I’m reading a thread discussing the toxicity of 3D Gloop, a popular adhesive for 3D printed parts.

These days, many 3D models involve multiple parts, and often they must be glued together. Traditionally, superglue has been used by desktop 3D printer operators to affix parts together. Recently, there have been some 3D print-specific glues appearing on the market, one of them is 3D Gloop.

3D Gloop is actually a brand that covers a series of different adhesives. They offer “gloop” for PLA, PETG, and ABS materials, which are the most commonly used by desktop FFF 3D printers. Why buy 3D Gloop? It’s an incredibly powerful adhesive. They explain:

“3D Gloop is a specially formulated adhesive compound designed specifically for the plastics used by 3D Printers.

Okay, so we will just say it… 3D Gloop! is hands down the best adhesive for holding your PLA, PET-G, and ABS/ASA prints together. No more messy epoxies or super glues & activators that don’t work. With 3D Gloop! you will get the strongest and most reliable bond compared to any other adhesive on the market!”

How do they achieve this? It’s because they use a specific chemical in their formulation, Methylene Chloride. Rather than just bonding to the surface as do most glues, this chemical actually dissolves a depth of the material and truly fuses the parts together.

The problem is with this chemical, Methylene Chloride. In April last year, it was declared a “dangerous chemical” by the US EPA because exposure to it has resulted in dozens of deaths.

Case closed, it would appear; don’t use anything with Methylene Chloride, and that would include 3D Gloop, which according to their own SDS (Safety Data Sheet), is composed of 20-60% Methylene Chloride by weight.

But the truth seems to be a lot more complex.

In the discussion thread, a number of viewpoints are proposed. Some wish to avoid the 3D Gloop entirely, while others say it’s perfectly safe to use if appropriate precautions are used.

One of the key concepts is the amount of exposure. The substance was banned by the EPA because of fatalities, but those were cases in which significant exposure occurred. For example, the EPA describes one fatality that occurred when a worker was stripping a bathtub with (likely) a large quantity of the chemical.

That’s quite different than a couple of drops of glue.

If I were a new 3D printer operator looking for an adhesive solution and read that thread, I would be terribly confused. Should 3D Gloop be used or not? What are the proper safety precautions? What if they use 3D Gloop daily, would repeated exposures add up to a toxic level?

The truth is that 3D Gloop is safe to use — only if proper handling is employed. That’s where the problem lies.

The proper way to handle Methylene Chloride seems to be with suitable gloves, eye protection, a respirator, and ventilation.

My question is whether all 3D printer operators actually use these precautions. We’ve all seen the challenges with novice operators using resin 3D printers, and 3D Gloop is likely the same.

Complicating the situation is that apparently nitrile gloves, the go-to glove type for resin 3D printing, are not appropriate for handling Methylene Chloride. The chemical passes through those gloves, and I fear that many 3D printer operators may use the nitrile gloves because they might be handy. Gloves are gloves, aren’t they?

No, they are not.

3D Gloop’s SDS web page provides information on the products, but does not mention the nitrile glove issue, and in fact does not mention “gloves” at all. They merely say:

“Expert care and caution are required when handling, using, and storing PLA 3D Gloop!”

And:

“Keep locked up. Keep away from children. Keep away from heat. Keep away from sources of ignition. Empty containers pose a fire risk. Containers may become pressurized. Do not open the container pointing toward your face. Ground all equipment containing material. Do not ingest. Do not breathe gas/ fumes/ vapor/spray. In case of insufficient ventilation, wear suitable respiratory equipment. If ingested, seek medical advice immediately and show the container or the label. Avoid contact with skin and eyes.”

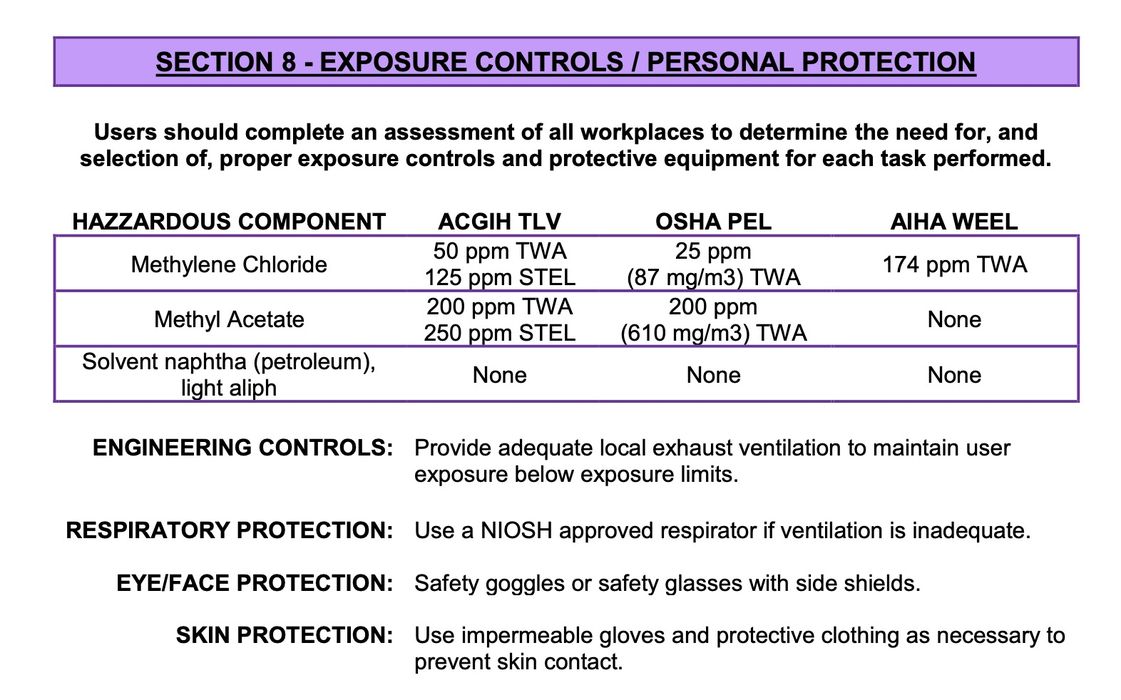

An operator reading that would have no idea that gloves should be used. They’d have to dig deeper into the formal SDS document, a PDF. There they would see this:

While that’s all technically correct, it doesn’t really tell an operator what to do. What kind of respirator is required? What type of “impermeable gloves” are the right type for this chemical? What is an “AIHA WEEL”?

For non-technical 3D printer operators, this is a problem. They cannot easily know what to do, as the 3D Gloop information doesn’t really explain what they should actually do. If they read the discussion thread or those similar to it, they would be subjected to a wide range of differing opinions and likely end up being confused.

You might say that if a person cannot properly understand the SDS, they shouldn’t use the product. That might be true, but these products are directed at the general public that may not have ever read an SDS or even heard of one.

An easy solution would be to just use superglue. It works very well for most applications, and the strength provided by 3D Gloop would only be required for parts that undergo significant mechanical force.