NASA qualified a very interesting additive manufacturing material for rocket engines.

Recently NASA and partners tested an aluminum powder material from Elementum 3D. Aluminum is not commonly used in LBPF AM systems because it is challenging to print and sometimes cracks due to the thermal conditions.

For rocket engines, aluminum is a very problematic material. While it is quite lightweight, it also has a rather low melt temperature. Rocket engines can get very hot, and that’s not compatible with aluminum.

Nevertheless, NASA embarked on an experiment with Elementum 3D to test an aluminum material produced with that company’s RAM (”Reactive Additive Manufacturing“) process.

RAM is proprietary, but it seems that Elementum 3D has figured out a way to mix additives with a base metal to enable new engineering properties not present in the base material. Currently, the company offers six different blends of aluminum powder, along with others made from steel, nickel, tungsten, copper and even tantalum.

Elementum 3D explains:

”We achieve these high-performance properties in our AM powders through our proprietary, patented Reactive Additive Manufacturing (RAM) technology. The versatile RAM process combines reaction synthesis with additive manufacturing that enables 3D printing of previously unprintable advanced metals, ceramics, and composites. RAM powders exhibit greatly improved properties compared to current state of the art 3D printing materials.”

They say they are able to enable 3D printing of materials that are “beyond what the manufacturing industry thought possible.”

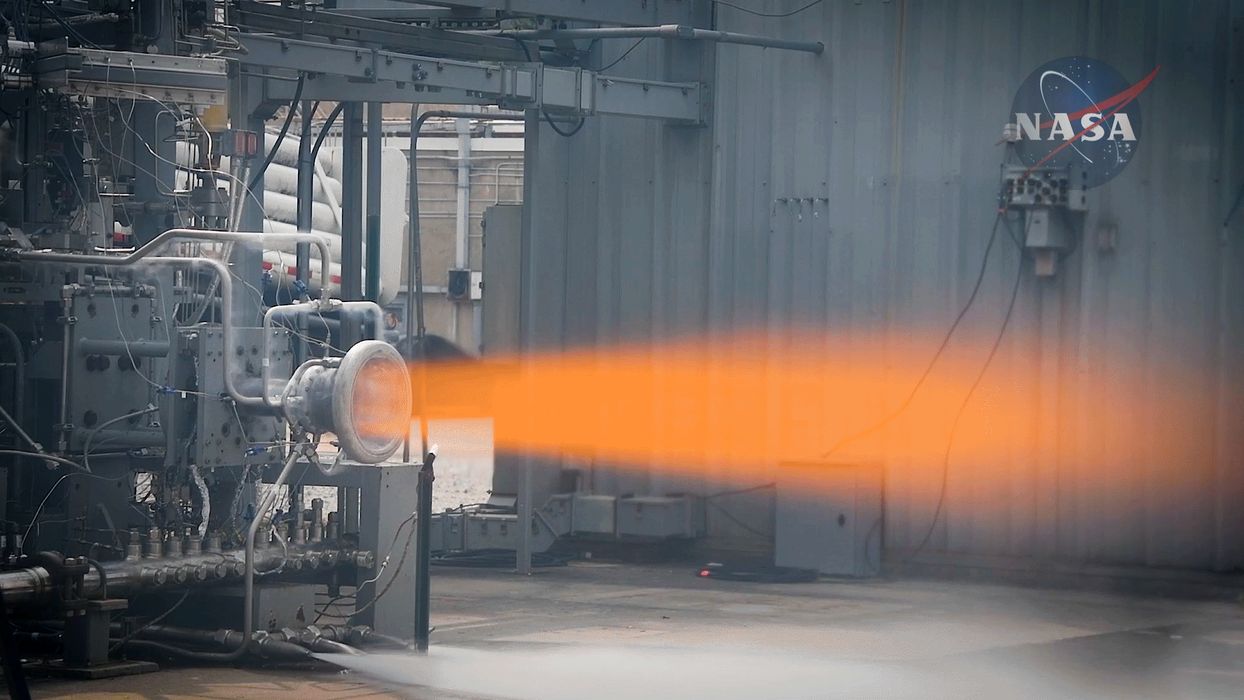

These capabilities were of interest to NASA, which started a project to 3D print a test aerospike-style rocket engine using one of Elementum 3D’s aluminum alloys. The “Broadsword” rocket engine was then tested. NASA explains:

“NASA adopted the technology, qualifying the RAM version of a common aluminum alloy for 3D printing. The agency then awarded funding to Elementum 3D and another company to print the experimental Broadsword rocket engine, demonstrating the concept’s viability.”

While 3D printing has become a de facto standard for the production of advanced rocket engines these days, the use of aluminum has not. That may change as a result of this test: if NASA has qualified the material, others will follow.

Via NASA and Elementum 3D