Preeti Sulibhavi and Maya Gerber dive into the impact of 3D printing on competitive swimming, revealing how technology is driving innovation in gear and accessibility.

Every four years, the cycle of the Olympic Games produces an increased interest in competitive swimming. Like clockwork, the number of registered US swimmers increases every four years, many inspired by the athletes they see competing on an international stage. The global swimming equipment market has grown to US$12.4 billion in 2022, with that number predicted to grow after this summer’s games in Paris. This industry has begun to dive into the world of 3D printing, but there are more opportunities to present.

Setting the Pace

Two of the largest and most trusted swimming equipment brands are Speedo and FINIS Inc, and both companies have started to develop 3D printed products. Both companies have reputations of being ahead of the competition when it comes to innovative swimming

Equipment. Their integration of 3D printing is no different. Specifically, FINIS has been utilizing filament 3D printing for rapid prototyping. This technique has been used

specifically, to craft goggles, with adjustable straps and for increased comfort. 3D printing allows for designs of different materials to be printed and tested directly in the pool in a day or less.

Speedo has specifically designed Aqualab, which is their confidential research and

innovation facility that is dedicated to developing the newest technology in swimming gear. In an all-female led team, the Aqualab is a global R&D facility that is responsible for some of the most innovative swimming products in the world, with the help of 3D printing technology.

During the Paris 2024 Olympics, over half (50.3) of the medalists in swimming were sporting Speedo swimsuits, ones that were developed using 3D printing and Aqualab. This

includes 11 Olympic records, and the single world record broken in Paris was in a Speedo swimsuit. By utilizing 3D Printing, Speedo is changing the sport of swimming by introducing innovative products.

Inspiring 3D Printing Projects

3D printing has also been able to help those who are physically disabled. An inspiring example of this is a sixteen-year-old boy from Spain, Pedro, who loved to swim but found it difficult after a stroke that left his hand immobile. The solution came from BCN3D a 3D printing company that produced the custom-fit hand paddle for Pedro. 3D printing the paddle enabled the design and development process to be more streamlined and efficient than traditional R&D procedures, and all the materials for the paddle were more cost-effective.

Outside of competitive swimming, 3D printing can be used to develop tools to help teach young children how to swim. At a swim school in the Netherlands, 3D printing is being

utilized to create puzzles and toys to help encourage young swimmers. More specifically, due to 3D printing’s rapid development, each child can get their toys depending on their specific needs.

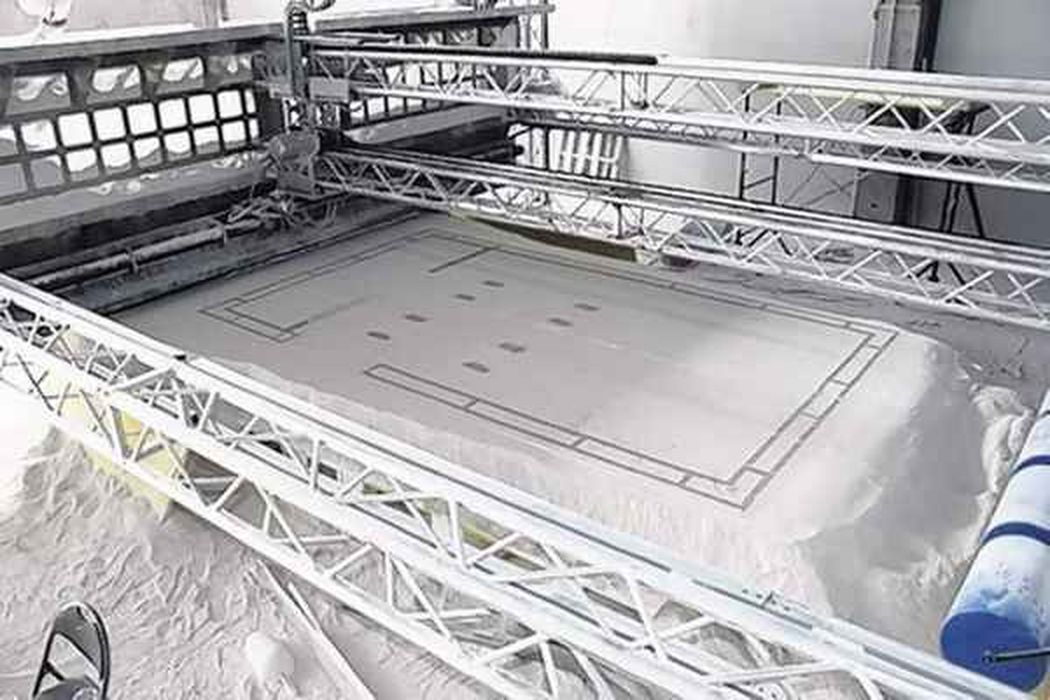

On an even larger scale, pools have been made from large-scale 3D printers. The pool (depicted below) is estimated to cost less than constructing a typical pool, as there are no labor costs. We have covered 3D printing with cement or concrete on Fabbaloo before. With the development of waterproof and chlorine-proof 3D printing materials, this production method may be the wave of the future.

The R&D Tax Credit

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of

eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible

activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The intersection of 3D printing technology and the swimming industry is creating waves of innovation and opportunity. From major brands like Speedo and FINIS leveraging rapid prototyping for product development to inspiring projects that enhance accessibility for

disabled swimmers, 3D printing is revolutionizing the way swimming equipment is designed and manufactured. The technology’s potential extends beyond swimming gear, having applications for pool construction and educational tools for young swimmers.

As the swimming equipment market continues to grow, 3D printing offers a path to more personalized, efficient, and cost-effective solutions. Moreover, companies embracing this technology may find additional benefits through R&D tax credits, further incentivizing

innovation in the field.

Looking ahead, the fusion of 3D printing and swimming technology promises to drive the sport forward, potentially leading to better performance, increased accessibility, and more sustainable manufacturing practices.