I tried using a patterned FFF 3D printer plate for the first time.

Patterned plates are a relatively new concept, and most 3D printer operators don’t yet have them.

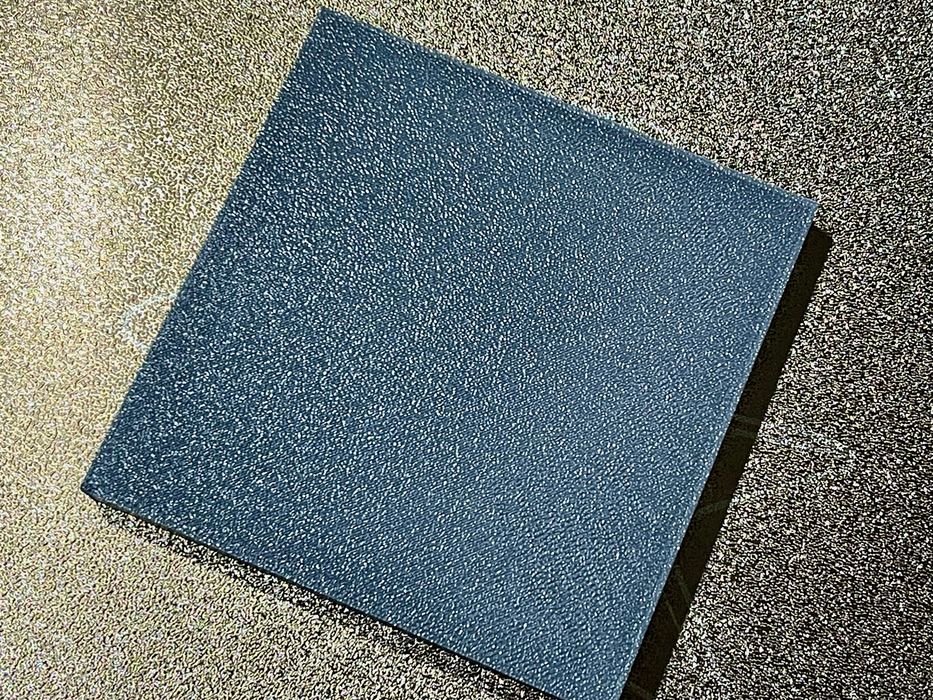

Print plates come in two forms: “flat” and textured. Flat plates are just that: a glass or metal surface that is perfectly flat. “Textured” means there is a “pebbled” surface that often provides a bit more adhesion due to additional surface area.

Prints made with flat plates have perfectly smooth bottoms, while those made on textured plates have the same pebbly texture. The choice between them is a balance between adhesion and surface quality requirements.

Patterned plates are a variation of the textured concept. The idea is to etch a pattern on the surface to provide a bit more surface area, like traditionally textured plates. However, the pattern can take on many forms, and those shapes are easily created by laser etching.

Creality sent me one of their Tenth Anniversary patterned plates for testing on my K1C 3D printer. The plate is double-sided, and above you can see the standard textured side. Note that it has a “10th anniversary” logo on it. I wondered if this would show up on the bottom of a print?

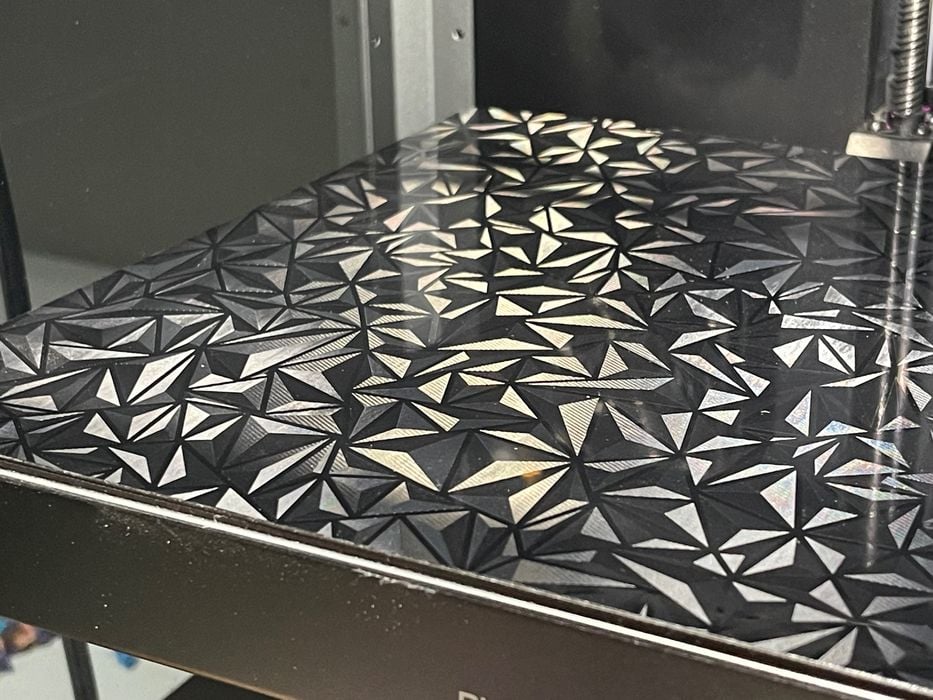

The other side of the plate is the patterned side. Creality’s design choice here was an arrangement of triangles that has a kind of crystal appearance.

After re-leveling, which you must do when you put in a new plate, I first tested the textured side. It worked perfectly, but the logo did not show on the bottom of my print.

I then flipped the plate to test the patterned side. It looks very good in the build chamber of the K1C.

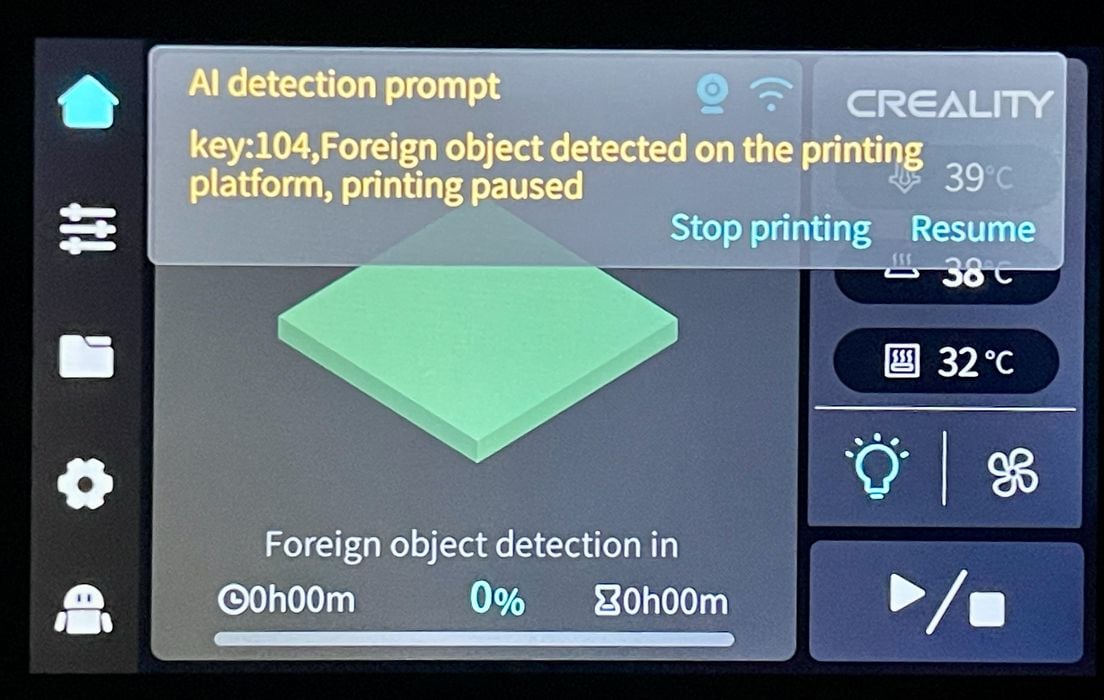

However, when I started the print job, I immediately got this error message. It seems that the AI vision system in the K1C somehow thought that the patterns on the plate were actually a foreign object.

This could be a dilemma for this type of AI function, because patterns by definition are visible artifacts. I can easily see how the detection would be triggered. In this case, I simply hit the “resume” button and the print proceeded.

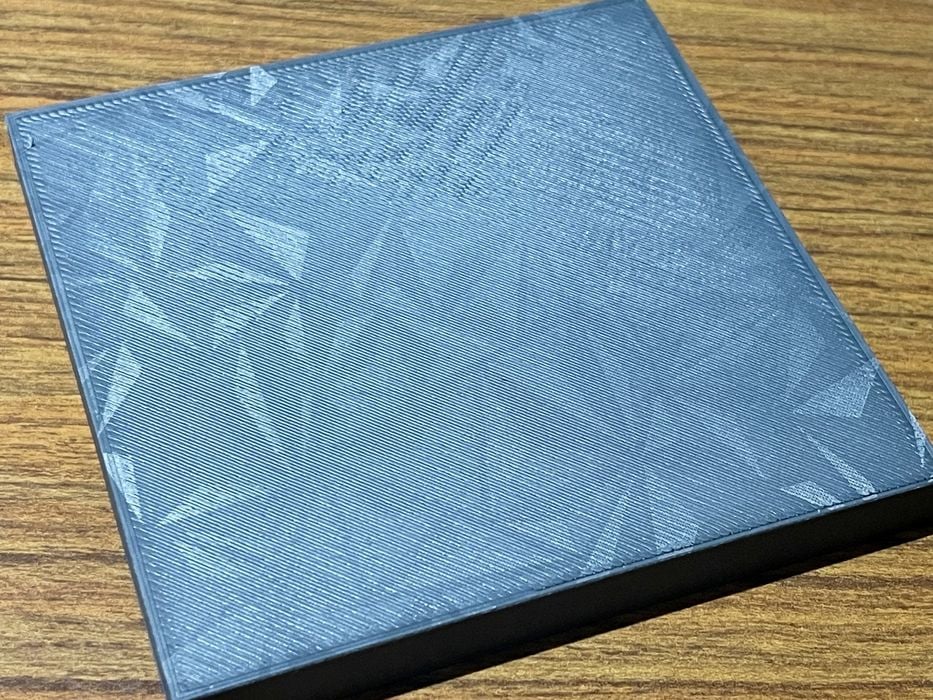

After printing I flipped over the object to see if the pattern made its way onto the bottom, and in fact it did.

I can clearly see the triangle pattern, which looks better in person than this image because it depends on the angle of light. If you move the object around the pattern is far more apparent.

Patterns don’t add any functionality to the prints, but do offer a bit more visual variation. They also look very cool in the build chamber in-between print jobs.

It is possible to obtain a custom patterned build plate from Ember Prototypes. They offer the ability to put your own artwork on build plates, similar to the Creality plate I tested. This opens the possibility to automatically place your own logo on the bottom of every print, for example.

Patterned plates are interesting, and some will definitely find them useful for 3D printing.