Researchers at the University of Edinburgh have developed a method of 3D printing blood vessels.

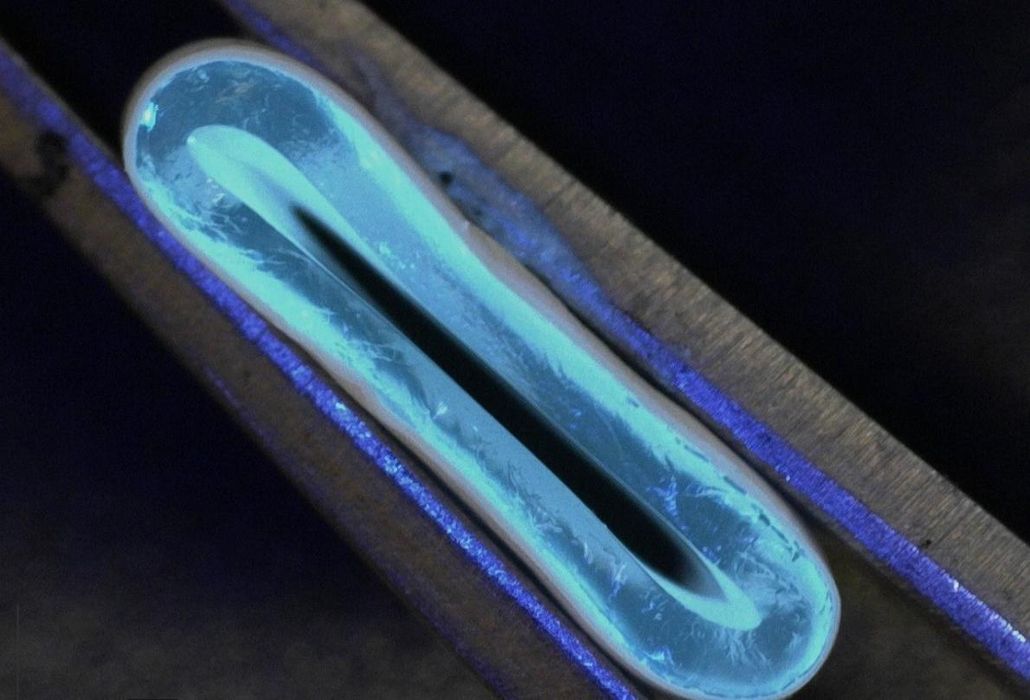

They were able to 3D print the blood vessels by combining a bioprinter with a rotating spindle. The mechanism is able to produce blood vessels in diameters from 40mm, all the way down to 1mm.

Why do this? The researchers were concerned with the traditional method of doing a heart bypass operation, in which surgeons remove existing blood vessels from the patient’s legs and re-install them on the heart to take over from clogged arteries.

If these 3D printed blood vessels prove feasible, it would dramatically simplify heart bypass operations: print the vessels and implant them in a single operation.

There is another very important development for bioprinting in this research.

Bioprinting of tissue has been around for many years, but very typically only small tissue blocks can be printed. This is because, unlike polymer or metal 3D printing, the object is alive. Live cells are deposited on scaffolds during the print job.

These cells must continue living, of course, and that requires access to nutrients, just like they have in a body. Up to now this is most often achieved by allowing nutrients to “soak” through the tissue to the cells.

However, that severely limits the maximum thickness of the tissue because nutrients can only go so far. Because of this it is not really possible to 3D print, say, human organs.

That is, unless you can also print blood vessels to carry nutrients to the cells in the tissue.

Now there seems to be a way to do exactly that.

It may be possible to adapt the new research method into bioprinters to allow for printing of embedded blood vessels while printing other tissue elements.