Researchers have developed a novel method of volumetric 3D printing using microwaves that could speed up resin 3D printing considerably.

Volumetric 3D printing has been a subject of intense research in recent years, and that’s because volumetric additive manufacturing (VAM) has the potential enable near-instant 3D prints.

The concept of VAM involves projecting light patterns into a rotating cylinder of transparent photopolymer resin. As the patterns slide through the rotating resin, some areas receive more or less energy, causing solidification. Basically the whole 3D print happens all at once.

With VAM it’s possible to print small objects in only seconds. Don’t believe me? I’ve actually seen this done in person.

While extremely promising, VAM has several issues. The major problem is that the light patterns can only travel so deep into the resin, and that resin must be mostly transparent (at least in the light frequencies used). This means that only small objects can be created.

This limitation might have been overcome with the latest research from Lawrence Livermore National Laboratory, where microwaves were used instead of normal light frequencies.

Their experiments revealed that microwaves can penetrate resins far more deeply, and even pass into opaque resins. This opens up the possibility of using much more interesting materials with “MVAM”, including composite materials with additives such as carbon black, ceramics or other strengthening materials. However, they found that heating the more viscous resins assisted the process.

Using microwaves has never been attempted in this way, so the researchers had to perform considerable analysis using simulations to understand how microwaves could propagate in the resin, and how to organize the emitters and placements to ensure the correct patterns landed. They explain:

“We created a computational model that couples a microwave beam-forming algorithm with thermal diffusion to enable a fundamental understanding of the effect of microwave absorption and material intrinsic properties on electromagnetic wave propagation. This work predicts curing localization in terms of penetration depth and feature resolution, as required for high-resolution prints. Specifically, we show that microwave energy can be localized to a desired shape using a beam-forming algorithm.”

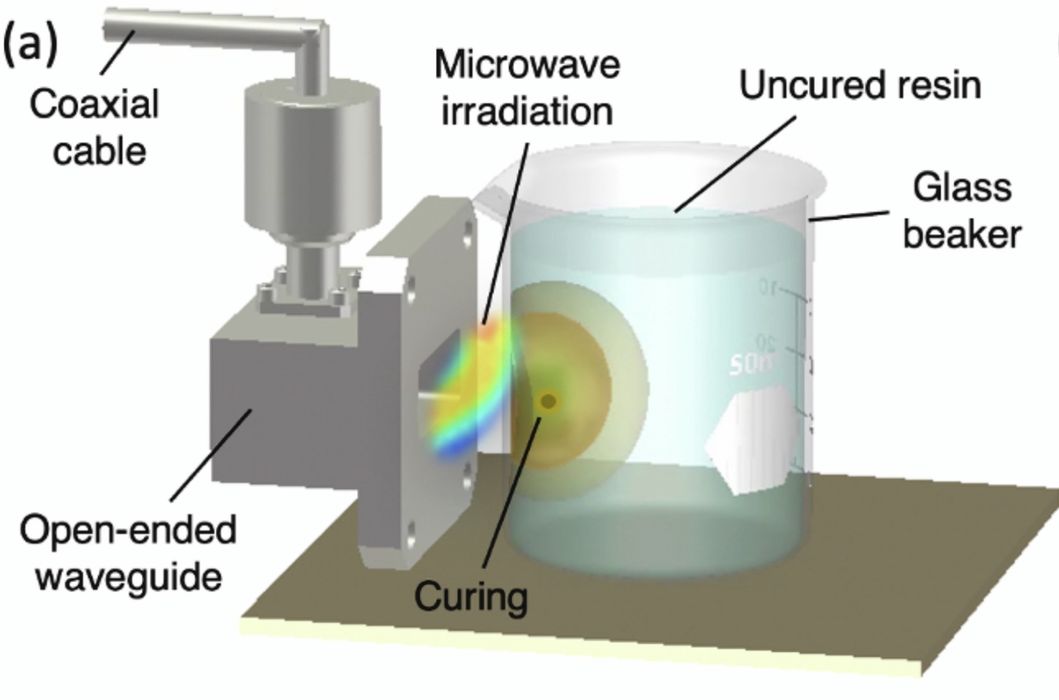

While their design involves multiple microwave antennae, their prototype had only one in order to prove the concept and perform measurements.

Their experiments proved successful, but only after much work testing different arrangements of resin and antenna.

The mathematics behind their computational model are complex, but their simulations and testing were correct.

They found that due to the longer wavelengths of microwave radiation they were only able to produce features ranging from a “few mm to 20mm”. However, they say there are approaches that can potentially increase the resolution.

They also believe that MVAM could potentially be able to print larger objects, as the penetration could reach 100-400mm depth. With a rotating platform this could mean objects up to 800mm long, and that’s more than sufficient for many parts.

They conclude:

“In the future we anticipate volumetric microwave curing of complex geometries will be possible using an array of microwave antennae and dynamic control of spatially-modulated EM fields using the beam-forming technique.”

This very early research will eventually be commercialized, leading to an entirely new range of resin 3D printers.

Via Science Direct (Hat tip to Benjamin)