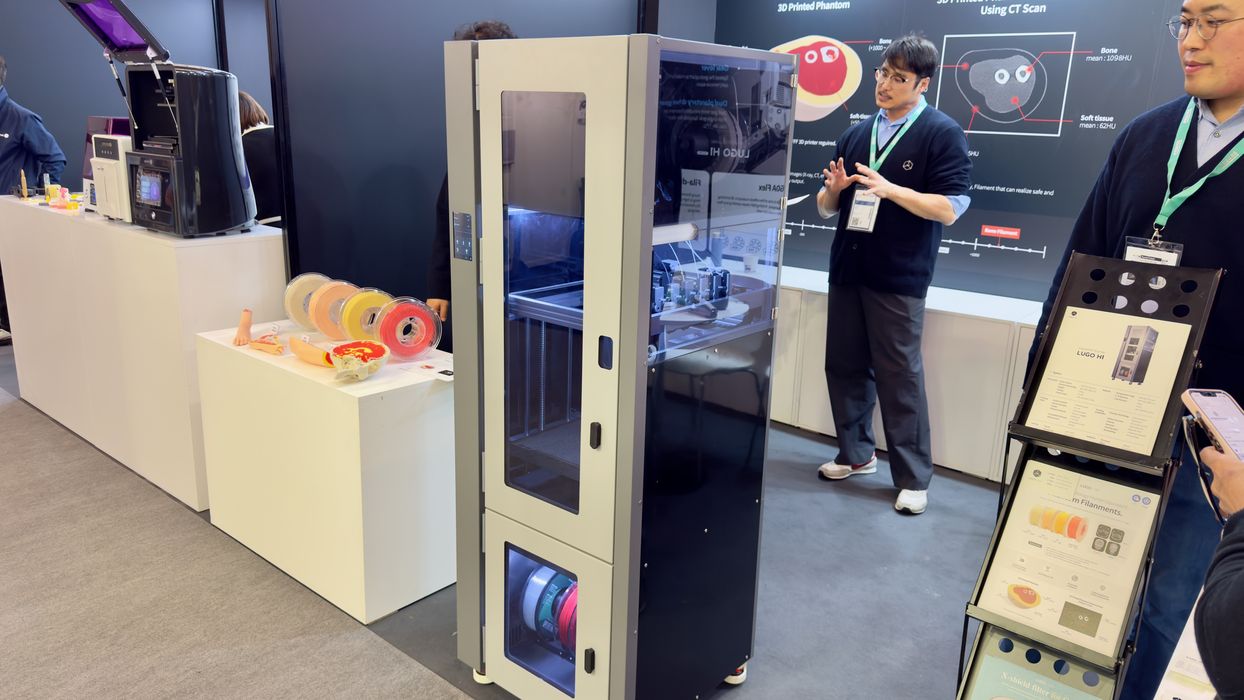

I had a look at an interesting toolchanging 3D printer from Lugo Labs.

Korea-based Formers Farm has produced 3D printers under the Lugo Labs brand since 2013, and we last saw them in 2019. Recently, they’ve been focusing on 3D printers for the dental industry, but their latest device, the LUGO H1, offers something for the rest of us.

The H1’s unique feature is that it is a toolchanger that includes six printheads. A toolchanger differs from a single-head multicolor machine in that there are actually six toolheads, not just one that uses different filaments.

As the print proceeds, the motion system grabs one of the printheads and begins printing with it. The filament is already loaded on incoming printheads, and it’s preheated and ready to print. This avoids filament switching delays, as well as wasted material from purging that is required to clear single nozzle systems. In other words, it will print multicolor objects far faster.

The really interesting part is the manner in which Lugo Labs has designed the toolchanging system. Above, you can see the arrangement, where the printheads are stored on the right while awaiting use.

To pick them up, the tool simply moves over, and they snap on, taking only seconds. The same happens when releasing a printhead back to the stowage position.

Unlike most toolchangers that include heavy motors, the H1’s design just has a hot end. Above, you can see two examples of these printheads. They’re basically just the hot end and have a gear for drive motion.

This approach removes the need for six motors, and that makes the system more economical to operate.

I asked about the alignment problem. This happens on every toolchanging machine: how can you ensure that the new printhead is perfectly aligned with the previous toolhead? If it isn’t, then material will be deposited with an offset.

Lugo Labs’ solution is brilliant: the design of the printhead is such that it cannot be mounted in the wrong position: it fits directly into the tool in only one precise position. Similarly, the Z-gap is identical after swapping printheads.

Swapping the toolheads is quite simple. Here you can see it’s done with a simple press of a lever, and can be done in seconds.

Another interesting feature is that the printheads can be either 1.75 or 2.85 mm versions — in the same print job! I’ve never seen a 3D printer able to do this, but for those with a mixed set of materials, it could be ideal.

The Lugo Labs H1 is a professional multimaterial 3D printer that has some unique features.

Via Lugo Labs