Developments in micro 3D printing continue.

While much of the media space is taken up by traditional 3D printing of mechanical parts, there is another domain of the technology that has quietly been increasing in usage and capabilities: micro 3D printing.

Micro 3D printing refers to any technology that enables the printing of very small parts. There are several companies producing equipment that performs micro 3D printing, including BMF, UpNano, Nano Dimension and several others.

Micro 3D printing is increasing in use as manufacturers continue to develop ever-smaller and more compact products. Smaller products are more lightweight, which is important in aerospace, can operate in previously inaccessible spots, and take up less space for shipping. Micro 3D printing is slowly being discovered by product manufacturers and is used to create new products.

This week there were two developments in this field.

UpNano announced a significant investment from backers to expand the company. They received €7M (US$7.6M) from a consortium of European investors. UpNano explained what they’re going to do with this new cash:

“The funds raised will allow UpNano to accelerate the development of its next generation 2-photon polymerization (2PP) 3D printing technology at a time when this innovative technology is becoming an integral part of many industrial processes.”

Two photon polymerization (2PP) is a popular 3D printing approach for micro-level operations. It involves moving a laser focal point in 3D space within a vat of transparent resin. It’s capable of printing extremely small structures.

Another competitor in the micro 3D printing space is BMF (Boston Micro Fabrication), which produces both machines and materials capable of making very small parts.

This week they announced the availability of four new advanced materials for their equipment. These include:

- 3D Systems Figure 4 HI TEMP 300-AMB: For parts used in “extreme thermal environments”

- BASF Ultracur3D 3280: A ceramic resin with a very high heat deflection temperature

- HTF (High-Temp): Another high temperature resin, with heat deflection temperature of 152C

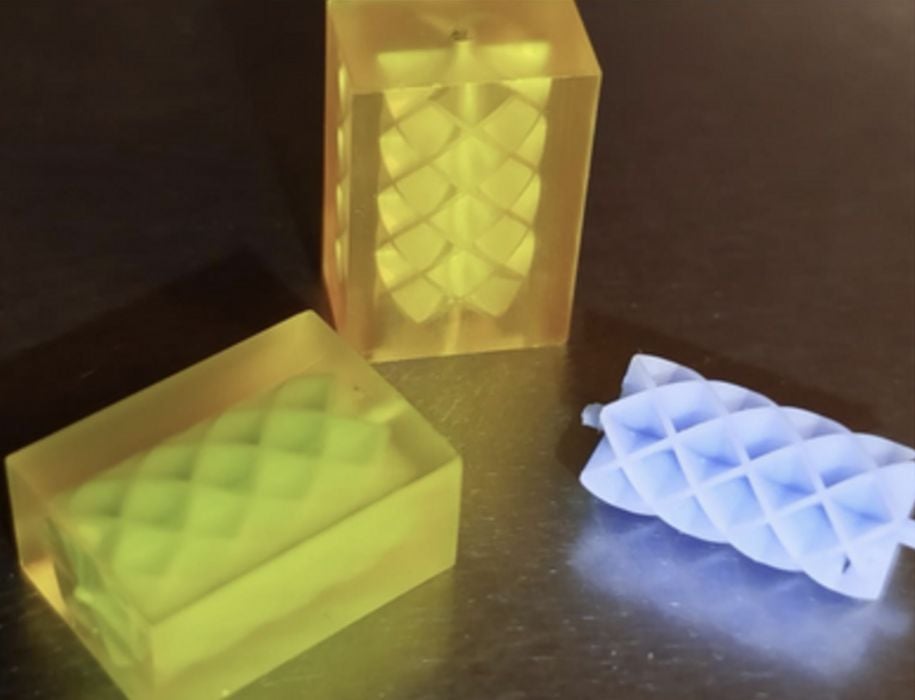

- SR (Sacrificial Resin): For single-use molds

The SR resin is perhaps the most interesting, as it enables the possibility of producing tiny molds for micro casting. This would allow the production of tiny parts in a very wide range of materials, beyond those printable with BMF equipment directly.

Also of note is that two of the resins are made by other parties, BASF and 3D Systems. This demonstrates that BMF has been testing a range of third party resins in their equipment and is beginning to certify and support their use.