MIT researchers have developed a method to use sustainable glass as a structural building material.

The building industry is one of the largest sectors in the world, and it also happens to be one of the biggest generators of greenhouse gases. That’s because the most common building material, cement, requires significant heat to be produced, and this is typically done via fossil fuel burning.

Many researchers have sought ways to reduce or even eliminate the CO2 from the cement process, but MIT’s new approach is quite unique: use glass instead of concrete.

Why not? Glass is a strong and hard material, if sufficiently thickened. It is eminently recyclable and commonly available.

One could just cast “lego blocks” made from glass and build structures, but there are quite a few limitations with that approach. Instead, the researchers investigated ways to design glass 3D prints that could be used for structural builds.

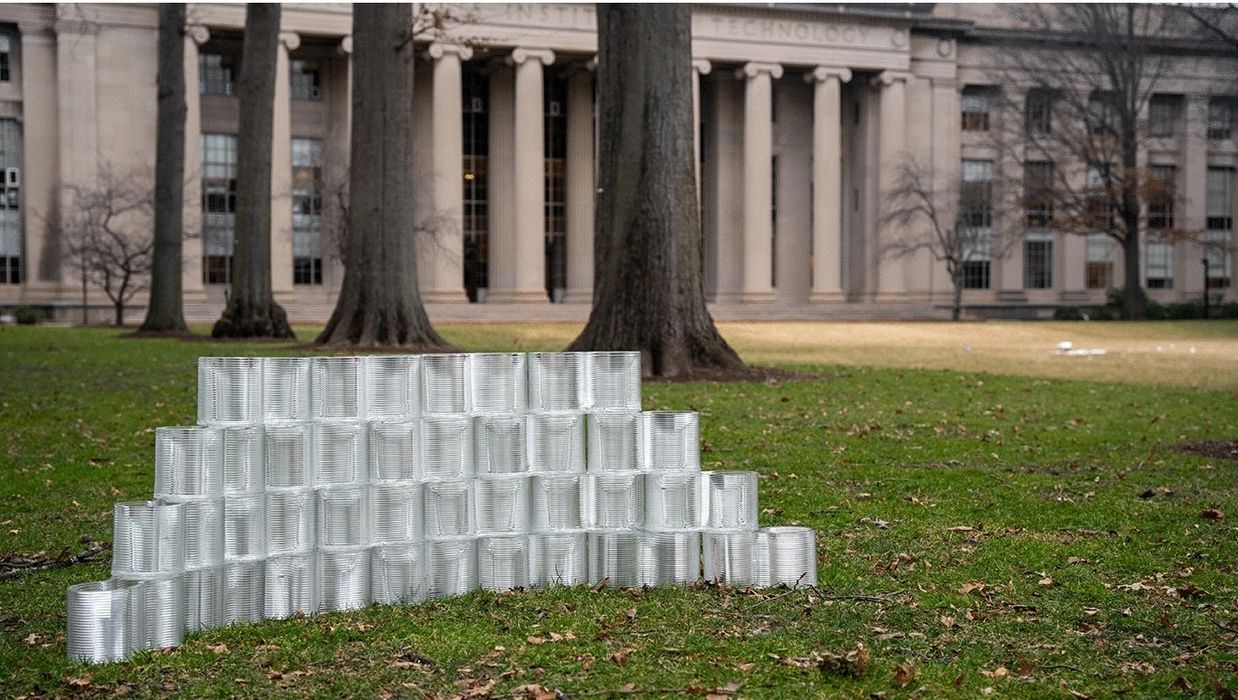

These designs would include methods of interlocking blocks together that could form a wide range of structures. They also investigated manufacturing techniques, recycling opportunities — including disassembly, and much more.

Why 3D print these items? There is a need for blocks to be hollow, because solid blocks would weigh far too much. Current cast blocks are not certified for structural use due to buckling. However, it is possible to 3D print blocks that are sufficiently strong.

There is also the possibility of varying the mix during printing to obtain different color textures, or other properties.

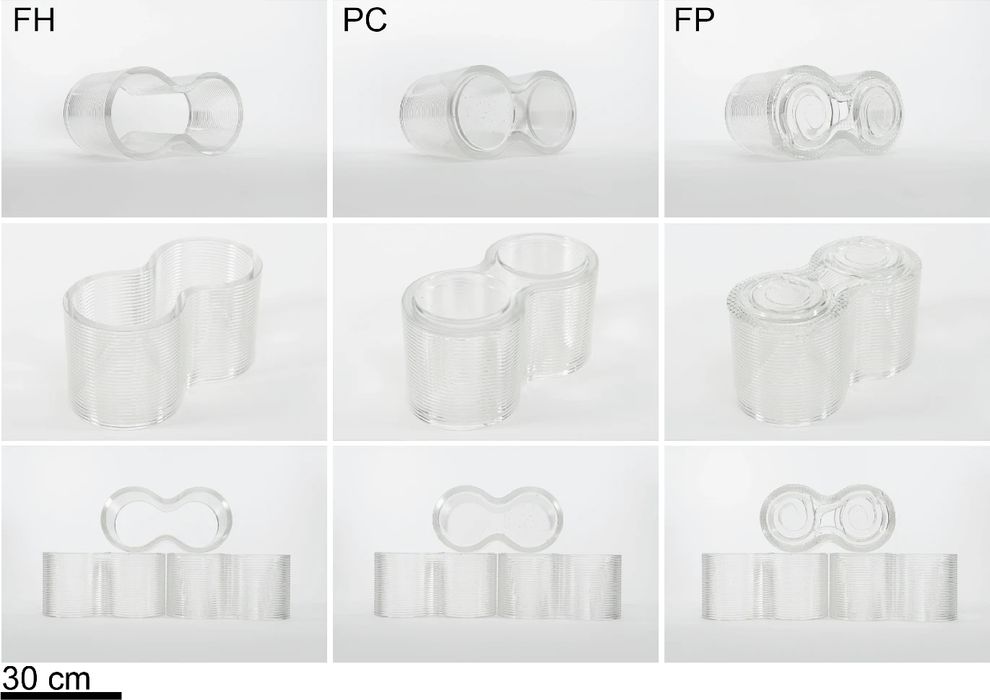

For their experiments they used G3DP3 glass 3D printer from Evenline, which has mostly been used to produce glass masonry items. Three different approaches for printing and block attachment were tested.

They found that a fully hollow approach worked best:

“After testing each of their performances and evaluating all the results, it was observed that FH units yielded the highest load to failure, the shortest production time, and the most accurate and repeatable manufacturing process.”

Future work will likely involve examining further design variations of the fully hollow approach to enable separate interlocking elements.

Should this approach be more fully developed, it is conceivable that we may see glass buildings rise using “3DGP”.

Via Springer