Charles R. Goulding and Preeti Sulibhavi unearth how Oshkosh Corporation’s award-winning HARR-E™ and advanced 3D printing initiatives are revolutionizing the specialty vehicle industry while unlocking R&D tax credit opportunities.

Oshkosh Corporation, headquartered in Oshkosh, Wisconsin, is a prominent industrial technology company specializing in the design and manufacture of purpose-built vehicles and equipment. As of 2023, the company employs approximately 17,300 individuals and had approximately US$2.74 billion in sales as of the third quarter of 2024.

Oshkosh’s diverse product portfolio includes specialty and access equipment under brands such as JLG®, Pierce®, Oshkosh® Defense, McNeilus®, and Jerr-Dan®.

Oshkosh Corporation’s receipt of the CES Picks Award at the January 2025 Consumer Electronics Show (CES) in Las Vegas was a major milestone, showcasing the company’s commitment to cutting-edge innovation. The award specifically recognized Oshkosh’s HARR-E™ (Hail-able Autonomous Refuse Robot – Electric), an autonomous and electric waste collection system designed to redefine refuse and recycling operations.

Key Features of HARR-E™

- Autonomy and Efficiency: HARR-E™ integrates advanced autonomous driving technology, allowing it to navigate neighborhoods and industrial zones independently, reducing the need for human intervention.

- On-Demand Service: With the ability to respond to digital “hail” requests, HARR-E™ makes waste collection more flexible and adaptive to customer needs.

- Sustainability: As a fully electric vehicle, it contributes to Oshkosh’s broader goals of sustainability by reducing emissions compared to traditional refuse trucks.

- Advanced Sensors and AI: The system uses cutting-edge sensors and AI algorithms to avoid obstacles, identify waste bins, and optimize routes for maximum efficiency.

The CES Picks Award signifies HARR-E™ as a transformative innovation in the realm of smart cities, demonstrating how Oshkosh’s focus on autonomous and electrified technology can bring practical benefits to urban and industrial communities.

Specific Examples of 3D Printing for End-Use Parts

Oshkosh Corporation’s exploration of additive manufacturing has extended into producing end-use components for its various truck and specialty vehicle lines. Below are some examples:

- Custom Brackets for Military Vehicles

Oshkosh Defense uses 3D printing to produce customized brackets for its tactical vehicles. These brackets, which secure critical components like communications equipment and sensors, are tailored to each vehicle’s configuration. The use of additive manufacturing allows Oshkosh to produce these parts quickly and adapt them for unique mission requirements without the need for costly retooling. - Lightweight Components for Aerial Firefighting Trucks

For its Pierce® firefighting trucks, Oshkosh has leveraged 3D printing to create lightweight, durable parts such as pump mounts and valve housings. These components, made using high-strength composite materials, help reduce vehicle weight, which in turn enhances fuel efficiency and performance. - Dashboard Panels for Refuse Trucks

McNeilus®, Oshkosh’s refuse truck brand, uses 3D printed dashboard panels tailored for specific models. This allows for customization of control layouts based on operator feedback, improving usability and ergonomics while eliminating the need for traditional, mass-produced dashboards. - Replacement Parts for JLG® Access Equipment

Additive manufacturing enables Oshkosh to produce on-demand replacement parts for JLG® aerial work platforms, such as protective covers and motor housings. These parts are often created locally or regionally, reducing lead times and ensuring quick service for customers who require urgent repairs.

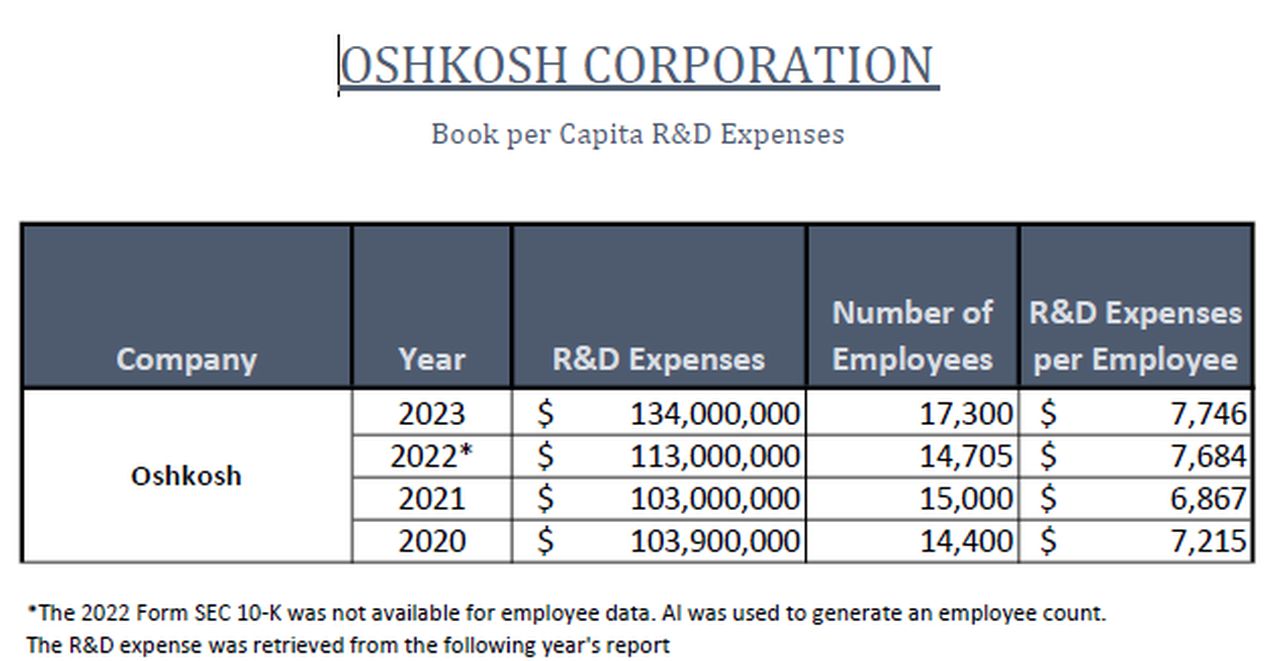

Below is a table that represents the increase in research and development expenditures at Oshkosh over the years. This has enabled Oshkosh to establish its Innovation Center in the Strip District of Pittsburgh, which is about 17,000 square feet and has enabled the company to showcase its commitment to innovation.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Through these initiatives, Oshkosh Corporation is leveraging additive manufacturing to enhance its product development processes, improve manufacturing efficiency, and maintain its position at the forefront of innovation in the specialty vehicle industry. The adoption of 3D printing at Oshkosh Corporation is not merely a nod to innovation but a strategic tool to address modern manufacturing challenges.

By incorporating these advancements, Oshkosh is not only pushing the boundaries of what is possible in vehicle manufacturing but also reinforcing its leadership in delivering customer-focused, mission-critical solutions.