UpNano announces modified form of two-photon polymerization for high-resolution additive manufacturing.

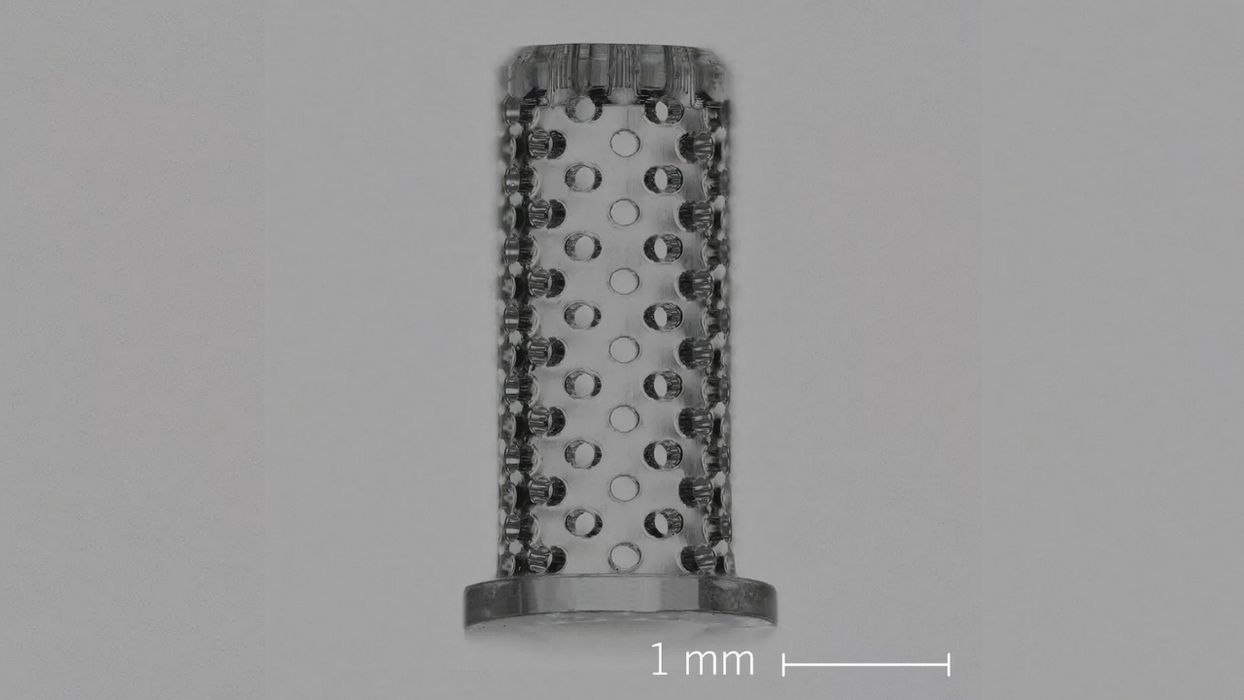

The structure is sintered and fused after exposure to 1,300°C. During the post-processing, the object undergoes isotropic shrinkage of approximately 30%. According to UpNano, this can easily be compensated for by an appropriate upscale of the green part using the company’s software.

“This innovative production process we developed is ideally suited for larger 3D-printed glass parts that require high-resolution and high-precision in the fields of engineering, chemical, medical or research applications, said Lunzer.”

Fused silica benefits and future applications

Fused silica offers superior optical properties, along with biocompatibility as well as high chemical inertness and heat resistance, making it suitable for a range of applications. UpNano claims this new development marks a significant advancement in the potential of 2PP 3D printing.

In addition, the company’s printers have also recently been used to produce holistic embedded microfluidic chips as well as tungsten and platinum microstructures with sub-micrometer resolution.

Read the rest of this story at ENGINEERING.com