A quiet, but potentially major development in microscale 3D printing has been achieved.

Researchers developed a new form of resin 3D printing that involves two different types of light sources. Normally, one light source, typically UV light, is used to polymerize a liquid photopolymer resin. This is the fundamental basis of all resin 3D printing today.

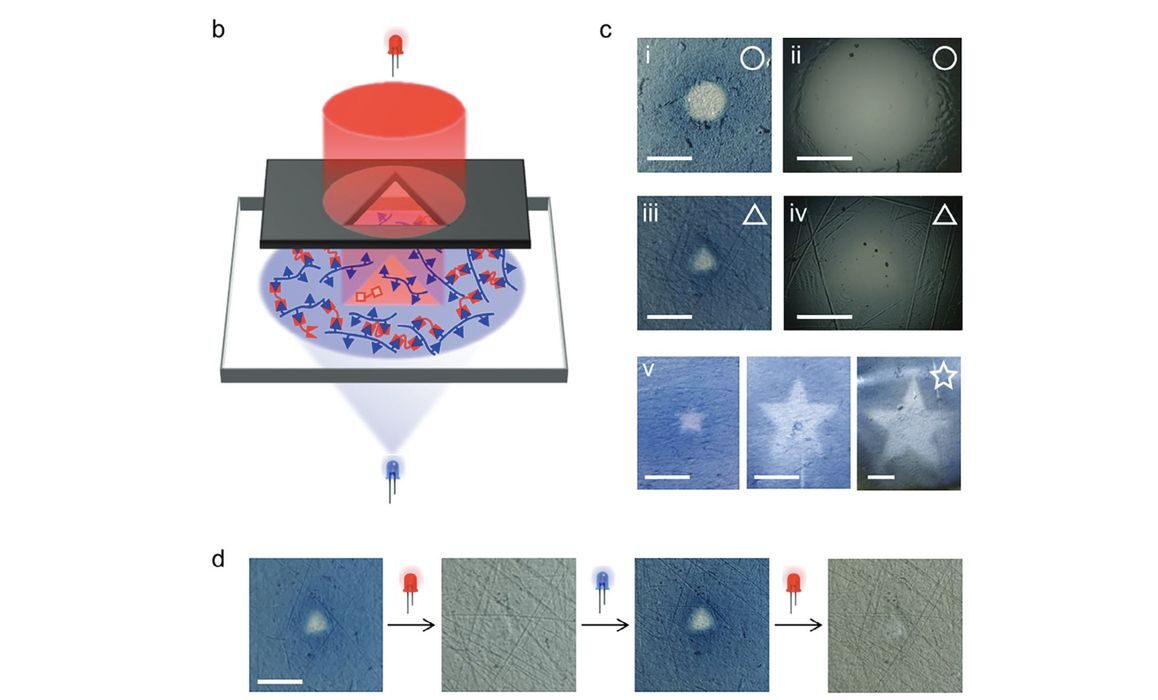

Here, the researchers developed what they call an antagonistic two-color system. One light source is the normal UV light, which is used to polymerize the resin in the usual manner. However, the second light source, red light, is used to inhibit polymerization. That’s the antagonistic relationship: one solidifies, the other stops solidification.

This capability allows on-off spatial and temporal control of material solidification. And that, in turn, means there is the potential for increased 3D print precision if this technology were built into a 3D printer. Enhanced spatiotemporal control reduces errors from diffusion and overcuring — boosting print accuracy and resolution.

The ability to turn polymerization on and off could be extremely useful when 3D printing 4D objects that can change shape after production.

This capability could also lead to much more advanced microscale 3D printing where highly complex objects can be printed at a much faster speed than today’s 2PP microscale 3D printing processes.

The researchers proved their method by printing films, but it should be entirely possible to adapt this technology into a 3D printing system. It’s likely the first implementations of this technology would be for microscale 3D printers, but it remains to be seen how it could be scaled up for larger 3D print volumes.