New research focuses on the problem of overhangs with construction 3D printing (3DCP), with a possible solution inspired by nature.

3DCP is a growing technology, with multiple players in the space. The tech can be used to quickly build large-scale outdoor structures, including walls, sculptures, and even multi-story buildings. However, there’s a problem.

That problem is overhangs. As every 3D printer operator knows, overhangs are present in most 3D models and require the use of support structures to overcome gravity during printing. The support structures are removed as waste after the job completes.

Something similar happens with 3DCP, but it’s worse because concrete as a material has little to no tolerance for overhangs. While it’s possible to 3D print, say, PLA with overhangs of 45 degrees, that’s not possible with wet concrete. It would slump immediately.

Because of this, 3DCP jobs tend to use support materials for most overhangs. A typical example would be for a window hole. The job must be paused while a board is placed at the top of the hole to support the concrete above it. More complex overhangs are rarely even attempted.

That could change with some new research from ETH Zurich and Tsinghua University, where they examined methods of handling overhangs using methods developed in nature.

Specifically, they used lamellae, which is defined by Wikipedia:

“A lamella in biology refers to a thin layer, membrane, or plate of tissue.”

An example would be the thin fins of a mushroom cap, which help hold up the structure. Could something like that be used in 3DCP to enable overhangs and more complex geometries?

It turns out yes, it is possible.

They developed an algorithm that converts a 3D model with overhangs to one that has a form of lamellae to support the overhangs.

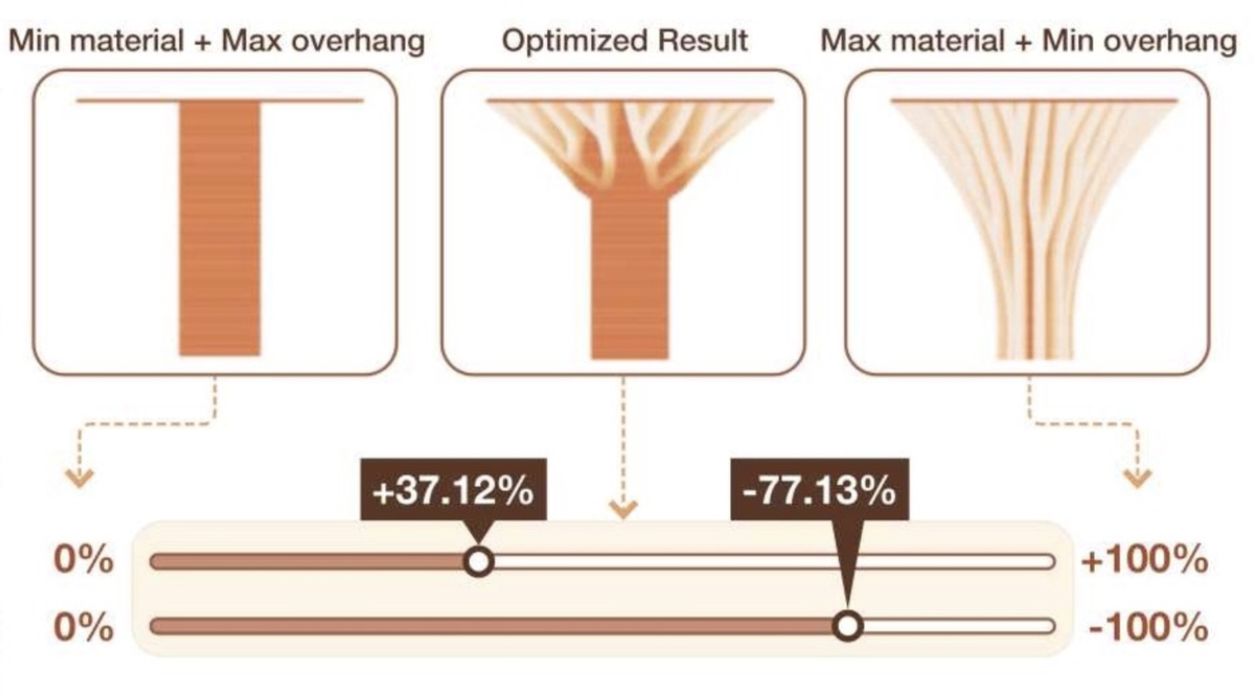

The chart at top shows how it works.

The algorithm has two goals. The first is to make the object fully self-supporting, meaning there is no effort required to deal with supports. This increases productivity because the post-processing steps are simplified.

The second goal is to reduce the amount of material used. 3DCP uses cement, the production of which is one of the world’s major sources of CO2. By reducing the lamellae structures to the minimum required, this reduces the amount of concrete used.

Their “shape variation” algorithm finds an optimal balance between the two goals. They explain:

“The design methods proposed in this study facilitate the creation of large overhang concrete shapes through a simple and repetitive construction process, thereby enabling 3D printing technology to embrace both productivity and sustainability in handling non-standard geometries. The results demonstrate the feasibility of supporting a significant overhang shape (61.85°) with just 13.78 % of the maximum material requirement.”

That’s quite a finding: if this technology were to make it into the CAD systems for 3DCP projects, we may see an explosion of radically different designs for construction projects. Up to now, they’ve been held back by the constraints of the materials and the inability to handle overhangs.

Would it be possible to use this approach on other 3D print processes? I believe designers would like to have a slider that balances support and material in the same manner.

Via Science Direct