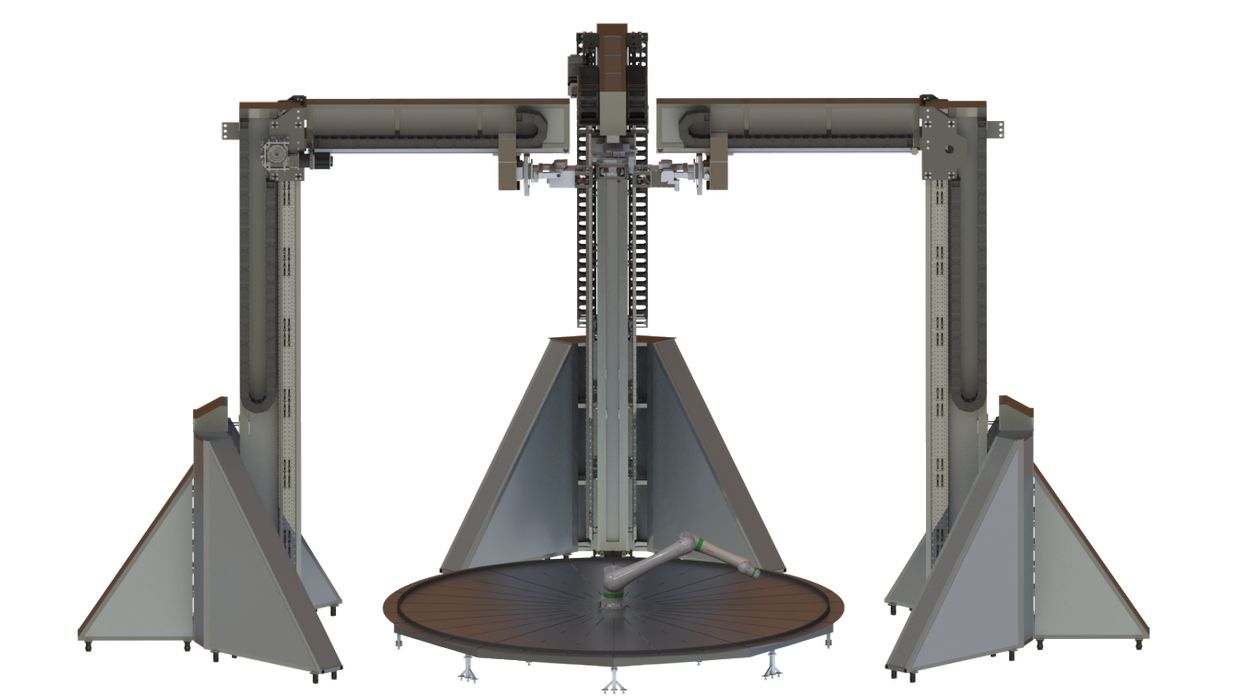

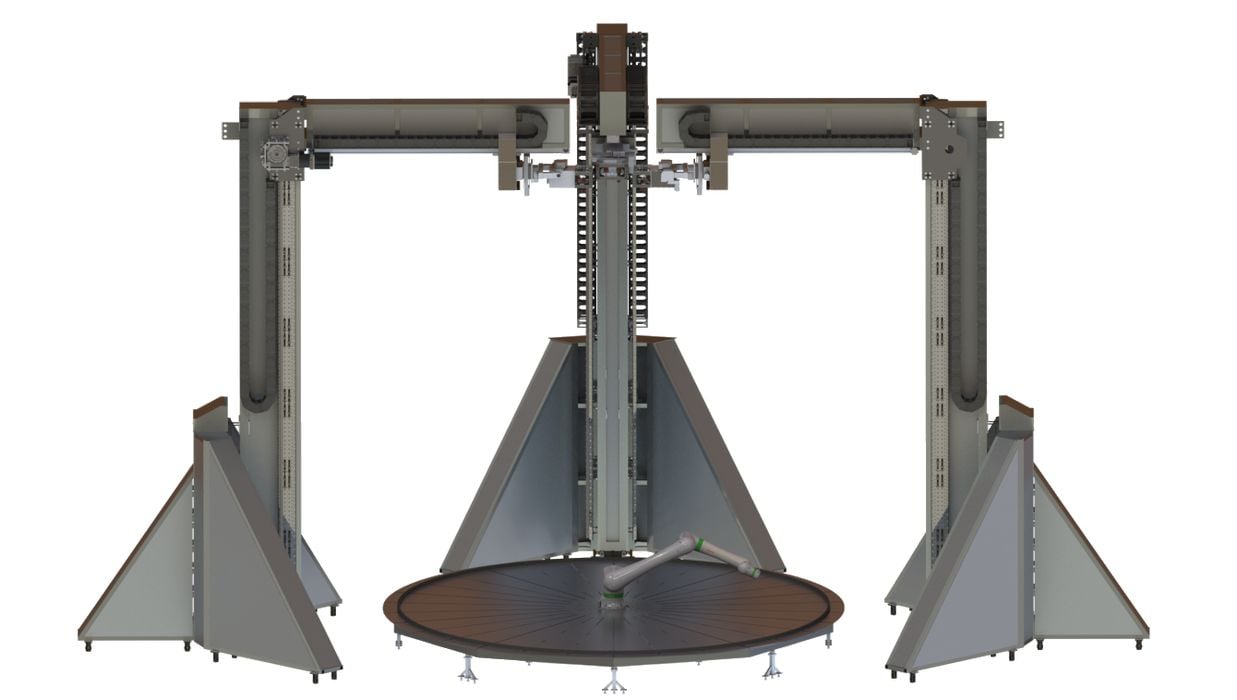

A rather unusual metal 3D printer has been announced by Rosotics, the Halo.

Rosotics is a five year old startup company based in Arizona, focused on development of large-format metal 3D printing solutions. Their mission:

“Rosotics produces hyper-efficient metal additive manufacturing solutions to solve the toughest challenges in industrial engineering. With our platforms, we enable industry to additively manufacture large-scale structures using far less energy and material resource than any other alternative in practice.”

Halo, according to Rosotics, is the “largest commercial metal 3D printer in the world”. This is no doubt a true statement, as the build volume of the Halo is a whopping 4953mm diameter by 6020mm tall. In fact, the Halo can print objects that weigh as much as 20t.

Their technology is quite different from the typical LPBF approach used by many metal 3D printer manufacturers. Instead they use a metal wire approach, where a wire is extruded from a robotic toolhead and then instantly melted.

Unlike other wire approaches that use lasers or electrical arcs to melt the metal, Halo uses an inductive heating approach. This is implemented in their Mjolnir toolheads, of which three are installed on the Halo system. Again, this seems to be the only system on the market using inductive heating.

Why inductive heating? Rosotics explains:

“Halo is laser and powder free, is safe for humans, and is highly energy efficient – enough to reduce CO2 footprint per 500 kg of printed mass by over 86% when compared to WAAM.”

In other words, inductive heating requires far less electricity to melt the metal than do lasers or electrical arcs. That could be a considerable advantage for Rosotics in the future when energy consumption becomes far more important.

They don’t explain the details, but it appears that the Halo has significant internal feedback mechanisms to “intervene as necessary in order to prevent or correct mistakes”. It may be that they could be using some form of AI to help with this aspect. That’s even more likely with this statement from the company:

“Over time, your system will be able to operate fully autonomously with the ability to manufacture or repair any structure.”

There’s another very intriguing feature of the Halo: it is apparently “self assembling” and can be set up within a single day.

This is quite interesting. It appears that they make use of the robotic arms to help build the machine itself. Very likely there is a basic setup to enable some robotics, and then the system does the rest. I’m interested to see a video of this process.

The company is initially focusing on the aerospace and defense industries, which certainly have requirements to build large metal parts.

One detail that I truly appreciate is their sales approach. While almost every other industrial 3D printer manufacturer will have a “click here to contact us” button and subsequent negotiations over pricing, Rosotics does it very differently:

Yes, they have an “Order Now” button. Easy to click, but make sure you have US$1M in your wallet.

Via Rosotics