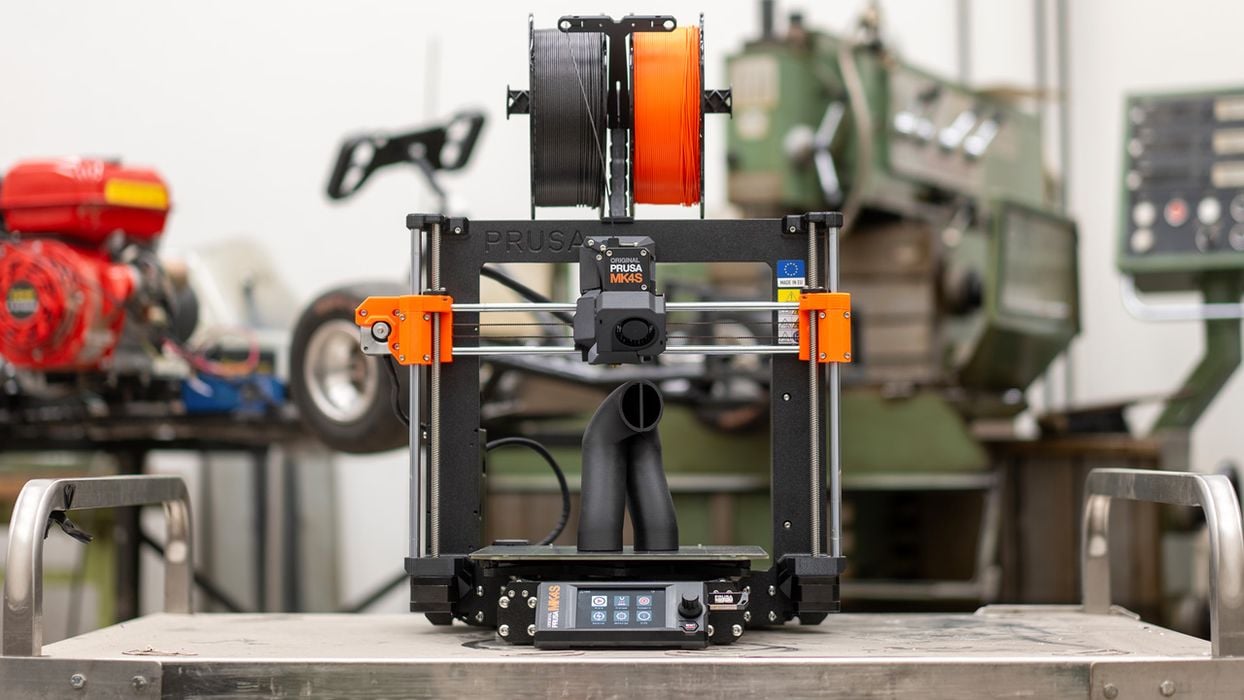

Sticking to the pattern, Prusa Research announced the Original Prusa MK4S this week.

The MK4S is an enhanced version of the MK4, which was announced in March of last year. The “S” approach was also used with the MK3, which became the MK3S — and then the MK3S+.

The upgrade is no doubt a number of design tweaks that Prusa Research engineers developed after the release of the original MK4.

What’s the difference in the MK4S? It turns out the MK4S is significantly enhanced over the MK4.

The upgrade is mostly focused on performance and speed, with several features contributing to print quality.

Prusa MK4S Cooling

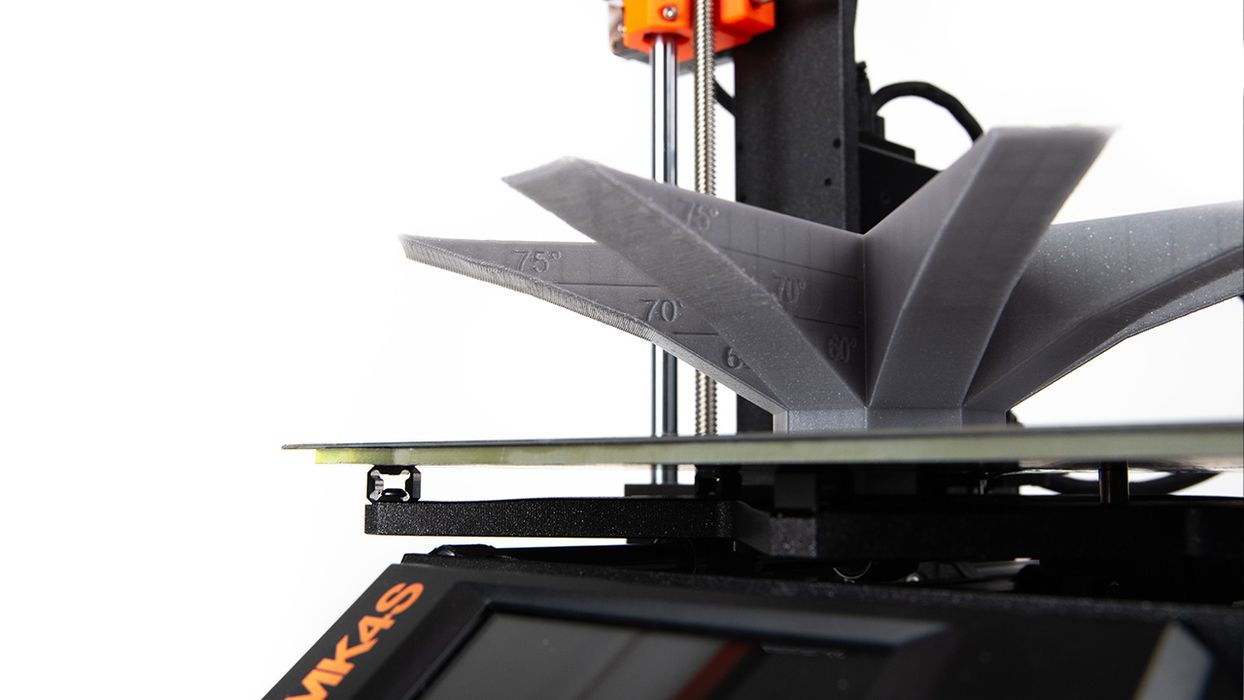

The major change is in the cooling, which has been completed redeveloped. Prusa engineers used airflow simulations to enable far more efficient cooling, and at the same time isolate the cooling to the model, not the hot end. The result was apparently so effective that the fan normally runs at only 60-70%, rather than 100%.

There are three major benefits from the advanced cooling upgrade.

The first advantage is print speed. For smaller layers it’s critical to freeze the extrusion so that the subsequent layer can have a solid foundation. Poor cooling would result in slumps, which will be rare on the MK4S.

Another advantage is print quality. As the material is extruded, the efficient cooling will near instantly freeze, preventing minor slumps that might mess up fine details.

Finally, the quick cooling dramatically reduces the need for support structures: there isn’t time for the material to fall down before it is frozen. According to Prusa Research, the MK4S can handle overhangs up to a whopping 75 degrees before supports are normally required. That will not only save material, but also increase the surface quality where support structures would normally be attached.

Prusa CHT Nozzle

The MK4S now includes a “CHT-style” nozzle that increases the maximum flow rate. “CHT-style” nozzles include some type of metal flange in the extrusion path to expose the more hot surface area to passing polymers. This basically makes the nozzle more easily able to rapidly heat plastic, increasing the flow rate.

Prusa Research indicates the new nozzle can increase flow rates by around 50%, depending on the material. With the larger 0.6mm nozzle, the effects are greater and flow rates can be up to 114% (for PC material).

The cooling and CHT-style nozzle combine to make the MK4S capable of faster printing. Prusa Research has also tweaked the firmware, making the MK4S somewhat faster overall. However, results always depend on the materials and models being used. The stock MK4S can 3D print a #3DBenchy in a very respectable 14 minutes, but the company is able to “specially tune” the settings and get it done in only eight minutes.

Prusa App

Along with the MK4S hardware enhancements, the company also announced a new mobile app. The new app provides a clean interface to any Prusa Connect-compatible device you’re permitted to use. The app provides basic monitoring and controls, but also directly connects to the company’s Printables 3D model repository. From the app it’s possible to directly slice 3D models and start print jobs, which will be quite useful for new 3D printer operators.

Prusa Research points out that the app is “entirely optional”, and there is no requirement to connect to a server to operate a MK4S. This is likely to contrast against their major competitor, Bambu Lab, which by default requires a connection to their cloud for operations.

Finally, Prusa Research also announced a special “hackerboard” attachment for advanced operators. The board connects directly to the electronics of the MK4S and allows the 3D printer to use GCODE to control the board. This means it would be possible to, for example, trigger some cool lighting effects as the print proceeds, or perhaps launch your seven axis robot to remove a completed print — if you had one handy.

The new MK4S is, as usual, provided in both kit and assembled form, with the latter being a bit more expensive. However, Prusa Research said the assembled version can be printing in as little as 15 minutes. The kit sells for US$799, and the kit for US$1099. These are typical prices, and in fact match the MK4 pricing.

There’s also an option to upgrade an existing MK4 to a MK4S, something Prusa Research usually does on equipment. The upgrade would replace the cooling system, firmware and nozzle, and make the device the same as a “real” MK4S. The upgrade is available for only US$99 (€109 incl VAT), which is quite a good deal for the features in the MK4S.

This is an impressive upgrade for the company, and should help them compete against the rest of the market.

Via Prusa Research