Markforged announced the “Metal Kit” to transform their FX10 3D printer into a hybrid metal device.

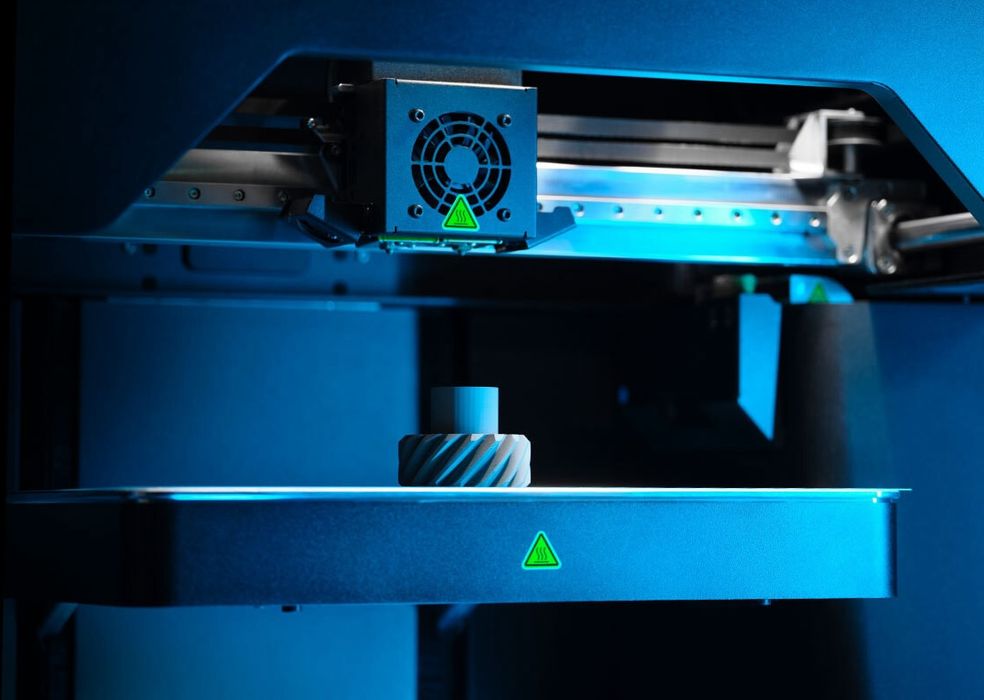

The FX10, announced last year, is specifically designed for 3D printing composite materials, such as carbon fiber or glass fiber infused filaments. These materials offer notably stronger properties, and are highly desirable for production parts.

Markforged is no stranger to metal 3D printing, as they’ve had their Metal X device on the market for several years. This 3D printer uses the FFF process to print metal infused filament. The “green” parts that are printed undergo a post printing process to remove the polymer binder, and then sinter the remaining metal particles together into a solid object. The process is able to make very good quality metal objects, although operators must account for shrinkage during post processing.

A company wanting to print both composites and metal parts using Markforged technology would have to get both of these machines, the FX10 and Metal X.

That’s expensive, especially if you are only doing one of the materials occasionally.

Now Markforged has solved the dilemma with the Metal Kit. It’s basically a swappable toolhead system, where you can change from metal to composite operations in as little as 15 minutes.

The kit consists of the print engine, feed tubes and pre-extruders, all of which must be different when handling metal filaments.

This means that FX10 customers can at low cost suddenly have metal 3D printing capability without the need to purchase a second 3D printer. However, they will have to purchase a sintering unit to post process metal prints.

“Metal prints are built from the metal filament and a ceramic release filament. The ceramic release is extruded as an interface between the part and supports for ease of separation and removal. Once metal prints are complete, they must be washed and sintered in Markforged’s Wash-1 and Sinter-2 solutions. Eiger, Markforged’s slicer and print management software automates the process, including scaling parts to account for shrinkage during sinter.”

It also turns out that printing metal parts on the FX10 is a better experience than their previous Metal X system. Markforged explains:

“Similar to the 5th Generation Continuous Fiber Reinforcement (CFR) print system in the FX10 that prints nearly twice as fast as previous composite printers, the 2nd Generation Metal FFF engine, built on years of Markforged’s experience printing metal, prints significantly faster than previous Markforged metal systems. FX10 combines faster print speed with a print volume twice as large compared to Markforged’s prior industrial metal printers.”

The new Metal Kit will be of significant interest to many FX10 3D printer operators, and could also attract new buyers seeking the ability to occasionally make metal parts at a relatively low entry cost.

Via Markforged