Lithoz announced a notable achievement: a human implantation of a ceramic part.

The Austrian company produces high-end equipment designed to 3D print in a variety of ceramic materials. Ceramics are quite different from the more typical polymers and metals, in that ceramics have high thermal resistance, electrically insulative, and significant chemical resistance.

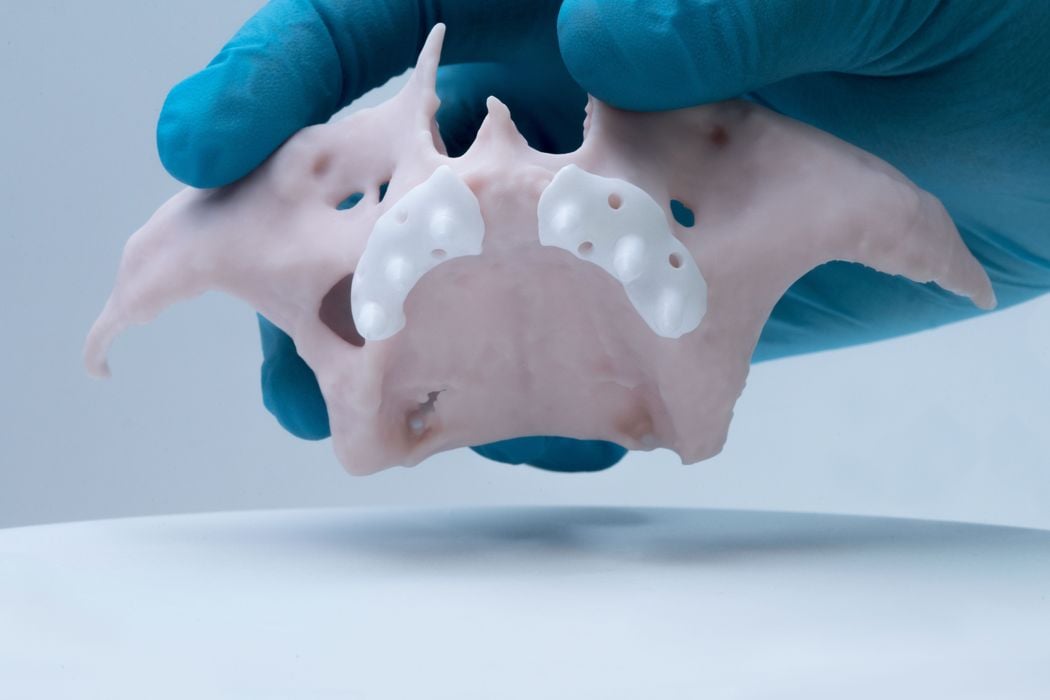

There are many applications for ceramics, quite a few that have yet to be explored. One that seems to be now proven is the use of ceramics for human implants, at least in this case for a subperiosteal jaw implant.

3D printed implants are by no means a new thing. There are, in fact, many metal 3D print services that make considerable revenue by producing hip joints and similar implants. But ceramics, as far as I know, have not been used in implants until now.

The experimental implant developed by the EU INKplant project involved a patient’s jaw, which had deteriorated due to the age of the patient and loss of teeth. Lithoz explains:

“The implant was developed with and built by Austrian ceramic 3D printing specialist Lithoz to address the issue of atrophic jaws, a common problem in older patients. After the loss of teeth, the jawbone disappears as well, resulting in atrophic jaws and rendering the use of dentures impossible. With severe atrophy, conventional dental implants require additional lengthy operations to graft new bone to anchor the implants. Such operations are difficult for elderly patients who cannot undergo bone grafting due to health issues.”

The Austrian patient in question had previously used traditional treatments, including bone grafts, which did not work. That opened the possibility of using the experimental ceramic implant.

The ceramic implant was developed by Lithoz and other partners was made from a special biocompatible high strength zirconia material, and printed with Lithoz’s LCM process.

Interestingly, the implant was significantly less complex than the traditional treatments, apparently requiring only a single procedure and reducing recovery time by a massive 75%. It seems that the ceramic works far better with soft tissue than traditional titanium. After only 60 days the implant was considered to have “clinical stability”.

This could be a major breakthrough for implants, which are typically done with metals today. Ceramic may enable similar savings and benefits for other types of implants. After the success of this procedure, it seems clear that researchers will investigate additional implant possibilities.

That’s good news for 3D printed ceramics, and specifically for Lithoz.

Via Lithoz