Piocreat has entered the high temperature 3D printing universe with upgrades to their G5 pellet 3D printer.

Piocreat is a bit of a mystery to some in 3D printing, as they are sometimes confused with Creality. I asked about this and was told they are actually a subsidiary of Creality, and share some technologies. However, the product lines are quite different. Piocreat’s products are mostly for industry, while Creality’s target the desktop environment.

Piocreat’s current product line includes six dental 3D printers, two MSLA devices, six medical 3D printers, three LED letter printers, and three pellet (FGF) 3D printers. The pellet 3D printers include the G5, G12 and G40, with the G5 being of most interest to readers.

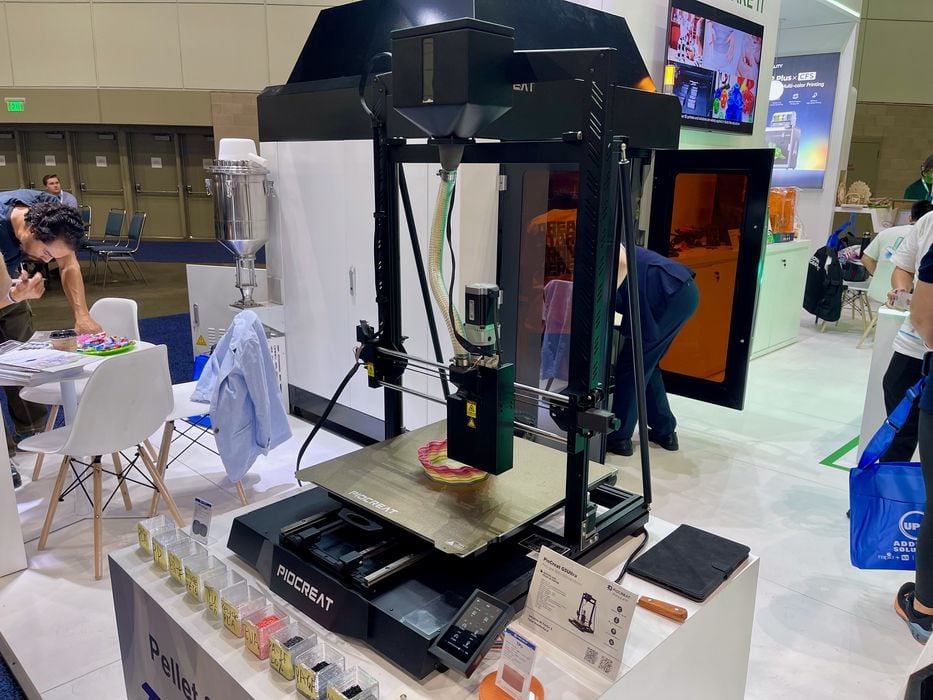

The G5Ultra is the latest iteration of the technology. It visually appears to be a largish Creality-like desktop FFF 3D printer, except for a quite different extrusion system.

That is precisely the point: it’s a desktop 3D printer that uses the FGF process. At the top you will see a hopper in which inexpensive polymer pellets can be loaded. The extrusion system involves a screw mechanism that forces material into the hot end. The rest of the 3D printing process is about the same as FFF, except that retractions are a bit more interesting.

The G5Ultra has an upgraded mainboard, but the more interesting change is the ability to hit far higher temperatures. The new machine now has a nozzle temperature of up to 420C, with a print plate temperature of up to 120C. This places the G5Ultra clearly in the high temperature 3D printer category, and perhaps the only desktop FGF device with those abilities.

It also has a very large build volume of 500 x 500 x 400 mm, so you can print large parts with inexpensive material. Pellets tend to be about 10X less pricey than filament, but you have to buy it by the pallet to get that price point.

One question is the viability of high temperature 3D printing, as the G5Ultra is an open gantry device. Ambient air will cause a significant thermal gradient, and that can generate warping. Piocreat representatives said they also offer an optional enclosure for the G5Ultra, which would solve that problem easily.

Here we can see a closeup of the extrusion system on the G5Ultra. The screw mechanism is hidden inside, so we can’t see it.

Note the circular vent at the top of the extruder. This is very likely used to evacuate the hopper and feed tube when changing materials. Open it up and the pellets pour out. However, there’s likely a requirement to run the extruder for some time to clean out all traces of the prior material.

The G5Ultra’s standard nozzle is a huge 0.8mm, making large prints run quickly. The machine can also use optional 0.4, 1.0, 1.5, 2.0, and 3.0 mm nozzles for faster — but coarser – print jobs.

Pellets capability opens up the possibility to use a wide range of materials, some of which are shown here. The G5Ultra’s high temperature capability means it should be able to handle almost any type of pellet, as long as it meets the dimensional requirements.

The G5Ultra is quite an interesting machine, as it offers the possibility of low-cost, large format 3D printing. It would be best used by operations continually printing large objects where money would be saved on materials.

Via Piocreat