The KeratOPrinter hopes to solve corneal blindness with new technology.

Corneal blindness, or corneal opacity, is a very common condition occurring in older people. The cornea on the outside of the eye becomes gradually less transparent, obscuring the vision of the patient.

Today, the most common approach for solving the problem is keratoplasty, or a corneal transplant. The opaque cornea is removed and replaced with donor tissue that is transparent. There are some other treatments, but usually for less severe cases.

While keratoplasty does work, it depends utterly on the availability of donor corneas. They are in short supply, meaning patients have a long waiting list for the surgery.

Enter the KeratOprinter. It’s an EU-funded project (€8M) to develop a specialized bioprinter that can produce replacement corneas. These would then take the place of donated human corneas in keratoplasty treatments.

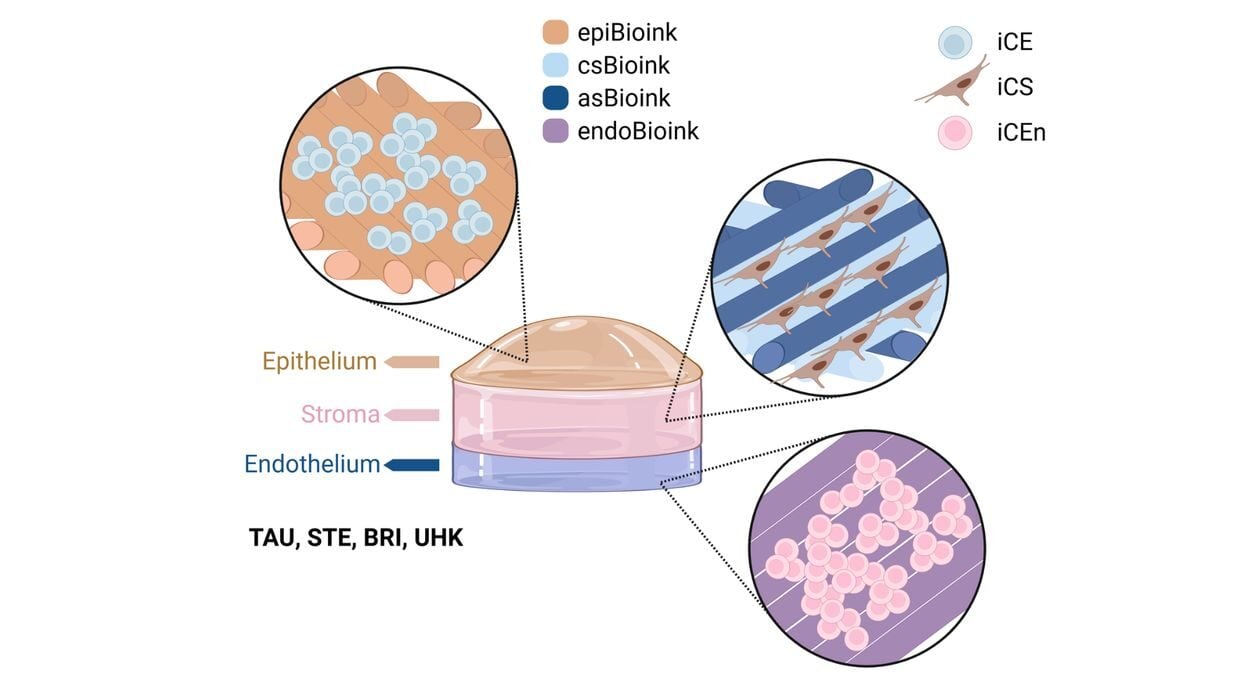

How does it work? This is quite interesting. The cornea is composed of three types of cells:

- Corneal epithelial cells (outermost layer)

- Stromal keratocytes (middle, structural layer)

- Endothelial cells (inner layer that maintains hydration and transparency)

The project intends to create supplies of these cells through the use of human induced pluripotent stem cells (hiPSCs). These are stem cells that can be programmed to produce specific human cell types, and they will need three different programs to produce the required cells.

The supply of cells is then mixed into bioinks that are used in a specialized “laser-assisted bioprinter” that builds a replacement cornea with the cells in the appropriate places. The completed corneas would likely undergo some post-processing and ultimately be transplanted into a patient.

At this stage, it seems that the project is just getting underway, as they don’t appear to have any hardware to display. However, the concept seems technically valid and worthy of exploration.

The concept also seems quite suitable for 3D printing as it addresses a situation similar to other successful 3D print applications:

- Customized “parts” for the buyer

- Expensive current approach

This business formula has worked very well in aerospace and dental industries, and it would seem the same for cornea printing. In addition, the shortage of donors means there is a significant demand for the technology.

While that all sounds very good, KeratOprinter has a long way to go. They have to not only develop the technology but also undergo a long certification process to ensure it works properly with humans. That will no doubt take several years to complete, but at the end, they could have a very significant business opportunity that will solve vision issues for countless people around the world.

Via KeratOprinter