Orbital Composites offers an impressive range of large format robotic 3D printers.

Composite materials are among the most interesting in 3D printing these days as they provide incredible strength, yet with very little weight. Typical composite materials include polymers mixed with chopped carbon fiber. That makes the material much stronger, but an even better approach is to lay down strands of continuous carbon fiber directly in the print.

Unfortunately there are few machines on the market that can do this. One of them is Orbital Composites.

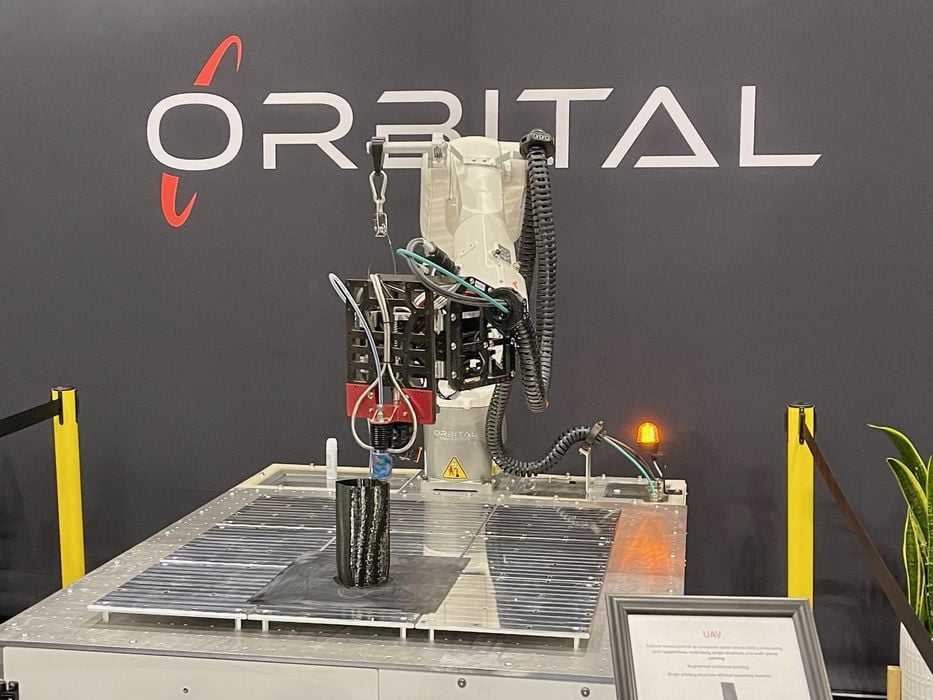

The San Jose-based company, founded in 2015, markets a series of increasingly powerful robotic 3D printers that can not only print large objects in composite materials, but also embed continuous carbon fiber.

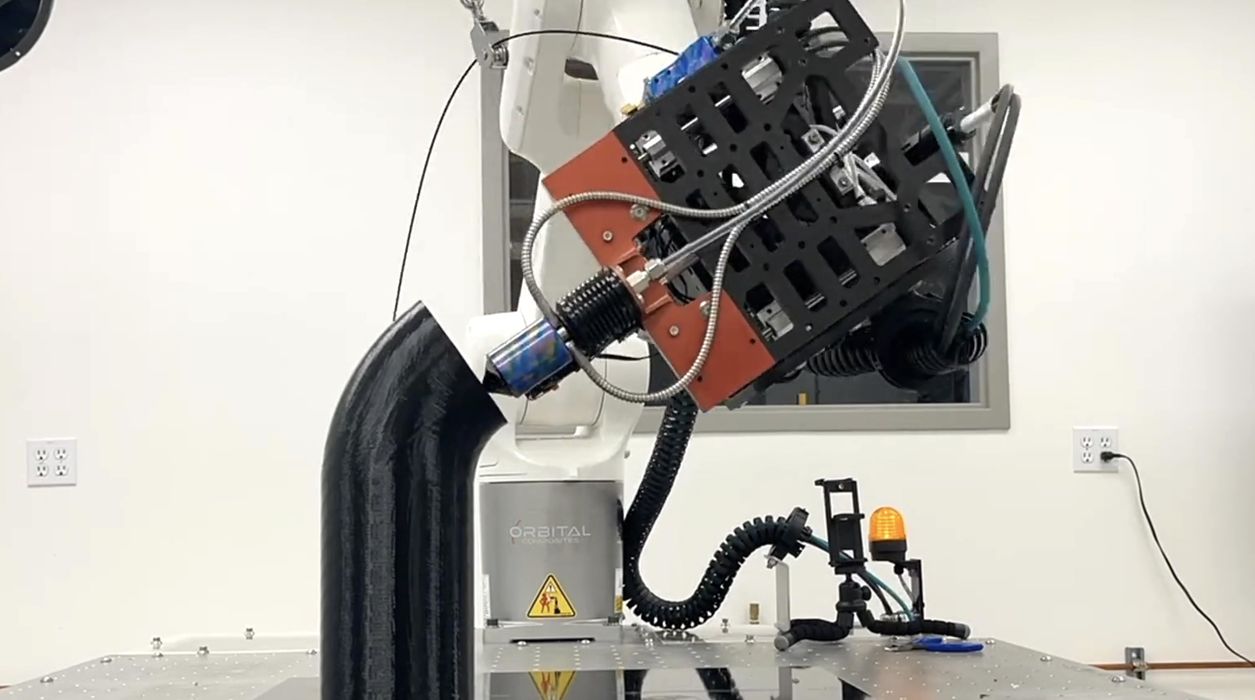

The foundation of their technology is the use of six-axis robots that hold toolheads. The many axes allow the print operation to shift the angle of deposition such that no support structures are required: if there’s an overhang, just tilt the operation to eliminate it.

This allows for easy production because there is no requirement for support structure removal. That’s quite important, given the size of the prints coming off Orbital Composite’s equipment. In addition, there would be far less waste material because no support structures are printed.

The company offers an extraordinarily wide range of printer options, ranging from small, to, well, you will see.

Their “smallest” device is the Orbital e-, billed as an “entry level” device having a single six-axis robot. This device has a build volume of 1100 x 1100 x 1100 mm. It can handle filaments, pellets, continuous carbon fiber and even thermosets. It’s priced at under US$100,000, which is quite good considering the cost of a robot alone.

From there things just get bigger. Their flagship machine is the Orbital S, which has a much larger build volume of 2250 x 2250 x 2250 mm. It has similar capabilities to the Orbital e-, but can have up to SIX six-axis robots in simultaneous operation.

The Orbital F is a bit different. It’s a robot that’s mounted on a track system that fits in a standard 40ft shipping container. The robot slides along the rail, making for a far larger build volume. How big is it? They say it’s “infinitely scalable”, which I take to mean that the rail can be made as long as you want.

They also offer something called the Orbital AMCM, which is a hybrid of 3D printing and injection molding. It’s intended for high volume production.

There is the “SkyBAAM”, for which there are few details. From the imagery, it appears to be a crane-mounted robotic system that can operate on uneven terrain with “unlimited size”. I presume the mobile crane can move the printhead to new areas as required.

Finally, Orbital Composites offers “custom” solutions to meet customer needs. This is not surprising, given the wide range of their listed products. By mixing and matching components it would appear that the company can offer almost any type of large-scale 3D printing solution.