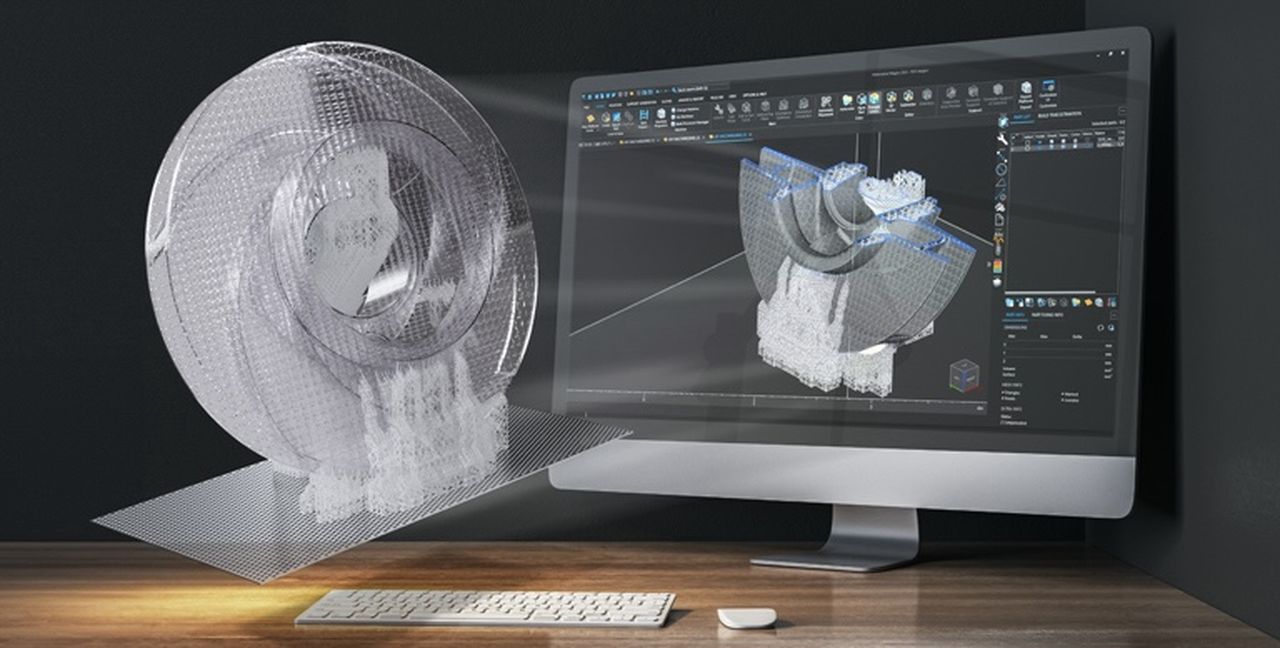

Stratasys Neo Build Processor for Investment Casting developed for Stratasys Neo 450 and Neo 800 SLA 3D printers.

Materialise and Stratasys have teamed up to launch the Stratasys Neo Build Processor for Investment Casting, a new software solution designed to accelerate the production of high-quality investment casting master patterns.

Developed for the Stratasys Neo 450 and Neo 800 stereolithography (SLA) 3D printers, the companies claim the new tool offers up to 50% faster file processing and significantly enhanced print speeds.

3D printing master patterns can reduce the investment casting production time from weeks to days. According to Materialise and Stratasys, the result can be up to 75% time savings compared to traditional methods of manufacturing, such as wax molds and CNC machining. The ability to produce intricate designs that are not possible with conventional techniques is particularly useful for small-series production runs.

The Stratasys Neo Build Processor for Investment Casting is primarily intended for manufacturers in the aerospace and automotive industries, where speed, precision and cost-effectiveness are paramount. Materialise and Stratasys state that combining Somos WaterShed AF resin, Neo SLA technology and advanced Materialise software with the variable layer thickness feature enables manufacturers to produces highly accurate 3D printed master patterns requiring minimal finishing.

“This new build processor advances our mission to provide faster, more efficient solutions for producing high-quality master patterns,” said Rani Hagag, chief healthcare and consumer business officer at Stratasys in a press release. “Partnering with Materialise exemplifies how Stratasys collaborates with industry leaders to drive innovation and help our customers achieve their most challenging production goals with greater speed and precision.”

Materialise’s NxG Build Processor is a configurable software that translates large and complex 3D design files into 3D printable instructions with the aim of optimizing the 3D printing process from start to finish.

Notable features of the new build processor include:

- Faster File Processing and Printing Speeds: Offloading computational tasks to the build processor helps optimize file preparation without compromising part integrity.

- Improved Workflow Integration: The processor integrates with Materialise’s Lattice module and Stratasys’s Titanium software for Neo systems to minimize human error.

- Superior Part Quality: The advanced variable layer thickness options are designed to produce stable, high-quality master patterns.

- Customizable Build Parameters: Customizable parameters for geometry, supports and lattices are intended to support faster scanning and improved productivity.

Read the rest of this story at ENGINEERING.com