The algorithm is now being trained for Idaho National Laboratory (INL) to apply similar methods for irradiated materials and nuclear fuel.

A software algorithm developed by Oak Ridge National Laboratory (ORNL) has reduced the time needed to inspect 3D printed parts for nuclear applications by 85%. Researchers are now training the algorithm for Idaho National Laboratory (INL) to apply similar methods for irradiated materials and nuclear fuel.

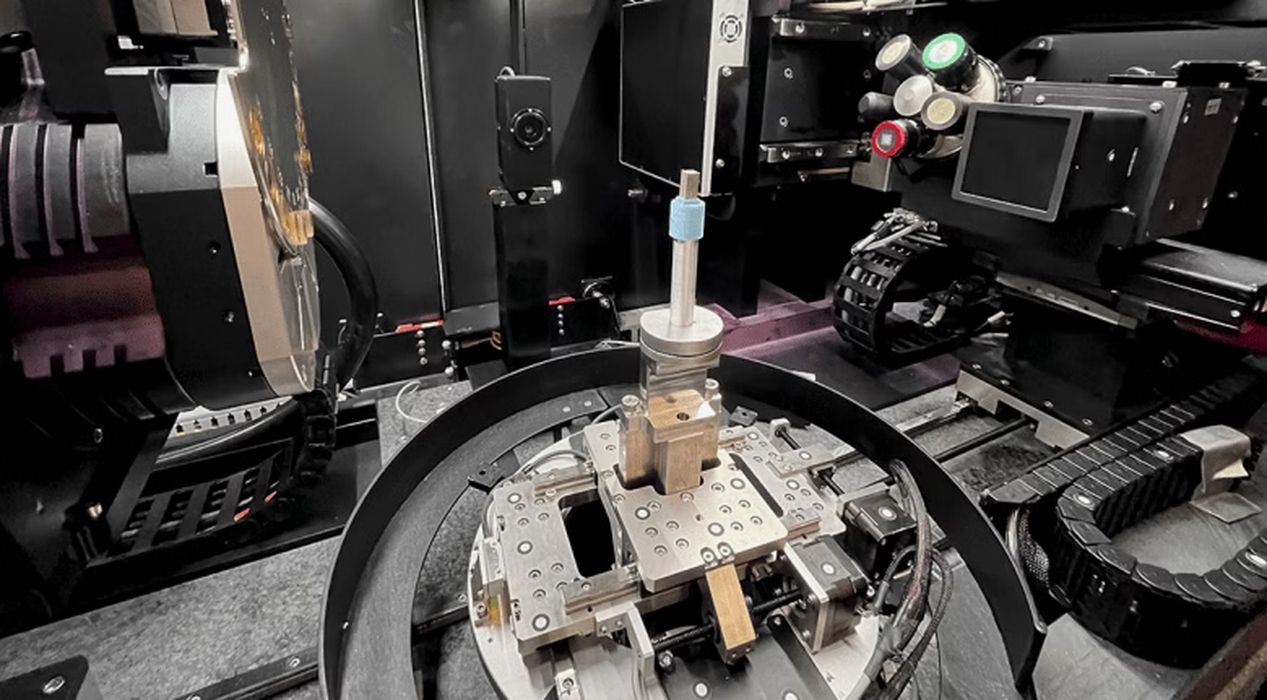

The quality of 3D printed nuclear parts is typically verified through computed tomography or CT scans, which use X-rays to capture images of any weaknesses or errors in the internal structure. ORNL’s new software algorithm uses machine learning to rapidly reconstruct and analyze the images to significantly reduce the cost, time, and number of scans needed to perform an inspection.

Researchers at INL applied ORNL’s new algorithm to analyze more than 30 3D printed sample parts in less than 5 hours of scan time. Previously, it would have taken more than 30 hours to complete each scan without the software – opening the door for potential applications with radioactive materials and fuels.

INL researchers often delay examining materials removed from a nuclear reactor for the safety of lab technicians. Radiation accrued during long X-ray CT scans can also wear on the detector – limiting its operating life and the accuracy of its images. Shorter scans would mean less radiation dosage per scan and less waiting time, while enabling higher-quality data and faster feedback to performance models.

“If we use this algorithm to reduce the scan time for radioactive materials and fuels, it will increase worker safety and the rate we can evaluate new materials,” said Bill Chuirazzi, an instrument scientist and leader of INL’s Diffraction and Imaging group. “Down the road, it enables us to expedite the life cycle of new nuclear ideas from conception to implementation in the power grid.”

Read the rest of this story at VoxelMatters