SPONSORED CONTENT

PCBWay introduced a new 3D print service using PolyJet technology.

The rapid prototyping service, which began years ago by producing PCBs on demand, has branched into quite a few other making technologies, including 3D printing. Up to now, they’ve offered a range of 3D printing processes, including FDM, SLA, SLS, SLM, and MJF.

Now they’re adding PolyJet to their portfolio of 3D print services.

PolyJet is a technology from Stratasys, which also happens to be the company behind FDM, also used by PCBWay. PolyJet is a resin-based technology that’s quite powerful.

Here’s how it works:

- A tool arm moves across the print plate.

- The arm has a huge inkjet printhead able to deposit tiny droplets of resin.

- The inkjet printhead selectively drops resin where solid portions of the model exist.

- A second pass of the tool arm illuminates the fresh layer with UV light to solidify the resin.

- Support material is deposited as required in the same manner.

- Layer after layer is deposited and cured, building up the complete object.

- After printing completes, the support material is washed away to reveal the finalized object.

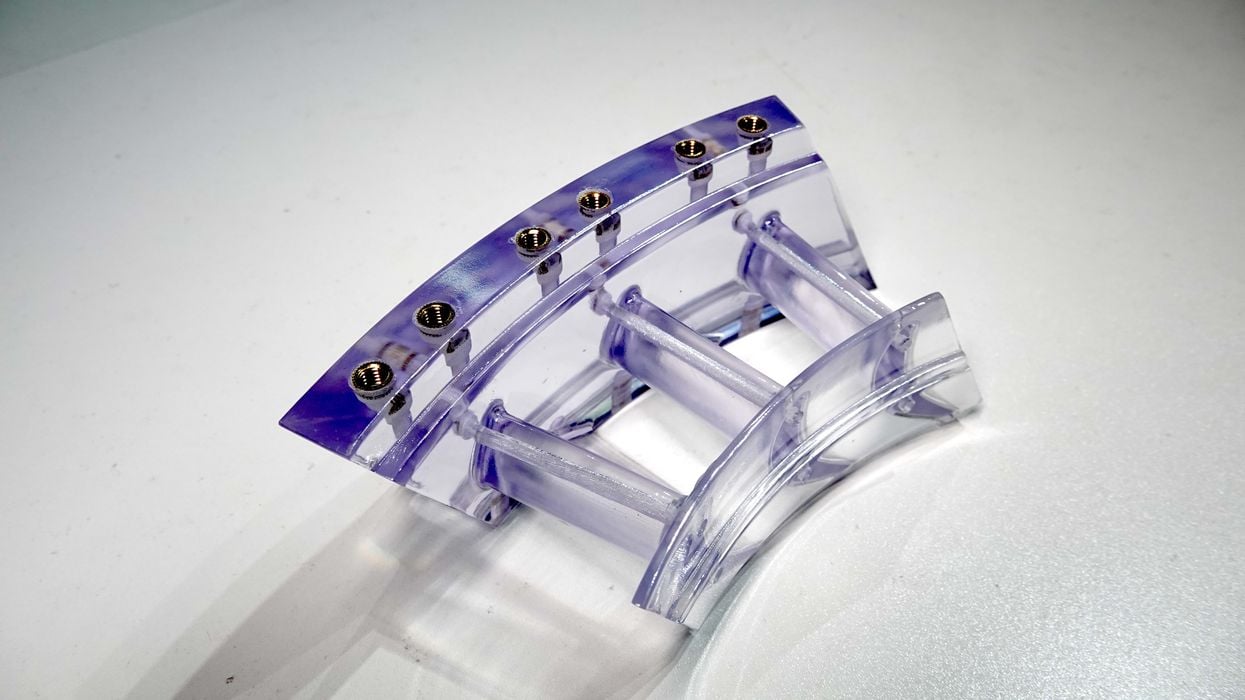

PolyJet technology is very mature and has been used for over 15 years in the industry. It’s commonly used to print high-resolution parts with extra-smooth surfaces, and more recently, parts made from multiple materials.

Over the years, Stratasys has gradually increased the number of possible materials for PolyJet, with many options available. There are materials for not only rigid parts but also flexible, transparent, and specialty materials.

PCBWay now offers print services on their Stratasys J850 Prime 3D printers, which have a massive build volume of 490 x 390 x 200 mm. This should easily be able to handle relatively large parts for prototypes or quantities of smaller parts in a single print job.

PCBWay said the precision on their PolyJet service is quite high, with a minimum wall thickness of only 1.0mm, and a dimensional accuracy of plus or minus 0.1mm for a 100mm part.

PolyJet technology is unique in the 3D print world as it can create “new” materials during printing by mixing resins in different ratios. For example, mixes of rigid and flexible resins can result in a range of hardness. It’s even possible to print a gradient from hard to soft material.

It’s also possible to print in an enormous range of colors by similarly mixing resins. The J850 is able to handle up to seven different resins in the same print job. Stratasys states that their VeroUltra resins can print in over 600,000 different colors.

Tinted parts can also be printed by mixing colors with transparent resins, and this can even be done while printing rigid materials in the same part. It’s therefore possible to print parts with multiple colors and materials in a single print job, something you cannot do with any other 3D print process.

Pricing of PCBWay’s PolyJet service depends on a number of factors, including part size, quantity, materials selected, and any post-processing services used. However, it’s easy to determine a price by using PCBWay’s online quoting system. You simply upload your 3D model, select materials and other options, and PCBWay automatically calculates a price quote.

The benefit of using PCBWay is that they provide not only the 3D printer and materials but also offer quite a wide range of post-processing steps. PolyJet parts usually require minimal post-processing as their surfaces are quite smooth, but there are other steps that can be taken.

PCBWay offers painting, polishing, electroplating, nut or component insertion, glazing, reinforced coatings, and even testing of the completed parts. While some might have access to a 3D printer, they probably don’t have access to these broad post-processing options provided by PCBWay.

If you require high-quality prototype parts made from multiple materials, PCBWay’s new PolyJet service could be what you’re looking for.

Via PCBWay