UK-based Noztek announced they’re developing a large-format conveyor-powered build plate for 3D printing.

Belt 3D printers were an up and coming thing a couple of years ago, but interest in them has waned recently, and none of the major 3D printer manufacturers have launched new belt 3D printers in over two years.

The concept seems quite powerful: instead of a static print surface, the conveyor belt slowly moves, allowing continuous printing. Completed prints just roll off the end into a collector. It’s also possible to print items vastly longer than the 3D printer because the conveyor belt just keeps turning.

I experimented with a belt system many years ago and quickly realized the feature instantly transforms a 3D printer into a manufacturing system: it can run almost continuously, producing part after part.

Why they are not more popular is a bit baffling to me, although it may be due to the complexities in using them. In my experience the belts can wear out, losing adhesion and then messing up prints.

Now we see Noztek working on a new belt system, but it’s a little different.

Noztek is not a 3D printer manufacturer, but instead markets a number of related products. These include filament dehydrators, filament winders, “the Pelletizer”, and a variety of filament production systems. They make equipment for filament producers, primarily.

However, they also do a lot of 3D printing, and recently have been using a robotic arm system to do so. They found that they could increase their production throughput through the use of a conveyor system.

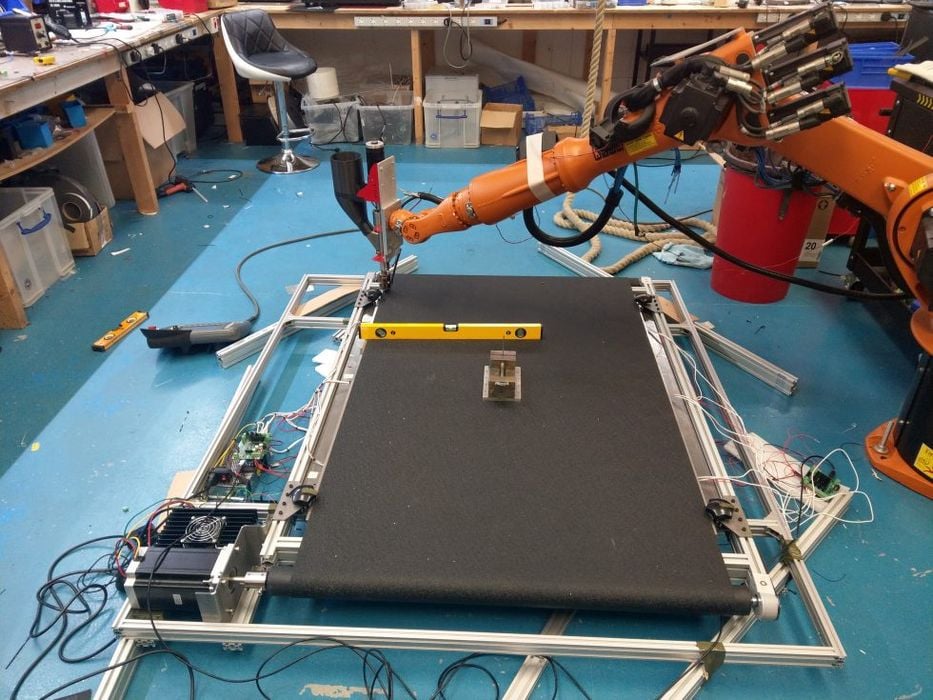

They developed what they call the ”Next Generation Roller Conveyor”. The concept is to use the robot to print objects on the belt, and then when complete the belt does a half revolution. That causes the prints to peel off the belt into a collector, and presents a fresh surface for printing.

That concept permits continuous 3D printing, as the belt keeps rolling off new prints, so long as the operator keeps the 3D printer fed with material.

They believe this concept is ideal for production, explaining:

“We think the key to in-house robotic printing is first and foremost the print bed. If for example you have an order for 200 racing car door mirrors, printing say 6 at a time on a traditional bed would be quite time consuming. If however you had a heated roller conveyor bed connected to your robot controller, you could print 6 at a time, roll the conveyor half a revolution, throw them off the bed, print another 6 and so on.”

Noztek hasn’t published the specifications for the Roller Conveyor, but gauging from the images, it is quite large. I’d guess the print area is about 1000 x 2000 mm, and that’s pretty big.

My questions about the Roller Conveyor would be about the nature of the belt itself. Belts do wear out, and in particular they tend to stretch when repeatedly exposed to the heat of polymer extrusion 3D printing. When stretched they no longer present a flat surface for printing, which can cause issues.

If this system does work, then it could turn out to be a valuable accessory for any robotic-style 3D printer. The combination of the two would, like my desktop example above, convert the system into a production facility with continuous printing.

Via Noztek