Ice 3D printing has been explored by researchers, and it’s far more complex than one may think.

In a recent paper published in the Proceedings of The National Academy Of Sciences, researchers investigated the possibility and methods of 3D printing ice using liquid water.

Conceptually, this sounds quite straightforward: lower the chamber temperature below freezing and then have a toolhead drop water, which would freeze. Many years ago some friends and I even considered designing such a system — because we live in a colder area where an outdoor 3D printer might be a practical thing.

It’s a good thing we didn’t proceed, because it turns out ice 3D printing is fantastically more complex than I had ever imagined. After reading the paper, ice printing involves a highly complex combination of speeds, temperatures and other aspects in order to succeed. The researchers write:

“Controlling 3D-ICE is challenging due to an incomplete understanding of its complex physics involving heat transfer, fluid dynamics, and phase changes.”

And that’s precisely what they investigated in their lengthy paper.

In metal LPBF 3D printing, there is the concept of the “meltpool”, a temporarily hot region made by the laser, which liquifies the metal. The idea is to swing the meltpool around the print bed to form the object.

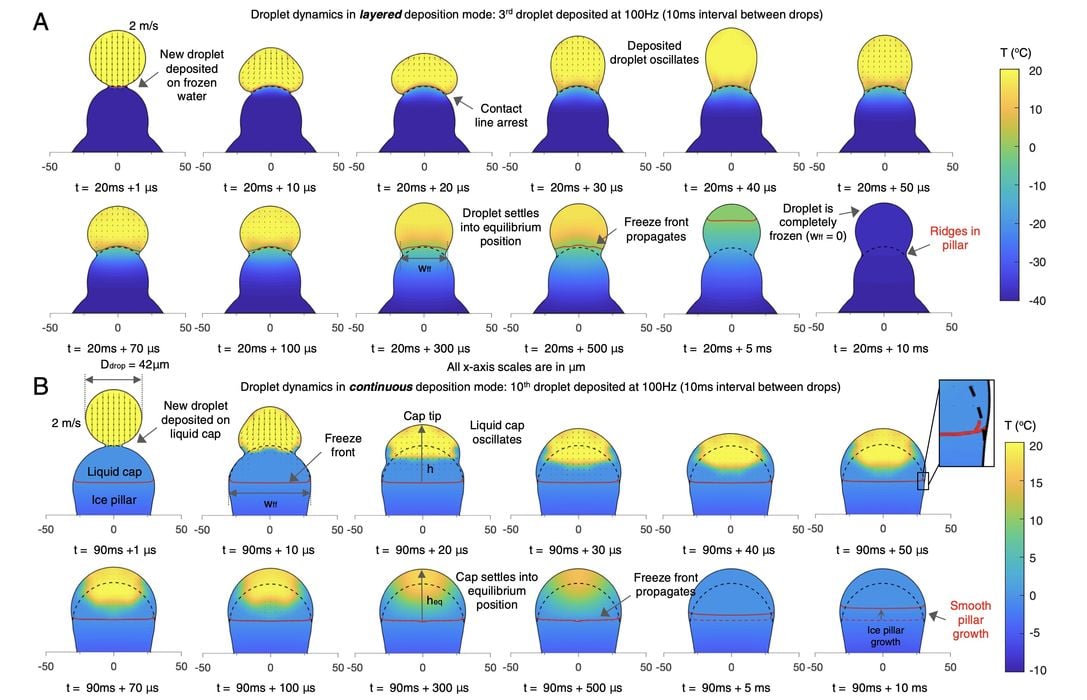

In 3D-ICE there’s a similar concept, except it’s backwards. I’d call it a “freezepool”, where there is a region of transition from liquid to solid that must be moved around the build volume to form the object.

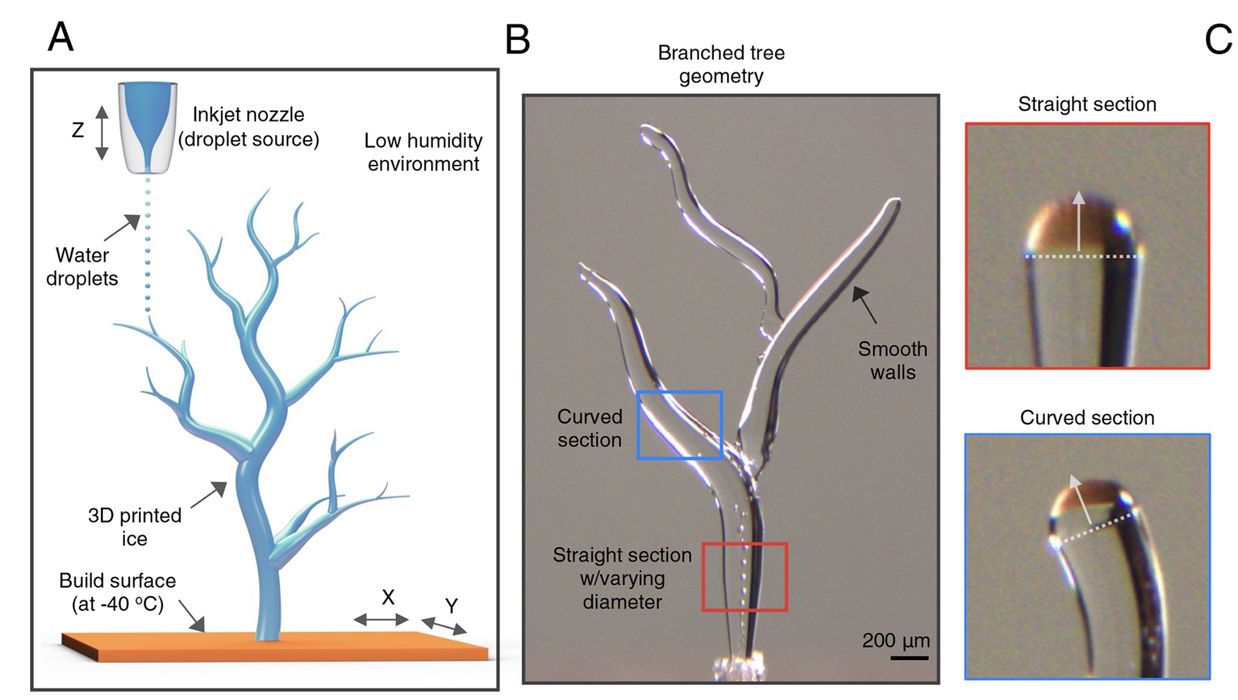

This was deeply investigated by the researchers to determine optimal approaches for “drips” of water to not only freeze smoothly to existing structure, but also allow for movement and some overhang. Above you can see some of the detail of their investigation, which apparently involved a considerable number of experiments.

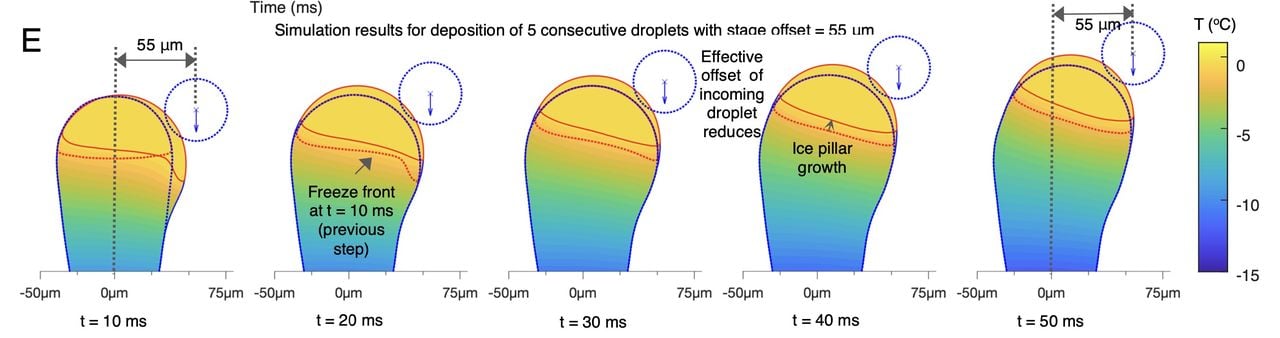

The problems seem to be related to oblique deposition of droplets, where the “freezepool” becomes angled. The researchers developed a computational model to handle this challenge, which modeled the thermo-fluidic activity.

In the end they have identified many characteristics of ice 3D printing that could in the future help build a true ice 3D printer.

But why would you need one?

The suggestion is that ice could serve as a useful support material for certain types of normal 3D printing. Ice, as printed with the continuous process described int he paper, would produce very smooth surfaces that would form a mold to help form desirable shapes. This could be of particular interest to bioprinting.

Obviously, frozen ice would not be useful as a support material for any 3D printing process that operates at above-freezing temperatures, which is most of them. However, the possibility of ice as a support material might trigger some additional thinking about new 3D print processes.

Via PNAS