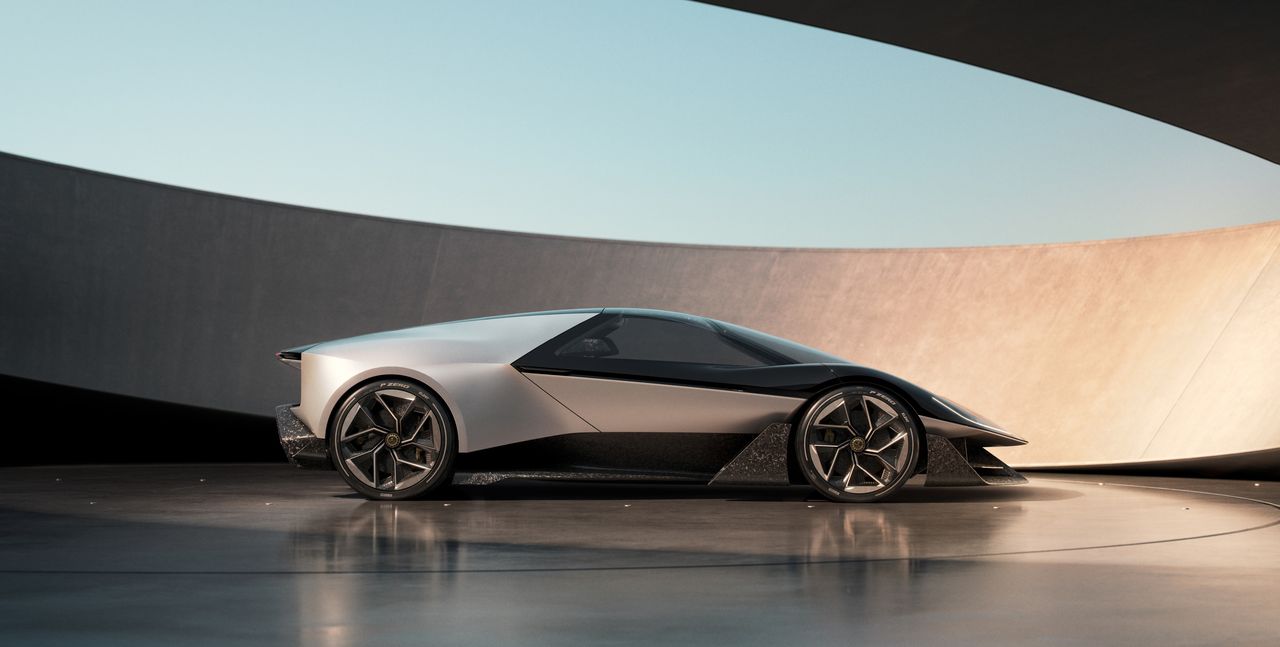

Carbon worked with Lotus to create a unique 3D printed headrest on their new supercar, the Theory 1.

The Theory 1 is an experimental EV demonstration vehicle through which the company will identify new technologies and approaches for designing and building a supercar, or as they call it, “intelligent performance vehicles”.

The Theory 1’s design includes a range of unusual features in their “LOTUSWEAR” package, including multiple drive modes that automatically adapt to the environment, enhanced “speed sounds”, noise cancelling, tactic feedback on the steering wheel, and much more.

One of the new features is a peculiar headrest, shown here.

It turns out that this headrest was 3D printed using Carbon technology and materials.

The headrest is a complex lattice, which was no doubt designed in Carbon’s extensive software package. Carbon produced the software to help manufacturers easily create complex lattice designs for 3D printing.

Lotus explains:

“In addition, LOTUSWEAR features 3D printed lattice structure headrests made in partnership with global 3D printing technology company Carbon, to offer all occupants in the car maximum comfort, whilst reducing the weight, improving material efficiency, and optimising aerodynamics.”

This is an excellent example of how a 3D printed structure can replace traditional foam components, and unlike most foam-replacement applications, this one is entirely visible.

Theory 1 is an experiment, so it won’t be mass produced, and it’s not for sale. It is for proving out the technologies, and it’s quite possible that the testing may show the headrest to be a viable component. If so, then Carbon could be in line to provide substantial equipment to Lotus for their production lines.

This is how 3D print applications happen: an idea becomes an experiment, and if it works the process is scaled up.