So you want to do FFF 3D printing? Here’s ten things you have to know.

For years the idea of desktop FFF 3D printing has been quite challenging. The inconsistent equipment and materials led to an enormous amount of learning that each participant had to gain, usually by trial and error.

Nowadays desktop FFF 3D printers are far more forgiving and include copious automation. They are available at very good price points, and this has attracted even more people to the technology.

I thought it wise to provide some tips that might not be as visible to those newcomers that are considering buying a desktop FFF 3D printer. It’s easy to look at the specifications, but there are a number of other important things to know that the manufacturers might not tell you. Keep these in mind:

Assembly

Most inexpensive desktop FFF 3D printers require assembly. The manufacturers do their best to reduce the assembly effort, but at the same time have to break down the machine to minimize the shipping volume.

Typically you’re receiving a two-part machine, where you have to bolt the base to the gantry. Any cabling between the two parts must be re-attached.

What you need to know is that in far too many cases the assembly instructions are terrible, particularly from Asian manufacturers. They are printed in microscopic format that is effectively unreadable, particularly tiny diagrams, and frequently include translation errors — or just errors.

Early 3D printer operators tended to be hardware techies that were easily able to overcome those challenges, but new machines can attract those less familiar with hardware assembly. They depend more on those instructions and could get into trouble.

The advice here is to go slow, read all the instructions first, practice each step to make sure you understand what’s going on and why it’s required. If not, you may end up taking the machine apart and doing it all again.

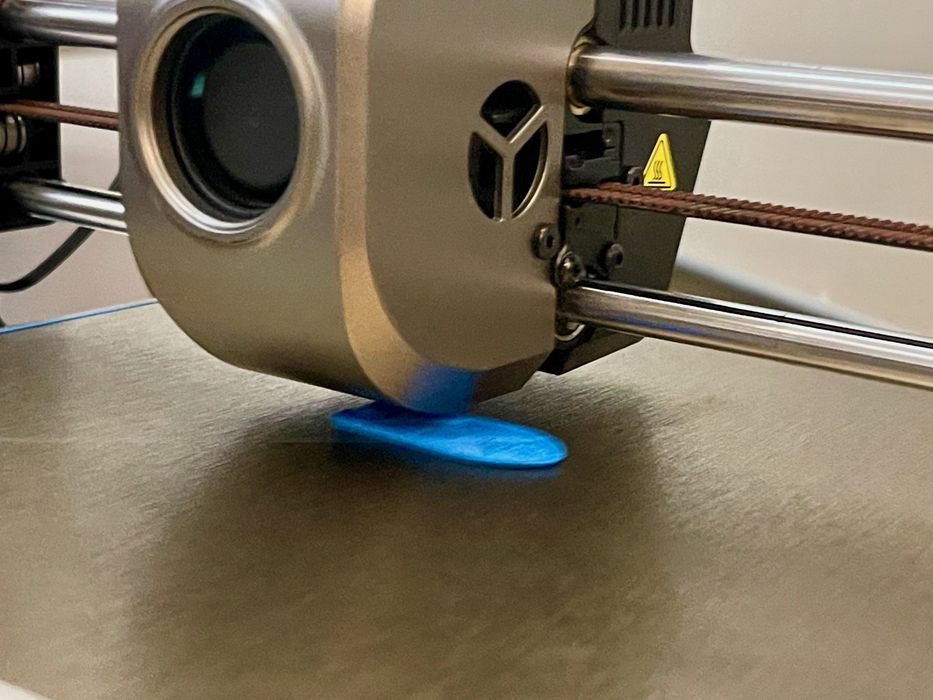

Adhesion

By far the biggest problem will be adhesion to the print plate. If the print isn’t properly stuck, it will tip over during the print job and cause not only a print failure, but potentially damage the machine.

The solution is to ensure the plate is leveled, which should be done automatically, but often forgotten if the plate is replaced. The plate must also be periodically washed with IPA or dish soap.

Supports

Another common reason for print failures is poor support structures. Due to the layer by layer nature of the FFF process, some portions may be overhangs without anything underneath them. Support structures hold things up while that happens.

But support structures are also required in other instances. Many desktop FFF devices use the “bedslinger” motion system concept, where the print surface shifts forward and backward during printing. That’s fine for short objects, but tall ones will flap back and forth, messing up the print and even detaching from the plate. In those situations more supports must be added, even if there are no overhangs.

Support Gaps

Support structures, while very important, also are quite troublesome. They leave marks on the print surfaces that sometimes must be sanded off.

Sometimes the supports stick too well and they are very difficult to remove. In this case you must adjust the print parameter that specifies the gap between the support and the model. Typically it should be about one layer’s width.

Safety

While FFF 3D printers are generally safe, there are a couple of considerations.

Hot plastic will emit some level of Microparticles and volatile organic compounds (VOCs). VOCs are worse on certain materials, like ABS. Because of this it’s advised to ensure there is active ventilation for your device, and never have a 3D printer in the bedroom.

It’s possible to get hurt by touching the hot end — it’s 200C or more — or by sharp pieces when removing support structures.

Cloud

Many recent desktop FFF 3D printers come with an associated cloud system. The idea is for you to login to the manufacturer’s cloud to monitor and control your device. You can usually also store and find 3D models.

It’s all very convenient — if you use only that manufacturer’s equipment. If you have different 3D printers, you will end up using a variety of cloud systems and software tools that can be quite confusing. With new and better machines coming out constantly, it’s very likely you will end up with logins all over the place.

Design

There are multiple online 3D model repositories, each usually associated with one of the 3D printer manufacturers. These would be sites like Printables (Prusa), Makerworld (Creality), Thingiverse (UltiMaker), and several others.

While these sites boast many thousands of 3D models (with Thingiverse holding several million), it is usually next to impossible to find what you want. That’s because:

- The search functions are poor

- There are too many variations

- The model doesn’t exist and you can’t tell it doesn’t exist

Just because there are lots of 3D models doesn’t mean you will find what you want. You may need to design your own 3D models.

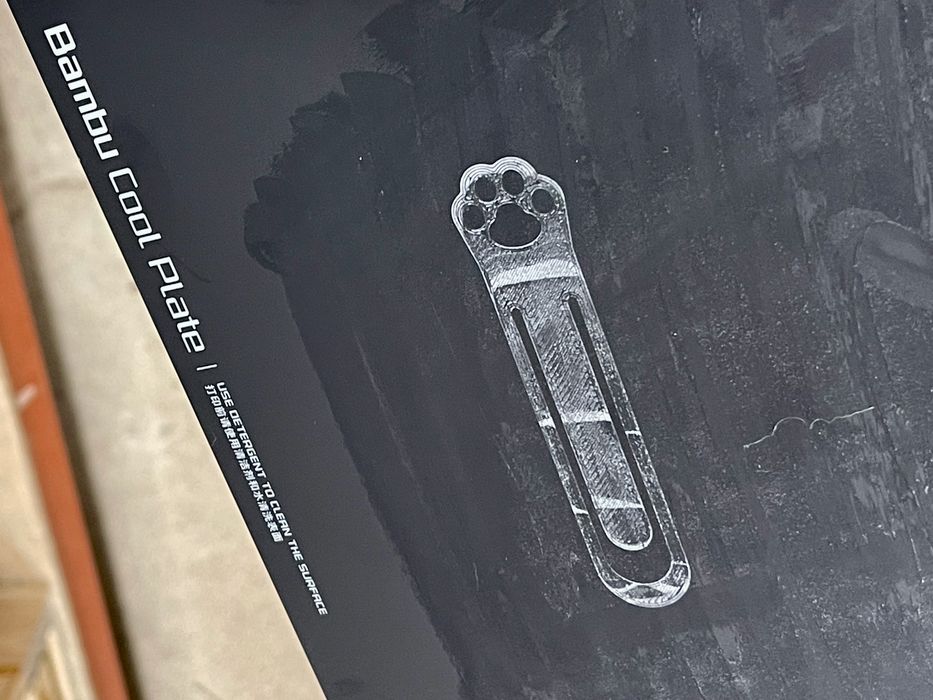

Too Much Adhesion

Some desktop 3D printers ship with a glue stick. It would appear that you have to put glue stick on the print surface to make sure the print sticks.

This is NOT what the glue stick is about.

Print plates are typically coated with PEI, a material that sticks to the most common print materials, such as PLA and ABS. However, due to chemistry different materials have different adhesion to PEI.

PETG is a material that can stick much harder to these plates, sometimes so tightly that it can damage the plate if you rip off the print. The glue stick is used to place a barrier between the print and the plate to lower the amount of adhesion, allowing the print to be removed without damage.

Technological Advancements

In recent years the technology of desktop FFF devices has been completely revolutionized. For many years the machines were mostly the same, technology-wise, but after Bambu Lab introduced high speed equipment, it all changed.

Today’s machines are much faster, more reliable and produce higher quality prints. There’s quite a competition on between manufacturers, and it’s expected that even better machines will soon appear.

In other words, the machine you buy today is very likely to be considered “obsolete” in far shorter time than you imagine. “Good” machines of only two years ago are now basically worthless.

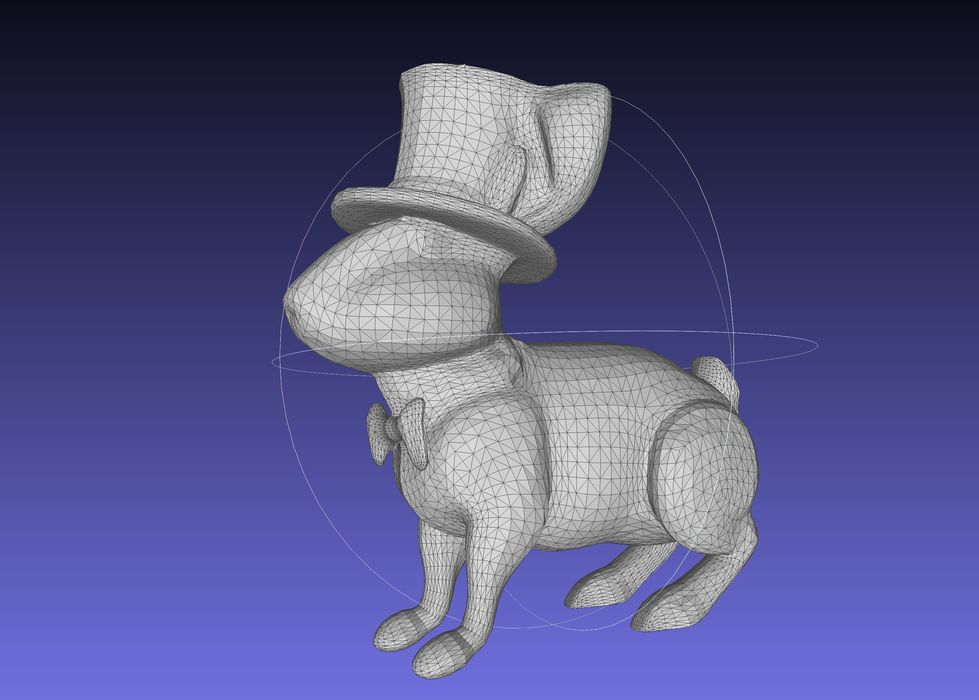

AI Features

Many machines now have some basic AI features, such as automatically detecting a print failure through the webcam. However, that’s just the start. In coming years there will a vast array of Ai-powered functions for desktop 3D printing.

The one that’s now emerging is called “text to 3D”, which will accept a sentence and create a printable 3D model on demand. This is vastly different from the traditional method of making a 3D model with a CAD tool. The old way is expensive, requires a huge amount of learning and takes a lot of time. It’s likely the basic 3D model needs of many new 3D printer operators will be met by these AI tools in the near future, so the thought of spending a huge amount of effort on CAD tools may not be necessary for many.