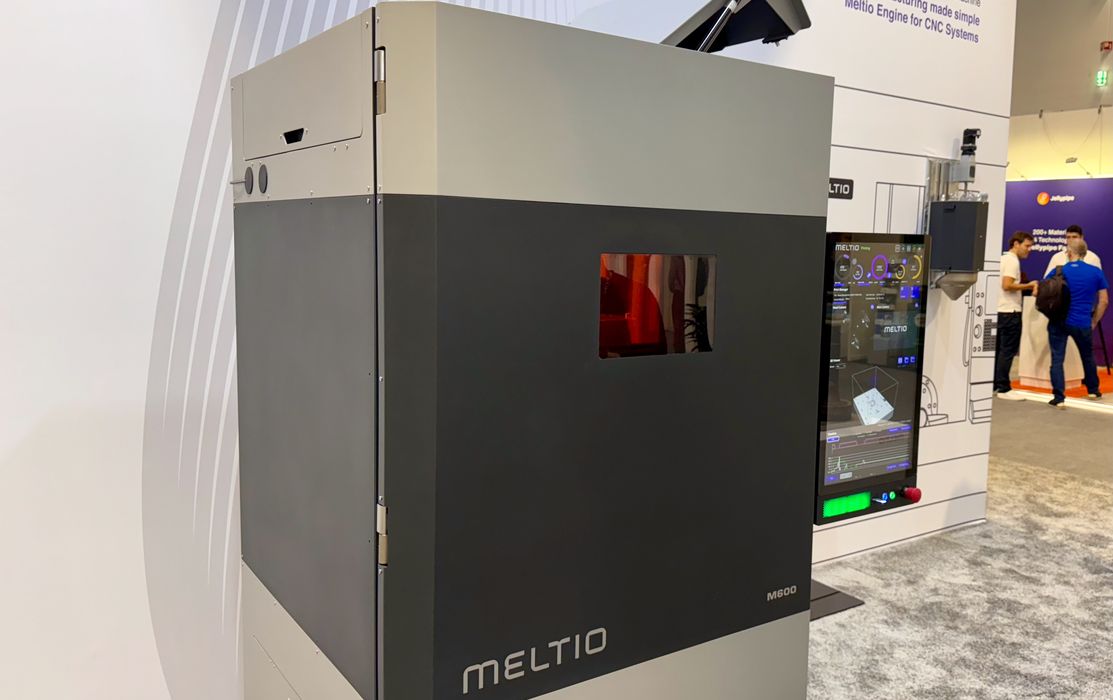

Meltio’s new M600 metal 3D printer uses blue lasers.

The M600 is an industrial metal 3D printer that uses standard welding wire as its input material. This allows for a very wide range of relatively inexpensive materials that already exist — and some are already certified for specific applications.

The big feature is the use of 1kW blue lasers instead of the more common red lasers. What’s the big deal about blue light? Meltio explained that it’s all about energy absorption.

They’re currently tuning the system to 3D print copper alloys, which are notoriously challenging to 3D print on most any 3D printer. This is due to the terrific thermal conductivity of the metal.

Meltio explained that the blue laser allows for increased energy absorption, which is more ideal for metals like copper, aluminum, inconel and titanium. Meltio explained that it is extremely difficult to print narrow walls, and that’s what they seem to be tuning at this point.

The M600 seems to be quite a capable machine. Designed for production use, it is able to handle up to four spools of different materials during a print job.

It is also possible to use large 200kg spools of metal welding wire with a special wire drum adapter. This would enable the M600 to print continuously for a very long time.

Finally, the M600 is also able to perform metal repairs on existing parts. It is, after all, a welder on a robotic arm. By carefully positioning the part on the platform with hold downs, the M600 can use its own 3-axis probing system to identify the geometry and proceed with repairs safely.

Via Meltio